- Optical Material: Borofloat Glass, UVFS

- Silicon Dioxide Protective Layer

- Working Wavelength: 250 nm-600 nm, 250 nm-450 nm

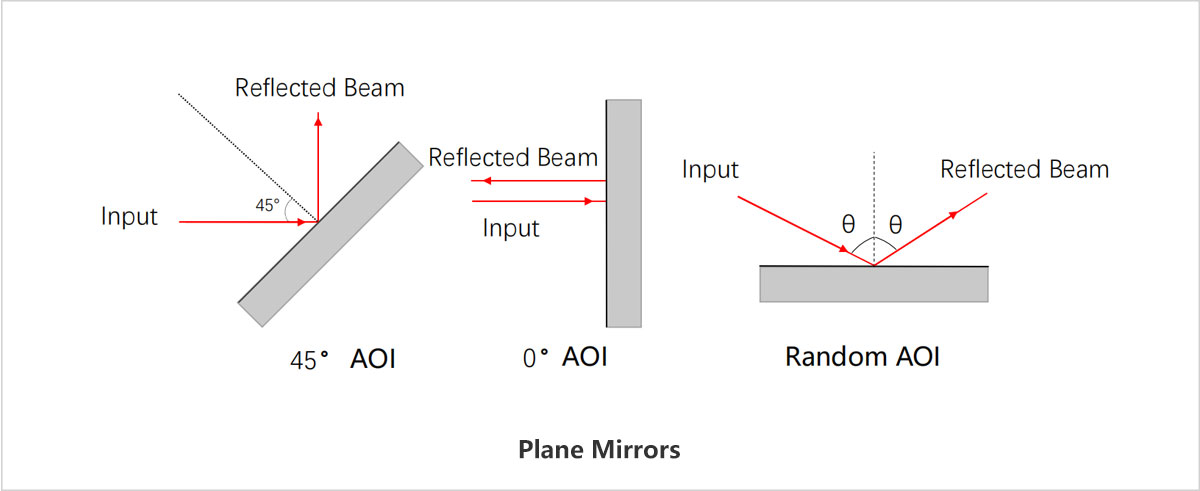

- Application: Optical Path Deflection, Beam Splitting

- Substrate Material: Borofloat Glass, UVFS

- Silicon Dioxide Protective Layer

- Operating Wavelength: 250 nm-600 nm

- Application: Optical Path Deflection

LBTEK offers UV-enhanced aluminum-coated flat mirrors, which are highly suitable for beam deflection in the ultraviolet spectral range, featuring high reflectivity across a broad spectrum. The reflection of the beam on the metal-coated surface does not introduce chromatic aberration. Metal coatings are prone to oxidation, discoloration, or peeling in high-humidity environments. LBTEK's metal-coated mirrors are coated with a layer of silicon dioxide protective film on the surface to isolate the metal coating from direct contact with air, preventing oxidation and preserving optical performance.

LBTEK circular mirrors are mounted in standard O-type optical mounts

Product Model | Diameter | Thickness | Optical component material | Operating Wavelength | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| PM05-UVAL-SP | 12.7 mm | 3.1 mm | UVFS | 250 nm-600 nm | $70.34 | today | Add Cart | ||

| PM10-UVAL-P10 | 25.4 mm | 6.0 mm | Borofloat 33 | 250 nm-600 nm | $439.03 | today | Add Cart | ||

| PM10-UVAL | 25.4 mm | 6.0 mm | Borofloat 33 | 250 nm-600 nm | $48.37 | today | Add Cart | ||

| PM20-UVAL | 50.8 mm | 12.7 mm | Borofloat 33 | 250 nm-600 nm | $98.45 | today | Add Cart | ||

| PM05-UVAL | 12.7 mm | 3.1 mm | Borofloat 33 | 250 nm-600 nm | $30.59 | today | Add Cart |

- Substrate Material: UVFS

- Silicon Dioxide Protective Coating

- Operating Wavelength: 250 nm-600 nm

- Dimensions: Elliptical, Minor Axis 12.7 mm or Minor Axis 25.4 mm

LBTEK elliptical mirror mounted in a 45-degree elliptical mount

Product Model | Optical component material | Size | Thickness | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| PM05E-UVAL | UV fused silica | Ellipse: Major axis: 18.0 mm (reference value) Minor axis: 12.7 mm | 6.0 mm | $102.24 | today | Add Cart | ||

| PM10E-UVAL | UV fused silica | Ellipse: Major axis: 35.9 mm (reference value) Minor axis: 25.4 mm | 6.0 mm | $141.85 | today | Add Cart |

- Substrate Material: UVFS

- Operating Wavelength: 250 nm-450 nm

- Application: Beam Splitting

LBTEK D-type mirror is mounted in a D-type optical mount

Product Model | Diameter | Thickness | Optical component material | Operating Wavelength | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| PM10D-UVAL | 25.4 mm | 6.0 mm | UVFS | 250 nm-450 nm | $55.83 | 7 weeks | Add Cart |

- Substrate Material: Borofloat Glass

- Economy Type

- Available in Ø1/2 inch, Ø1 inch, and Ø2 inch

LBTEK offers cost-effective UV-enhanced aluminum-coated flat mirrors suitable for beam deflection in the ultraviolet spectral range, featuring high reflectivity across a broad spectrum. The beam reflects off the metal coating surface without introducing chromatic aberration. Since metal coatings are prone to oxidation, discoloration, or peeling in high-humidity environments, LBTEK's metal-coated mirrors are protected with a layer of silicon dioxide to isolate the metal coating from direct contact with air, preventing oxidation and preserving optical performance. Compared to standard UV-enhanced aluminum-coated mirrors, the cost-effective version has relatively inferior surface quality and reflectivity but comes at a lower price.

LBTEK circular mirrors are mounted in standard O-type optical mounts

Product Model | Diameter | Thickness | Optical component material | Operating Wavelength | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| EPM05P-UVAL | 12.7 mm | 3.0 mm | Borofloat 33 | 250 nm-600 nm | $19.22 | today | Add Cart | ||

| EPM10P-UVAL | 25.4 mm | 6.0 mm | Borofloat 33 | 250 nm-600 nm | $31.12 | today | Add Cart | ||

| EPM20P-UVAL | 50.8 mm | 12.7 mm | Borofloat 33 | 250 nm-600 nm | $53.60 | today | Add Cart |