- V-clamps or baseplate clamps

- Commonly used for clamping cylindrical or rectangular optical and mechanical components

- The clamping arm of the V-clamps can be swapped left and right

- The screws of the baseplate clamp can adjust the spacing arbitrarily according to the bottom M6 threaded hole positions

- Commonly used for clamping cylindrical optical or mechanical components

- Left-right interchangeable clamping arm design

- M4 or M6 threaded holes at the base

The LBTEK V-Clamp is commonly used for cylindrical optical or mechanical components. The V-clamps HM-V25, HM-V50, and HM-V76 can hold cylinders with diameters ranging from 3 mm to 25 mm, 10 mm to 50 mm, and 12.5 mm to 76.5 mm, respectively. Among them, HM-V50 and HM-V76 can also be equipped with multiple sets of clamping arms simultaneously to enhance clamping stability. Additionally, the arms of both V-type clamps can be swapped left and right. The rear, left, right sides, and bottom of the V-block feature M4 or M6 threaded holes, allowing installation on standard optomechanical components.

The LBTEK V-Clamp Installation

Product Model | Clamping diameter | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| HM-V76 | 12.5 mm~76.5 mm | $94.40 | today | Add Cart | ||

| HM-V50 | 10 mm~50 mm | $37.65 | today | Add Cart | ||

| HM-V25 | 3 mm~25 mm | $35.17 | today | Add Cart |

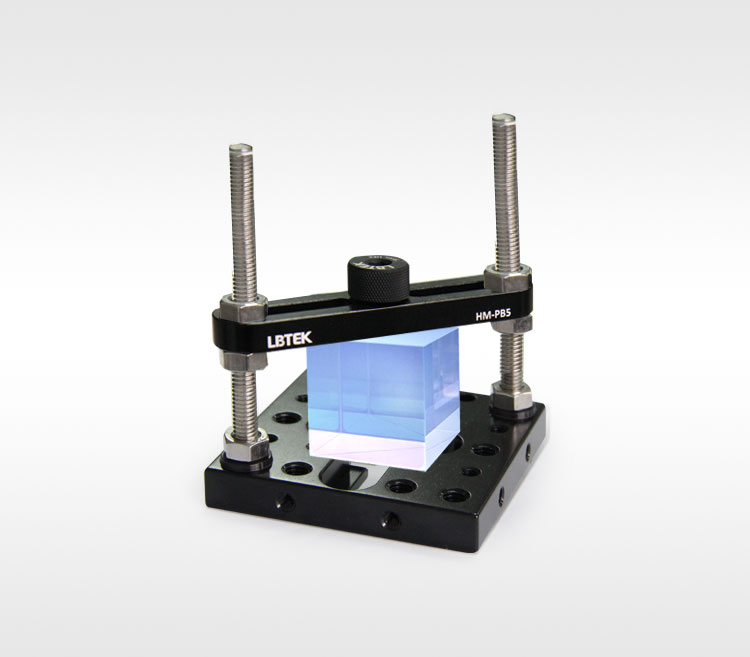

- Commonly used for clamping rectangular optical or mechanical components

- The screw can adjust the spacing arbitrarily according to the bottom M6 threaded hole position

- The bottom has M4 or M6 threaded holes

- Comes with a 10 mm wrench for tightening screws and baseplates

The LBTEK HM-PB5 baseplate clamp is commonly used for clamping rectangular optical or mechanical components. The clamping height can be adjusted by turning the hex nut, with an unlimited clamping length range, a width range of 0–58 mm, and a height range of 0–65 mm. The U-groove design of the clamping plate allows the screw to adjust the spacing freely according to the bottom M6 threaded hole positions. The clamping plate is equipped with a spring-loaded knurled hex thumb screw at the center to ensure the clamped surface remains undamaged. The base plate features M6 slots, M4 or M6 threaded holes, allowing installation on standard optomechanical components such as breadboards or bases. A 10 mm wrench is included for tightening the screws and base plate.

LBTEK baseplate clamps are commonly used for clamping large-sized optical or mechanical components.

Product Model | Clamping size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| HM-PB5 | 58 mm×65 mm | $76.75 | today | Add Cart |