- The fixed arm positions the lens tube and cage system at a distance of 196.5 mm from the edge of the self-assembly system rail in the optical path.

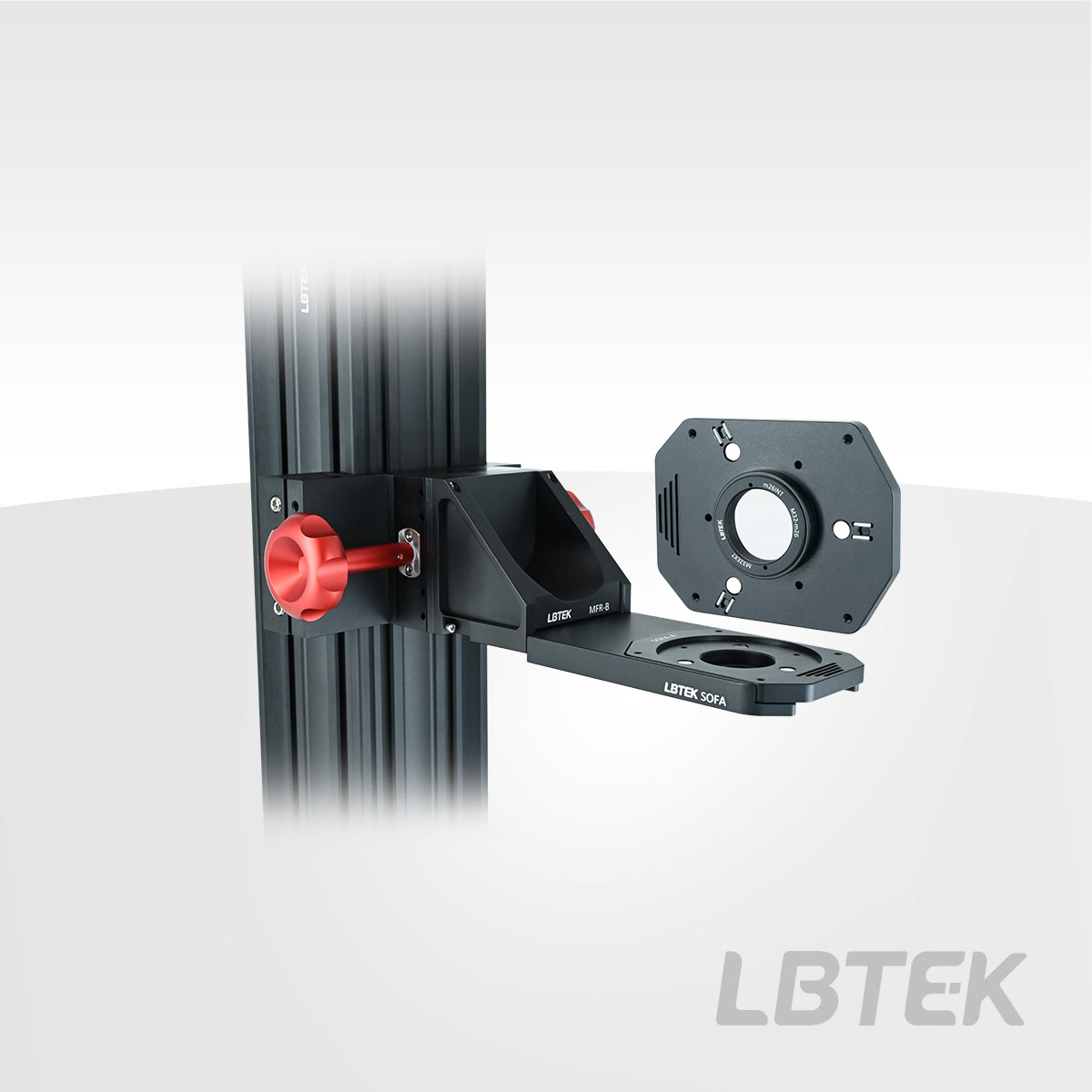

- The manual module moves the lens tube and cage system along the optical axis.

- The 95 mm rail mounting platform allows user-designed modules to be mounted to the microscope main body bracket.

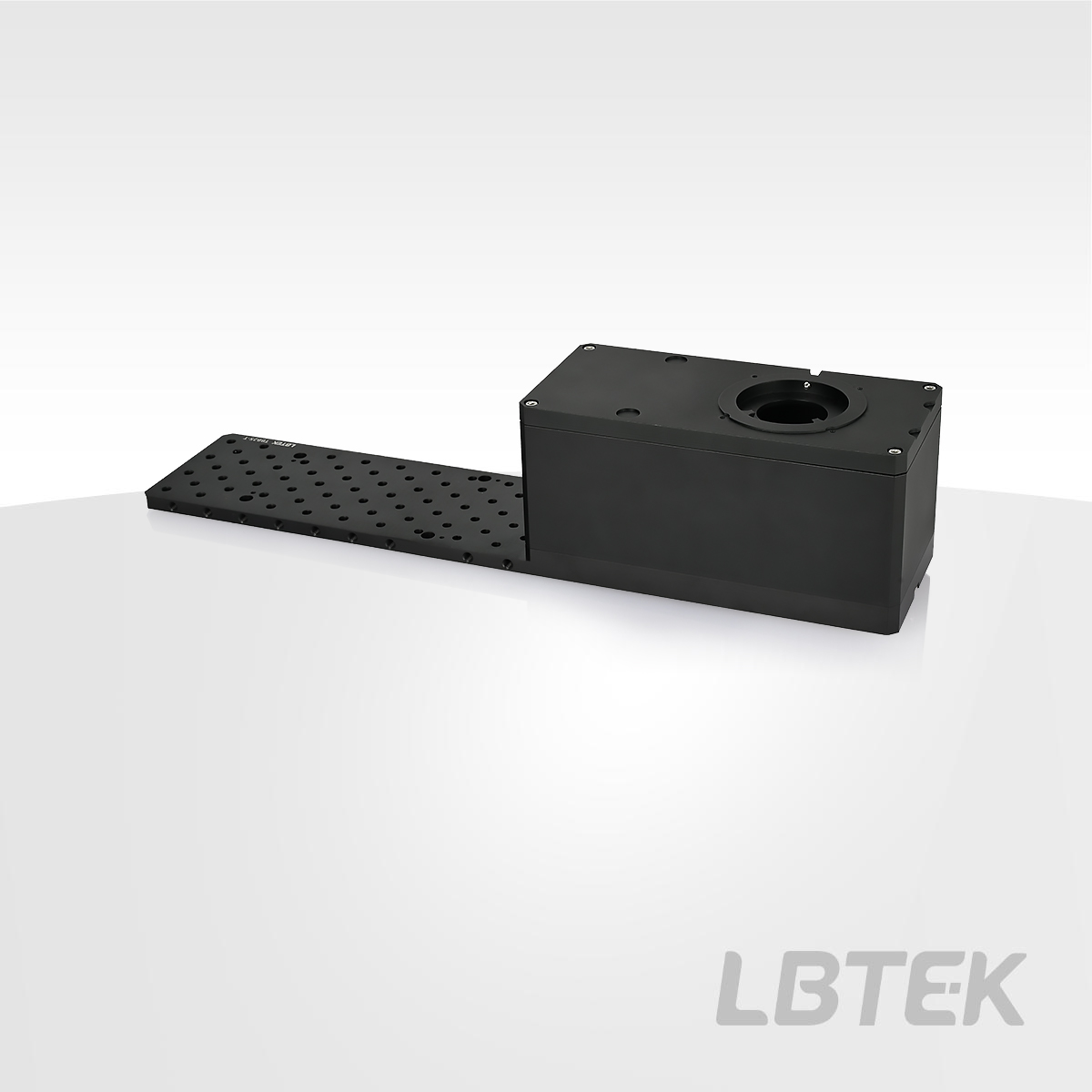

- The top breadboard supports custom sample observation and illumination paths.

- The epi-illuminator module integrates a filter cube with SM1 and 30 mm cage components.

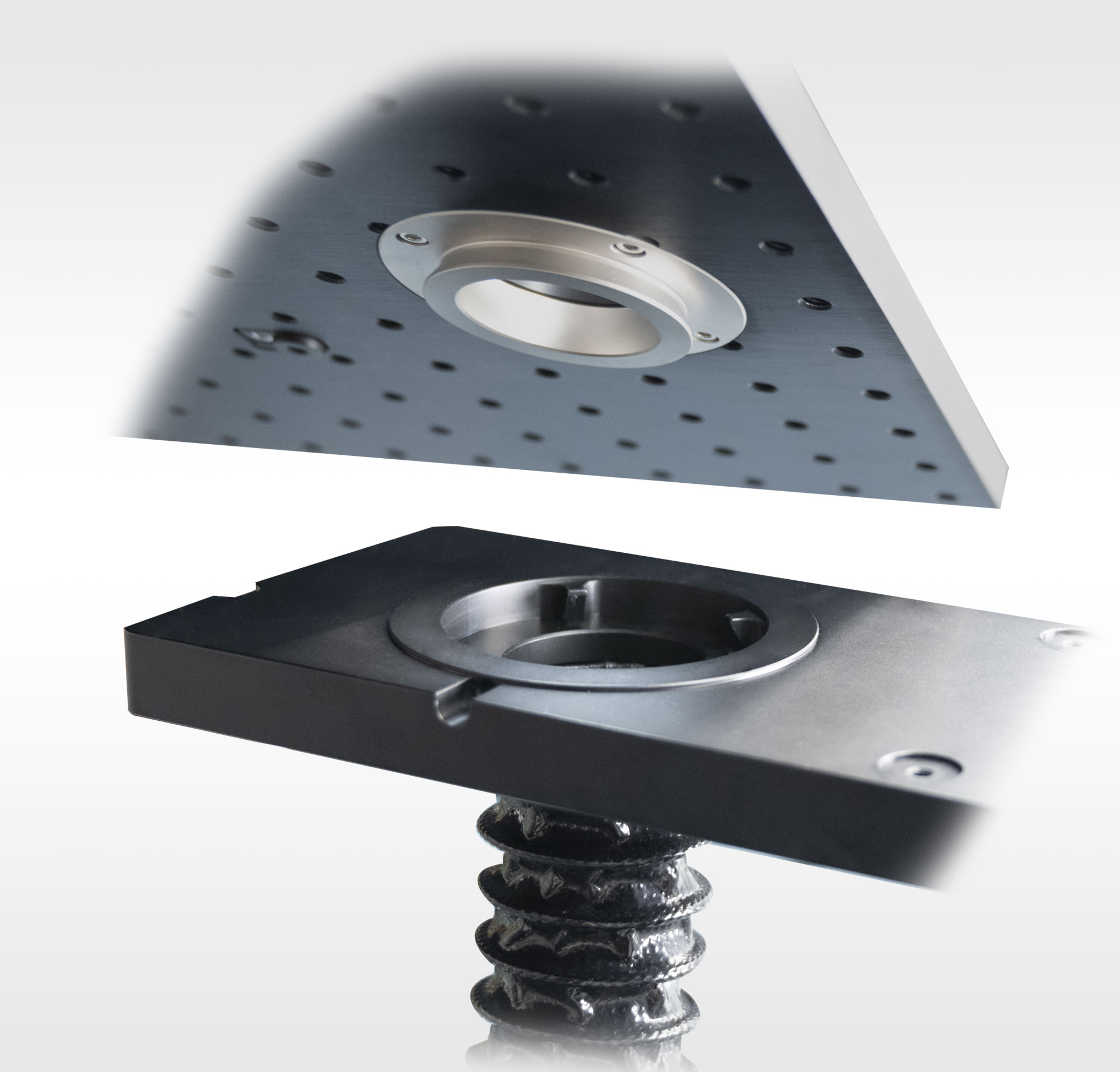

- The dovetail adapter connects the self-assembly microscope components to the lens tube and cage system.

- The 95 mm dovetail clamp on the back can be connected to the microscope main body bracket

- SM2 female threads and 4 M3 screw holes for 60 mm coaxial systems

- Optical port for light paths 196.5 mm from the edge of the microscope imaging system rail

The LBTEK Coaxial Arm, when mounted on the microscope main body bracket, can position the optical port at a distance of 196.5 mm from the edge of the vertical guide rail. The coaxial arm provides structural support for user-built optical paths and features a 95 mm dovetail clamp on the back. By tightening two 4 mm hex set screws, it can be secured at any position along the linear dovetail surface of the microscope main body bracket. The CA2 coaxial arm has SM2 female threads and four M3 threaded holes for 60 mm coaxial systems. To offer additional mounting configurations, the four M4×6 socket head cap screws can be removed to separate the 95 mm dovetail clamp from the plate with the optical port. This 12.7 mm thick plate can be connected to a 25.4 mm thick dovetail clamp, aligning the plate's surface with either the top or bottom of the clamp. This flexibility allows the coaxial arm to be installed in the most space-efficient manner while keeping the set screws of the dovetail clamp on the same side as the microscope main body bracket. Included alignment pins ensure proper positioning of the plate relative to the dovetail.

Product Model | Thread hole specifications | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| CA1 | SM1 | $235.73 | today | Add Cart | ||

| CA2 | SM2 | $255.21 | today | Add Cart |

- Bottom with male dovetail block for connecting to the microscope main body bracket

- Surface M6 threaded through-hole with threaded hole spacing of 25 mm

- Includes 4 foot blocks to provide support for the breadboard

The LBTEK Top Breadboard undergoes an oxidation blackening treatment, allowing system developers to construct custom wide-field observation setups and epi-illumination pathways on the top of an upright microscope. Each breadboard features a Ø38.1 mm through-hole, with the hole center located on the male dovetail block. This dovetail block enables direct connection of the breadboard to the epi-illumination arm of the microscope main body bracket, or can be used to stack breadboards on top of the epi-illumination module. Additionally, there are 8 M3 threaded holes near the Ø38.1 mm through-hole, designed for 30 mm and 60 mm coaxial systems. The purchase includes 4 M4×12 cylindrical head hex socket screws.

Product Model | Breadboard size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| TBB45 | 450.0 mm x 116.8 mm×12.7 mm | $448.83 | today | Add Cart | ||

| TBB35 | 350.0 mm x 275.0 mm×12.7 mm | $466.88 | today | Add Cart |

Product Model | Material | Compatible Optics Specifications | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| TBB25-T-P New | 6061-T6 aluminum alloy | 26 mm×38 mm×1 mm | $47.72 | today | Add Cart | ||

| TBB25-T New | 6061-T6 aluminum alloy | 35 mm×52 mm×3 mm、25 mm×36 mm×1 mm | $3,500.33 | today | Add Cart |

Product Model | Installation Method | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| MRF1 New | Male and female head dovetail stacking installation | $314.69 | today | Add Cart |

- Provides manual focusing within a 25.4 mm travel range

- 95 mm dovetail clamp on the back for connection to the microscope main body stand

- Includes 6 M3 threaded holes for mounting connecting arms

- Aligns the connecting arm at the optical path 196.5 mm from the edge of the microscope imaging system guide rail

- Adjusts the displacement stage using a knob

The LBTEK Manual Focusing Mount provides a 25.4 mm manual travel range for installed condensers and their mounting brackets. The focusing mount includes a 95 mm dovetail clamp that can attach to the microscope body stand, a manual translation stage, and a mounting bracket with six M3 threaded holes. These six M3 threaded holes are compatible with the M3 countersunk holes on the DMA. When installing the DMA on the manual focusing mount, the optical port aligns with the optical path at a distance of 196.5 mm from the edge of the microscope imaging system rail. The translation stage can be adjusted using the knob. Compared to translation stages with rollers, the manual focusing mount utilizes a dovetail movement mechanism to minimize long-term drift.

Product Model | Arm connection position | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| MFR-B New | Top, Bottom | $847.20 | 6 weeks | Add Cart | ||

| MFR-A | middle | $881.20 | today | Add Cart |

- The mounting bracket allows for the installation of a single objective lens into the DIY microscopic imaging component system.

- Mounting bracket objective lens mounting hole size: M32 x 0.75 internal thread, 4 M3 threaded holes compatible with 60 mm same system.

- The mounting bracket can be installed on a manual focusing stage.

The LBTEK single objective mounting bracket allows for the installation of a single objective lens in the optical path at a distance of 196.59 mm from the main support structure. It is designed to directly accommodate objective lenses with an M32 x 0.75 external thread. Alternatively, our microscope adapters can be used to convert the M32 x 0.75 thread to other industry-standard objective lens threads, such as M26 x 0.706, RMS thread, and others.

With a thickness of only 9.5 mm, the mounting bracket maximizes available space in the Z-direction, facilitating the installation of other microscope modules. It features four M3 threaded holes compatible with a 60 mm coaxial system. Additionally, six M4 countersunk holes on the bracket enable easy mounting onto manual focusing stages (sold separately by our company). The magnet on the upper part of the bracket is used to attach the light-blocking bellows to the main support structure with an epi-illumination arm, creating a light-tight optical path between the bracket and the epi-illumination arm to prevent interference from external light.

Application Example

Product Model | Mounting hole type | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| SOF1 | M32 x 0.75 Thread | $102.63 | today | Add Cart |

- The mounting bracket allows for the installation of a single objective lens into a DIY microscopic imaging component system.

- Mounting bracket objective lens mounting hole size: M32 x 0.75 internal thread, 4 M3 threaded holes compatible with 60 mm same system, with a detachable magnetic objective lens mount.

- The detachable magnetic objective lens mount is available for separate purchase from our company (model: SOFA-A).

- The mounting bracket can be installed on a manual focusing rack.

LBTEK Adjustable Mount can install a single objective lens in the optical path at a distance of 196.59 mm from the main bracket. The mount consists of one mounting arm and one detachable magnetic objective lens mount, allowing users to quickly switch objective lenses without disassembling the entire mount. The ball + V-groove design on the mounting arm and the detachable magnetic objective lens mount provides dynamic positioning functionality, enabling sliding in and out for quick replacement of the objective lens mount, with a repeat positioning accuracy of < ±10 µm in the X and Y axes. The mount has a thickness of only 12.7 mm, maximizing space in the Z-direction to facilitate the installation of other microscopy modules. Four M3 threaded holes are compatible with a 60 mm coaxial system. Six M4 countersunk holes on the mount allow for easy installation onto a manual focusing mount (sold separately by our company).

The detachable magnetic objective lens mount (SOFA-A) can directly accommodate objective lenses with an M32 x 0.75 external thread. Alternatively, our company's microscope adapters can be used to convert the M32 x 0.75 thread to other industry-standard objective lens threads, such as M26X0.706, RMS thread, etc. Four M3 threaded holes on the mount allow for the construction of a detachable 60 mm coaxial assembly. The magnet on the upper part of the mount is used to attach the light-blocking bellows on the main bracket with an epi-illumination arm, forming a light-tight optical path between the mount and the epi-illumination arm to prevent interference from external light.

-Fr3zHvWPpoPtThrKRVnGNWLE2Jer.jpg)

Application Example

Product Model | Mounting hole type | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| SOFA-A | M32 x 0.75 Thread | $90.73 | today | Add Cart | ||

| SOFA | M32 x 0.75 Thread | $228.01 | Contact | Add Cart |

- For conversion between mounting threads of objectives such as RMS, M26, M32, M25, etc.

LBTEK objective adapters include threaded adapters with internal and external thread specifications such as M26×0.706 and M32×0.75 threads. The surface is black anodized to reduce stray light reflection. LBTEK continuously introduces new adapters; please refer to the technical specifications. In addition to standard threaded adapters, LBTEK also offers custom adapter services for special-sized thread specifications. If needed, please contact LBTEK technical support.

Application Example

Product Model | Material | Surface treatment | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| M32-m26 | 6061-T6 Aluminum Alloy | Black anodized | $20.13 | Contact | Add Cart | ||

| M25A-M32B | 6061-T6 Aluminum Alloy | Black anodized | $20.13 | today | Add Cart | ||

| RMS-M32B | 6061-T6 Aluminum Alloy | Black anodized | $20.13 | today | Add Cart |

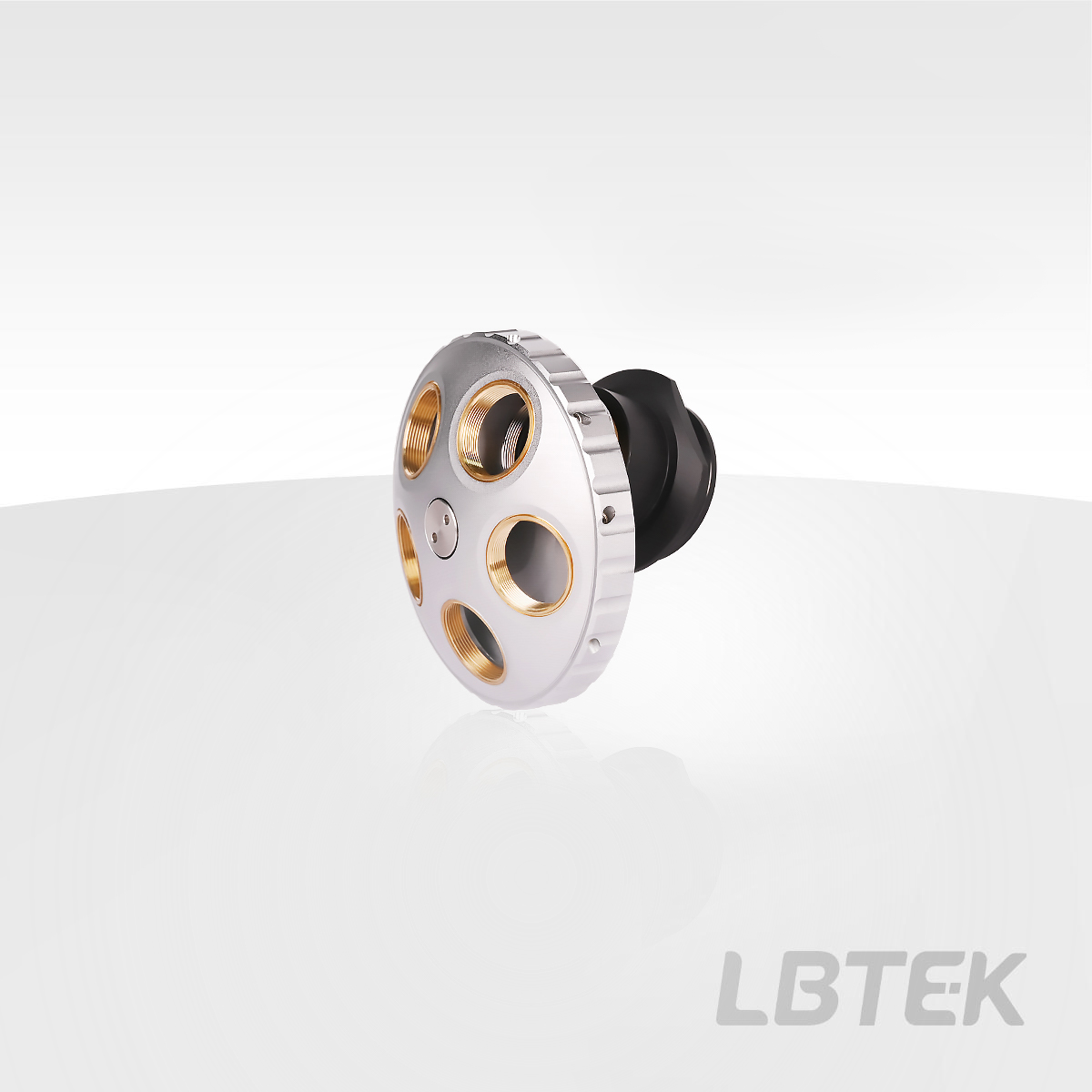

- Rotatable to switch between five objectives

- Upper mechanical interface Φ38.1mm D1T male dovetail

- Lower end with five RMS internal threads for mounting objectives

The objective lens mounting frame allows for the installation of five objective lenses in a self-assembled microscopic system, facilitating the construction of systems that require switching between multiple high and low magnification objective lenses. The housing and threads of the objective lens mounting frame are made of copper, with a stainless steel backplate at the top. The combination of a spring plate and a hard stainless steel ball, along with the positioning grooves on the housing, forms a precise positioning mechanism. This positioning mechanism can secure the objective lens, ensuring an objective lens switching positioning accuracy of ≤±50 μm and a single-hole bidirectional repeatability of ≤30 μm. It ensures that the optical components in the system are aligned with the optical axis both vertically and horizontally. The five objective lens mounting threads at the lower end of the FOF1 are RMS threads. The upper end of the objective lens mounting frame features a D1T male dovetail, which can be mounted onto a manual focusing stage using a DMAS mounting arm (sold separately).

Application Example

Product Model | Material | Surface treatment | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| FOF1 New | 6061-T6 aluminum alloy | Black anodized | $829.81 | 5 weeks | Add Cart |

- Installing two objectives in the experimental system

- Two M32×0.75 internal threads included

- Manual switching

The LBTEK Dual-Objective Nosepiece is constructed from 6061-T6 aluminum alloy for high precision and excellent rigidity. It features two M32 x 0.75 threaded holes with a center distance of 63.5 mm, accommodating objectives of varying magnifications. For objectives with other thread sizes, LBTEK thread adapters are available, or you may contact technical support for custom installations.

The Dual-Objective Nosepiece is typically equipped with two objectives of different magnifications.

Product Model | Thread specification | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| DMA | M3 | $162.90 | today | Add Cart | ||

| DOF | M32×0.75 | $1,236.94 | today | Add Cart |

- The objective mounting hole on the mounting arm is a φ38.2 mm female dovetail

- The objective mounting hole on the mounting arm is compatible with five-objective mounting brackets, dual-objective mounting brackets, and single-objective mounting (requires a dovetail adapter for use)

LBTEK mounting arm, used to install the objective lens mount onto a manual focusing stage. The objective lens mounting hole on the arm features a φ38.2 mm female dovetail, compatible with five-objective lens mounts, dual-objective lens mounts, and single-objective lens mounts (requires a dovetail adapter for use). The magnet on the upper part of the mounting arm is used to attach the light-blocking bellows on the main bracket with epi-illumination arm, forming a light-tight optical path between the mounting arm and the epi-illumination arm to prevent interference from external light.

Application Example

Product Model | Mounting hole type | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| DMAS | 38.2 mm Female Dovetail | $156.63 | today | Add Cart |

- The mounting platform features M6 threaded holes for arrays, facilitating user DIY of microscopic imaging components and expansion mounting of optomechanical parts.

- The mounting platform can slide and be fixed in position on the main bracket.

- Snap-in rail brackets can be installed and removed at any position on the main bracket.

- The rail plate can only be installed from the end face of the main bracket and can be moved and fixed in position on the main bracket.

The LBTEK mounting platform allows DIY microscopic imaging component modules to be mounted onto the main frame. The mounting platform features an array of M6 threaded holes for installing various optomechanical components.

The snap-in rail bracket can be secured to the main frame by tightening the side M6 screws. When the side M6 screws are loosened, the hinged dovetail clamp can self-open with the assistance of an auxiliary mechanism. As the screws are loosened further, a gap will appear between the dovetail clamp and the main frame, allowing the rail bracket to be installed or removed at any position on the main frame. Alternatively, slightly loosening the side M6 screws enables the rail bracket to slide along the main frame. Tightening the side M6 screws again will secure it at a new position on the main frame.

The rail plate is equipped with an array of 17 M6 threaded holes and 4 M6 countersunk holes. Tightening the four included M6 screws secures the rail plate to the main frame. Beneath these four M6 screws are two T-nut-like components that can be inserted from the end face of the main frame. Therefore, installing the rail plate on the main frame requires the top plate of the main frame to be detachable. For this reason, it is only recommended to install the rail plate on a main frame without an epi-illumination arm. If installed on a main frame with an epi-illumination arm, disassembling the epi-arm may affect the realignment accuracy of the optical path, and such usage is not advised.

Note: If both a rail bracket and a rail plate are installed on the same main frame, the distance between the surface with the array of M6 threaded holes and the main frame will differ by 7.5mm.

Application Example

Product Model | Installation Method | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| AP95F-81B | Insert at the end of the 95mm guide rail, allowing sliding along the rail. | $35.04 | today | Add Cart | ||

| AP95F-100A | Can be inserted or removed at any position on the 95mm rail. | $98.06 | today | Add Cart |

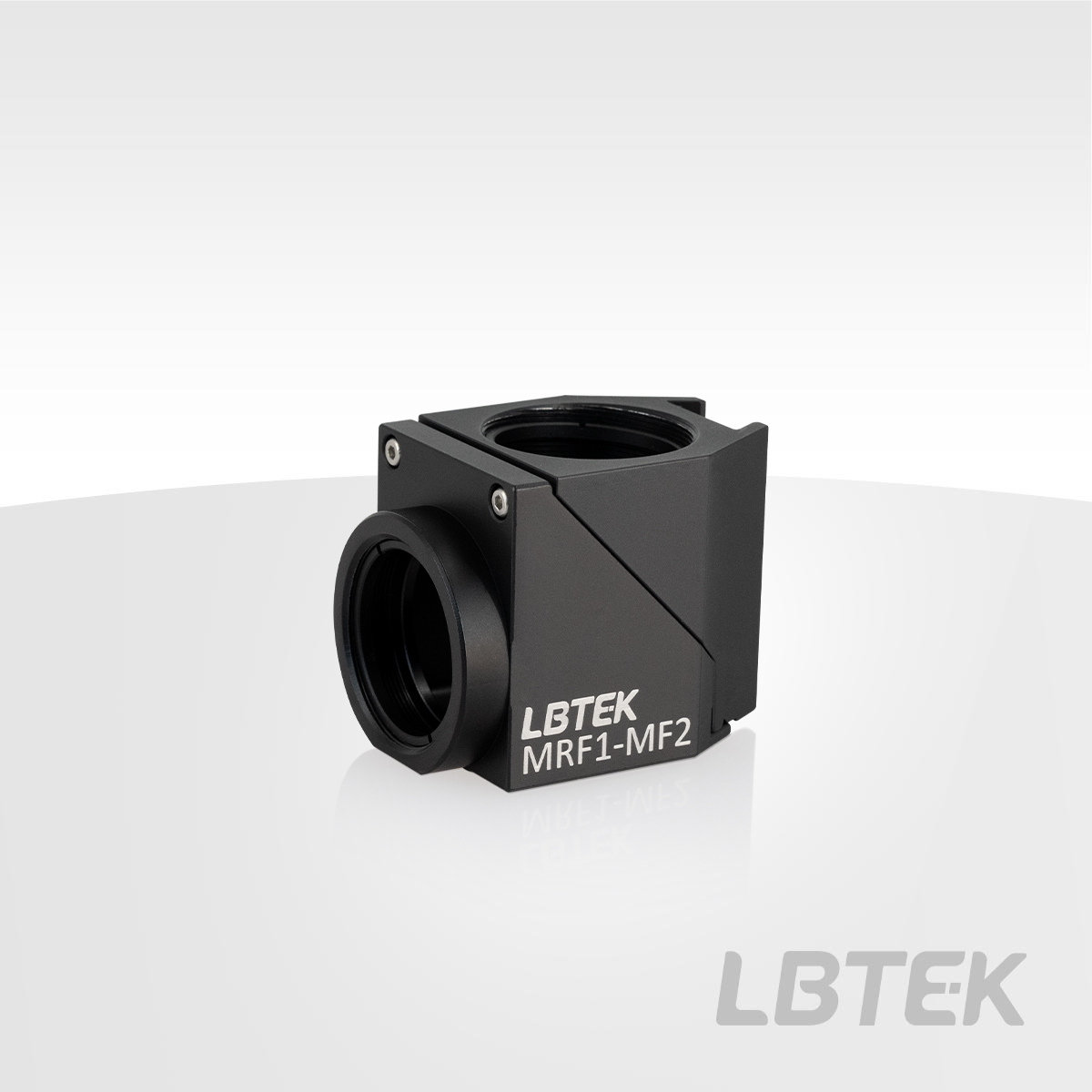

- The filter cube comes with a dovetail slot for installation in a single-port epi-illumination module

- It can accommodate one rectangular dichroic mirror (36.0 mm × 25.0 mm × 1.0 mm) + one circular excitation filter (Ø25 mm, maximum thickness 5 mm) + one circular emission filter (Ø25 mm, maximum thickness 3.5 mm), forming a complete fluorescence filter cube set.

The LBTEK filter cube comes with a dovetail mounting slot, which can be installed on the dovetail block of the front door cover of a single-port epi-illumination box. The filter cube can accommodate one 36.0 mm × 25.0 mm × 1.0 mm dichroic mirror (maximum compatible size is 36.0 mm × 25.2 mm × 1.0 mm). Two SM1 threaded holes can secure one excitation filter (Ø25 mm, maximum thickness 5 mm) and one emission filter (Ø25 mm, maximum thickness 3.5 mm) using retaining rings, allowing it to form a complete fluorescence filter cube set.

Application Example

Product Model | Compatible Optics Specifications | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| MRF1-MF2 New | 1 piece 36mm×25mm×1mm / 2 pieces Ø25mm | $235.33 | today | Add Cart |

- The dovetail adapter includes dovetail adapters of various male and female dovetail specifications such as D1N.

BTEK Dovetail Adapters include various male and female dovetail specifications such as DIN. The surface is black anodized to reduce stray light reflection. LBTEK continuously introduces new adapters. Please refer to the technical specifications. In addition to standard dovetail adapters, LBTEK also provides custom adapter services for special-sized dovetail specifications. If needed, please contact LBTEK technical support.

Application Example

Product Model | Material | Surface treatment | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| SM2-D1N | 6061-T6 Aluminum Alloy | Black anodized | $31.90 | today | Add Cart |