Specifications

Curve

Tutorial

Assembly

Feedback

Product Description

- Optical Material: Borofloat Glass, H-K9L, UVFS

- Silicon Dioxide Protective Layer

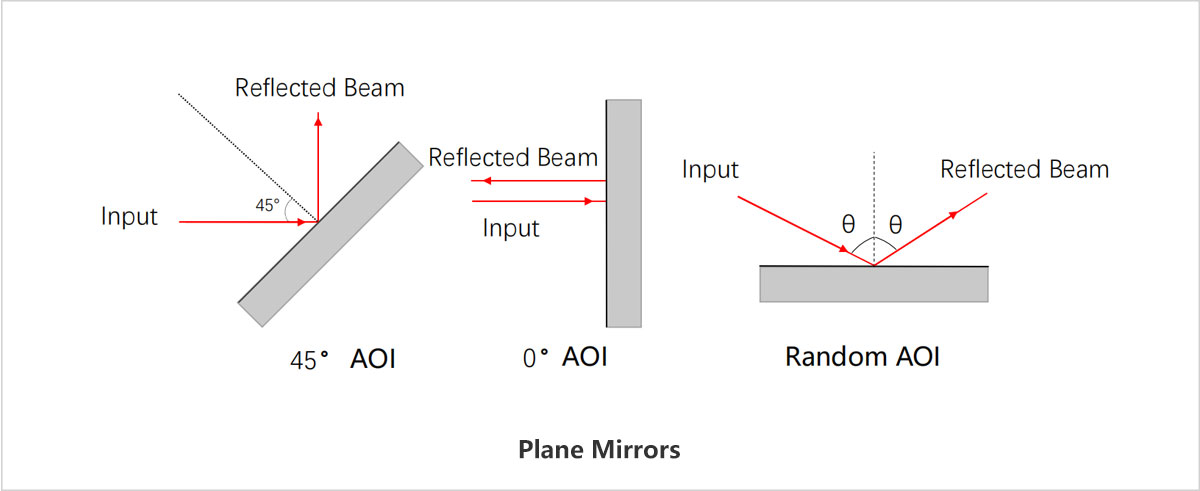

- Application: Optical Path Deflection

- Working Wavelength: 480 nm-20 μm

Metal-coated mirrors are highly suitable for deflecting light paths of broadband light sources, offering high reflectivity across a wide spectral range. However, metal coatings are prone to oxidation, discoloration, or peeling in high-humidity environments. LBTEK's metal-coated mirrors feature a protective layer of silicon dioxide on the surface to isolate the metal coating from direct contact with air. Although the protective layer prevents silver oxidation, silver-coated mirrors still cannot be used in high-humidity environments and must be operated and stored in low-humidity, room-temperature conditions.

LBTEK offers three types of metal-coated mirrors: aluminum-coated, silver-coated, and gold-coated. All our mirrors undergo precision manufacturing and strict quality control to ensure LBTEK provides high-quality mirror products at reasonable prices. For customized metal-coated mirrors, please contact LBTEK Technical Support.

Diagram

Attributes

Optical component materialBorofloat glass, H-K9L, UVFS

Clear Aperture90% CA

Operating Wavelength480 nm-20.0 μm

ReflectivityRavg>96%

Metal Plane Mirrors, Silver Coating: 480 nm-20.0 μm, Circular

- Substrate Material: Borofloat Glass, H-K9L

- Silicon Dioxide Protective Layer

- Application: Optical Path Deflection

- Operating Wavelength: 480 nm-20.0 μm (Silver Coating)

LBTEK offers Ø12.7 mm, Ø25.4 mm, and Ø50.8 mm silver-coated metal plane mirrors. Metal-coated mirrors are highly suitable for deflecting light paths of broadband light sources, as they provide high reflectivity across a wide spectral range. Metal coatings are prone to oxidation, discoloration, or peeling in high-humidity environments. LBTEK's metal-coated mirrors feature a layer of silicon dioxide protective coating on the surface to isolate the metal coating from direct contact with air. Although the protective layer can prevent silver oxidation, silver-coated mirrors still cannot be used in high-humidity environments and must be operated and stored in room-temperature conditions with minimal humidity. When using silver-coated mirrors, it is recommended to wear latex gloves or finger cots to prevent contamination of the optical surface by residual oils or other substances from fingers. Handle with care during use, avoiding contact with the mirror surface and edges.

LBTEK Silver Coated Mirror mounted on standard Ø1" two-axis optical mount AMM-1B

Product Model | Diameter | Thickness | Optical component material | Package Quantity | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| PM20-T08-AG-SP | 50.8 mm | 8.0 mm | H-K9L | 1 | $78.84 | today | Add Cart | ||

| PM05T-AG | 12.7 mm | 6.0 mm | Borofloat 33 | 1 | $28.76 | today | Add Cart | ||

| PM10-AG-P10 | 25.4 mm | 6.0 mm | Borofloat 33 | 10 | $430.66 | today | Add Cart | ||

| PM10-AG | 25.4 mm | 6.0 mm | Borofloat 33 | 1 | $48.24 | today | Add Cart | ||

| PM20-AG | 50.8 mm | 12.7 mm | Borofloat 33 | 1 | $101.32 | today | Add Cart | ||

| PM05-AG | 12.7 mm | 3.1 mm | Borofloat 33 | 1 | $29.02 | today | Add Cart |

Metal Plane Mirrors, Silver Coating: 480 nm-20.0 μm, Economy Type

- Economy

- 480 nm - 20 µm

- Ø1/2 inch, Ø1 inch and Ø2 inch Optional

Economical silver-coated mirrors are available in Ø1/2 inch, Ø1 inch, and Ø2 inch options. The silver coating provides high reflectivity from 480 nm to 20 µm. LBTEK silver-coated mirrors feature an SiO2 protective layer to prevent oxidation and damage to the coating. Although the protective layer can prevent silver oxidation, silver-coated mirrors still cannot be used in high-humidity environments and must be used and stored in room-temperature conditions with minimal humidity. When handling silver-coated mirrors, it is recommended to wear latex gloves or finger cots to prevent contamination of the optical surface by residual oils and other substances from fingers. Handle with care, avoiding contact with the mirror surface and edges. Compared to standard silver-coated mirrors, economical silver-coated mirrors have lower surface quality but are more cost-effective.

LBTEK Silver Coated Mirror mounted on standard Ø1" two-axis optical mount AMM-1B

Product Model | Optical component material | Diameter | Thickness | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| EPM20-AG | Borofloat 33 | 50.8 mm | 3.2 mm | $54.26 | today | Add Cart | ||

| EPM05-AG | Borofloat 33 | 12.7 mm | 3.2 mm | $19.48 | today | Add Cart | ||

| EPM10-AG | Borofloat 33 | 25.4 mm | 3.2 mm | $31.51 | today | Add Cart |

Elliptical Reflectors, Silver-coated: 480 nm - 20.0 μm

- Base Material: UV Fused Silica

- Silicon Dioxide Protective Coating

- Application: Beam Deflection

- Operating Wavelength: 480 nm-20.0 μm

LBTEK offers elliptical silver-coated metal plane mirrors with a major axis of 35.9 mm and a minor axis of 25.4 mm. Metal-coated mirrors are highly suitable for deflecting light paths of broadband light sources, as they exhibit high reflectivity across a wide spectral range. Metal coatings are prone to oxidation, discoloration, or peeling in high-humidity environments. To prevent direct contact between the metal coating and air, LBTEK's metal-coated mirrors are coated with a layer of silicon dioxide protective film. Although the protective layer can prevent silver oxidation, silver-coated mirrors should still not be used in high-humidity environments. They must be used and stored in room-temperature conditions with minimal humidity. When handling silver-coated mirrors, it is recommended to wear latex gloves or finger cots to prevent contamination of the optical surface by oils or residues from fingers. Handle with care, avoiding contact with the mirror surface and edges.

LBTEK Silver-Coated Elliptical Mirror Mounted on 45 Degree Adjustable Mount

Product Model | Optical component material | Size | Operating Wavelength | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| PM05E-AG | UV fused silica | Ellipse: Major axis: 18.0 mm (reference value) Minor axis: 12.7 mm | 480 nm-20.0 μm | $51.90 | today | Add Cart | ||

| PM10E-AG | UV fused silica | Ellipse: Major axis: 35.9 mm Minor axis: 25.4 mm | 480 nm-20.0 μm | $79.23 | 8 weeks | Add Cart |

Metal-coated Flat Mirrors, Silver Film: 480 nm-20.0 μm, D-shaped

- Substrate Material: UVFS

- Silica Protective Layer

- Purpose: Beam Splitting

LBTEK offers D-shaped silver-coated mirrors with high reflectivity across a broad spectrum, suitable for selecting one beam from two closely spaced beams. Additionally, the straight edge of the mirror has a wedge-shaped bevel at a 45° angle on the backside, facilitating beam splitting for diverging or converging beams.

Metal coatings are prone to oxidation, discoloration, or peeling in high-humidity environments. LBTEK's metal-coated mirrors feature a protective silicon dioxide (SiO₂) layer on the surface to prevent direct contact between the metal coating and air. Although the protective layer helps prevent silver oxidation, silver-coated mirrors should not be used in high-humidity conditions and must be stored and operated in low-humidity, room-temperature environments.

When handling silver-coated mirrors, it is recommended to wear latex gloves or finger cots to prevent contamination from fingerprints, oils, or other residues on the optical surface. Exercise caution during use, avoiding direct contact with the mirror surface or edges.

The D-type mirror is mounted on the D-type mirror mount AMM-1DL.

Product Model | Optical component material | Diameter | Thickness | Clear Aperture | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| PM10D-AG | UV fused silica | 25.4 mm | 6.0 mm | 90% CA | $60.27 | today | Add Cart |

Metal Plane Mirrors, Silver Coating: 480 nm-20.0 μm, Rectangular

- Substrate Material: Borofloat Glass

- Working Wavelength: 480 nm-20.0 μm (Silver Coating)

- Silicon Dioxide Protective Layer

- Application: Optical Path Deflection

LBTEK offers rectangular silver-coated metal plane mirrors. Metal-coated mirrors are highly suitable for deflecting light paths of broadband light sources, as they provide high reflectivity across a wide spectral range. Metal coatings are prone to oxidation, discoloration, or peeling in high-humidity environments. LBTEK's metal-coated mirrors feature a layer of silicon dioxide protective coating on the surface to isolate the metal coating from direct contact with air. Although the protective layer can prevent silver oxidation, silver-coated mirrors still cannot be used in high-humidity environments. They must be used and stored in room-temperature conditions with minimal humidity. When handling silver-coated mirrors, it is recommended to wear latex gloves or finger cots to prevent contamination of the optical surface by residual oils or other substances from fingers. Handle with care, avoiding contact with the mirror surface and edges.

LBTEK Square Silver-Coated Mirror Mounted on Rectangular Precision Optical Mount AMM3-1SL

Product Model | Optical component material | Size | Thickness | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| PMR10-AG | Borofloat 33 | 25.0 mm×36.0 mm | 1.0 mm | $78.97 | today | Add Cart | ||

| PMS10-AG | Borofloat 33 | 25.4 mm×25.4 mm | 6.0 mm | $51.77 | today | Add Cart | ||

| PMS05-AG | Borofloat 33 | 12.7 mm×12.7 mm | 3.1 mm | $31.25 | 6 weeks | Add Cart |