Specifications

Application

Feedback

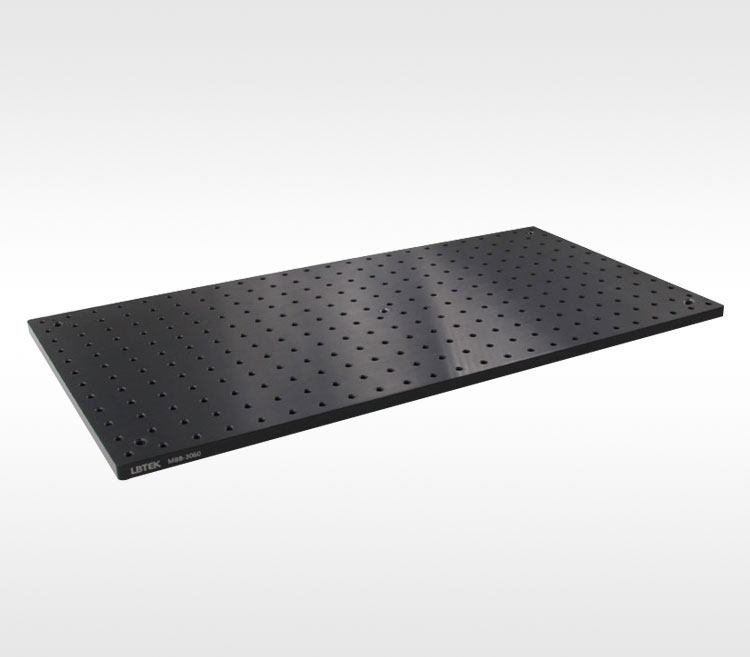

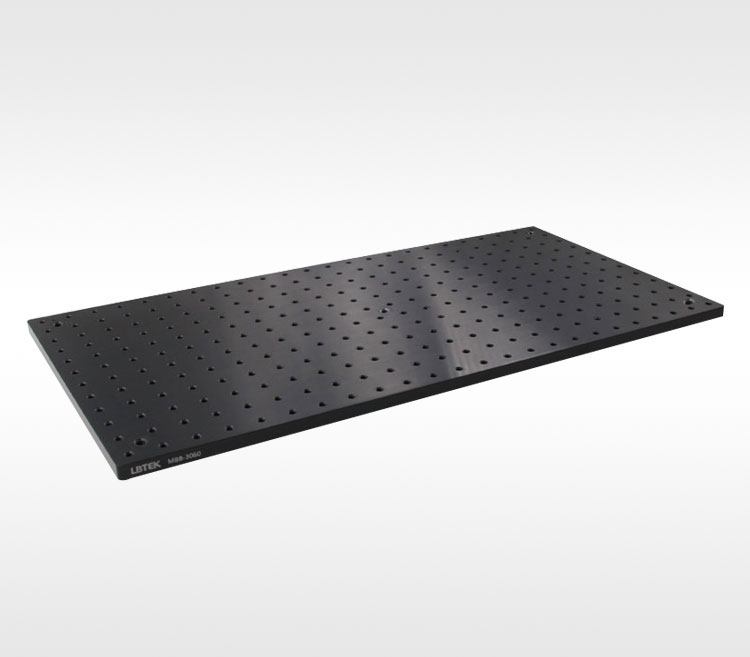

Product Description

- Material: 6061-T6 Aluminum Alloy

- Surface Features M6 Threaded Through-holes with a Hole Pitch of 25 mm

- Breadboards with a Length Greater than 300 mm Have a Total of Five Counterbored Mounting Holes around the Perimeter and at the Center

- Various Sizes and Customerization Available

LBTEK provides standard non-magnetic solid aluminum breadboards, which can be used to build compact optical systems. The surface of the breadboard is black anodized to minimize surface reflections as much as possible, reducing the impact on the optical system. The breadboard features an array of standard M6 threaded through-holes with a hole pitch of 25 mm, allowing customers to mount components from both sides. LBTEK’s optical breadboards with a length greater than 300 mm have a total of five counterbored mounting holes. Four of these counterbored holes are located at the four corners of the breadboard, 25 mm from the edge, and the fifth is positioned at the exact center of the breadboard. These five counterbored mounting holes can be used to install vibration-damping rubber pads or other mounting bases, or the breadboard can be mounted onto the surface of an optical table through these counterbored holes. When there is significant load-bearing at the center of the breadboard, adding a mounting base at the central counterbored hole ensures the rigidity of the breadboard surface and reduces deformation. In addition to standard optical breadboards, LBTEK also offers special surface treatment processes, custom sizes, shapes, or drilling services. For any special requirements, please contact LBTEK customer service.

Diagram

Attributes

Material6061-T6 Aluminum Alloy

Surface treatmentBlack Anodized

Breadboard thickness12.7 mm

Flatness (Full Plane)±0.15 mm

Thread hole sizeM6 Threaded Through-Holes

Thread hole spacing25 mm

Distance from the outermost threaded hole to the edge12.5 mm

Standard Optical Breadboards

- Material: 6061-T6 Aluminum Alloy

- Threaded Holes: M6 Through Holes with a Pitch of 25 mm

- Breadboards with Length ≤300 mm Have Four Countersunk Mounting Holes

- Breadboards with Length >300 mm Have Five Countersunk Mounting Holes

The LBTEK breadboard is manufactured according to national precision standards, with a surface treated by black anodization to minimize surface reflection and reduce its impact on optical systems. The breadboard surface features a standard M6 threaded through-hole array with a hole spacing of 25 mm. For LBTEK optical breadboards longer than 300 mm, five countersunk mounting holes are provided. When the center of the breadboard is under heavy load, adding a mounting base at the central countersunk hole ensures surface rigidity and reduces the effects of deformation.

LBTEK breadboards feature rounded corners on all edges.

Product Model | Material | Breadboard length | Breadboard width | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| MBB-6090 | 6061-T6 Aluminum Alloy | 900 mm | 600 mm | $590.03 | today | Add Cart | ||

| MBB-6060 | 6061-T6 aluminum alloy | 600 mm | 600 mm | $389.35 | today | Add Cart | ||

| MBB-3060 | 6061-T6 Aluminum Alloy | 600 mm | 300 mm | $206.96 | today | Add Cart | ||

| MBB-3045 | 6061-T6 Aluminum Alloy | 450 mm | 300 mm | $169.44 | today | Add Cart | ||

| MBB-3030 | 6061-T6 Aluminum Alloy | 300 mm | 300 mm | $96.62 | today | Add Cart | ||

| MBB-2020 | 6061-T6 Aluminum Alloy | 200 mm | 200 mm | $58.57 | today | Add Cart | ||

| MBB-1530 | 6061-T6 Aluminum Alloy | 300 mm | 150 mm | $70.21 | today | Add Cart | ||

| MBB-1515 | 6061-T6 Aluminum Alloy | 150 mm | 150 mm | $42.75 | today | Add Cart | ||

| MBB-1015 | 6061-T6 Aluminum Alloy | 150 mm | 100 mm | $34.25 | today | Add Cart | ||

| MBB-60120 New | 6061-T6 Aluminum Alloy | 600 mm | 300 mm | $739.47 | today | Add Cart | ||

| MBB-3090 New | 6061-T6 aluminum alloy | 600 mm | 300 mm | $259.00 | today | Add Cart | ||

| MBB-1560 New | 6061-T6 Aluminum Alloy | 600 mm | 300 mm | $121.46 | today | Add Cart | ||

| MBB-1545 New | 6061-T6 Aluminum Alloy | 600 mm | 300 mm | $99.62 | today | Add Cart | ||

| MBB-1030 New | 6061-T6 aluminum alloy | 600 mm | 300 mm | $52.17 | today | Add Cart | ||

| MBB-4560 | 6061-T6 aluminum alloy | 450 mm | 600 mm | $328.42 | today | Add Cart |

Optical Breadboards (Customized for Clients)

- Material: 6061-T6 Aluminum Alloy

- Breadboards Longer Than 300 mm Feature Five Countersunk Mounting Holes

- Customize Products According to Requirements, Other Sizes And Specifications Can Also be Customized

LBTEK offers customized optical breadboards with modifications to overall dimensions and hole positions. Additionally, for special requirements regarding material, unique surface treatment processes, shape, or hole specifications, please contact LBTEK customer service.

Customization options include the following:

Material: Standard product is 6061-T6 aluminum alloy; optional stainless aluminum alloy 5083 with no surface treatment for vacuum environments.

Surface Treatment Process: Standard product features brushed black anodization; optional sandblasted black anodization.

Dimensions/Shape/Hole Spacing/Hole Specifications: Customized according to customer requirements.

Flatness Requirement: ±0.15 mm (within a 1000 mm × 600 mm area; for areas exceeding this range, parameter confirmation is required—please contact customer service).

LBTEK breadboards feature rounded corners on all edges.

Product Model | Material | Breadboard length | Breadboard width | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| MBB-1020-SP | 6061-T6 Aluminum Alloy | 200 mm | 100 mm | $38.83 | today | Add Cart | ||

| MBB-6090-SP | 6061-T6 Aluminum Alloy | 900 mm | 600 mm | Contact | 5 weeks | Add Cart | ||

| MBB-6080-SP | 6061-T6 Aluminum Alloy | 800 mm | 600 mm | Contact | 5 weeks | Add Cart |

Standard Optical Breadboard With Center Through-Holes

- Material: 6061-T6 Aluminum Alloy

- The Breadboard Features a Central Through Hole

- Threaded Holes: M6 Through Holes With A Pitch of 25 mm

The LBTEK breadboard is manufactured according to national precision standards, with a black anodized surface to minimize surface reflection and reduce impact on optical systems. The breadboard features a standard M6 threaded through-hole array with a hole spacing of 25 mm. It includes a central through-hole for laser transmission, cable management, or use in imaging systems. The board also has four countersunk mounting holes.

LBTEK breadboards feature rounded corners on all edges.

Product Model | Material | Breadboard length | Breadboard width | Center Hole Diameter | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| MBB-4560C | 6061-T6 aluminum alloy | 600 mm | 450 mm | Ø100 mm | $350.26 | today | Add Cart | ||

| MBB-3045C | 6061-T6 Aluminum Alloy | 450 mm | 300 mm | Ø50 mm | $185.65 | today | Add Cart |