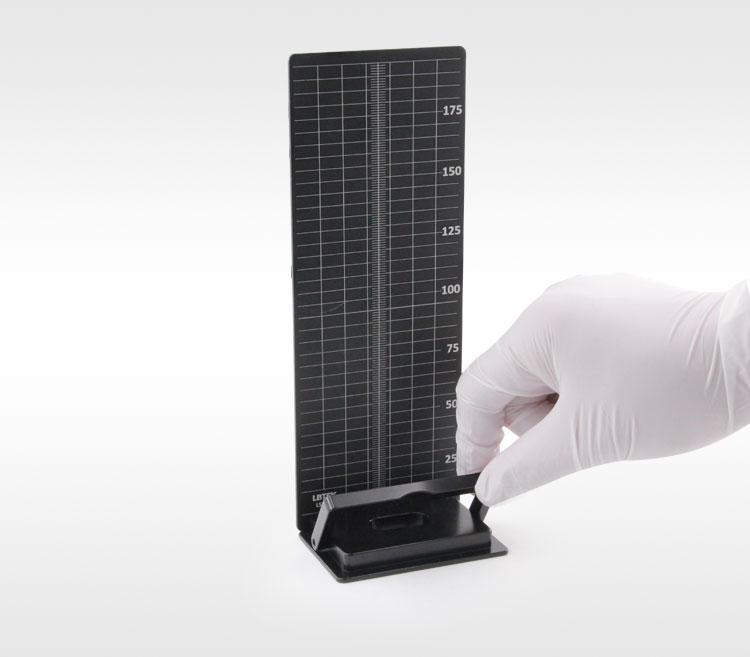

- Magnetic base with pre-fixed adsorption force available

- Double-sided with height scale lines

- Slotted countersunk hole for M6 socket head cap screw

- High graduation resolution: 5 mm at edges, 1 mm in center

- Two bottom magnets Ø15×2.5 mm

- Compatible with M6 hex socket head cap screws

- With lifting handle

The LSSM1 measures 200 mm × 75 mm, and the LSSM2 measures 305 mm × 75 mm. Both sides feature height marking lines, with edge scale graduations at 5 mm resolution and center scale graduations at 1 mm resolution. They can be used to determine the height position of laser spots. The base is equipped with two Ø15×2.5 mm magnets and an M6 countersunk waist-shaped hole, allowing fixation using an M6 hex socket head cap screw. This enables secure mounting on non-magnetic platforms. The entire surface undergoes shot-blasted black anodization, which helps block stray or unwanted light beams and creates a uniform scattering surface. Additionally, the base includes a retractable handle for easy lifting of the plates from magnetic platforms.

Lifting handle for laser safety shield Plates

Product Model | Size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| LSSM2 | 305 mm×75 mm | $37.39 | today | Add Cart | ||

| LSSM1 | 200 mm×75 mm | $34.78 | today | Add Cart |