Specifications

Assembly

Feedback

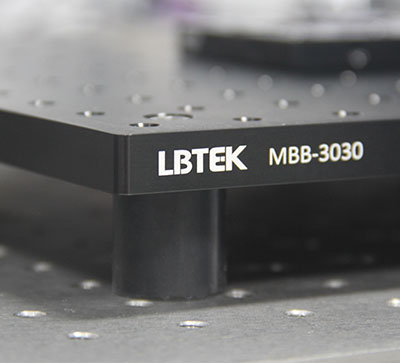

Product Description

- Breadboard Handles

- Vertical Mounting Bracket

- Vibration-Damping Rubber Feet

- Right-Angle Adapter Plate

In addition to providing standard solid aluminum optical breadboards, LBTEK offers a variety of breadboard accessories, including breadboard handles, vertical mounting brackets, right-angle adapter plates, and vibration-damping rubber feet, to facilitate users in more flexibly installing and using breadboards. Besides standard sizes, custom breadboard services with different sizes, shapes, and drilled holes are also available. Please contact LBTEK technical support if needed.

Attributes

Applicable ProductsBreadboard

Breadboard handle materialUADR150 Die-Cast Aluminum Alloy

Vertical fixed mounting bracket material6061-T6 Aluminum Alloy

Vibration isolation rubber base materialRubber/Metal

Breadboard Handle Surface FinishBlack Anodized

Vertical Fixed Mount Surface FinishBlack Anodized

Compatible screw specificationsM6

Breadboard Handles

- Material: 6063-T5 Aluminum Alloy

- Countersunk Mounting Hole: M6

- Load Capacity (Single Handle): 50 Kg

The LBTEK Breadboard Handle MBBH1 is installed on an optical breadboard, featuring an ergonomic arc design for easy transportation of the breadboard. The handle has a hole spacing of 150 mm, with countersunk mounting holes at both ends. It is secured to the LBTEK optical breadboard using two M6 hex socket head cap screws. Each handle can bear a load of 50 kg. Small-sized breadboards only require two handles, while larger breadboards can accommodate multiple handles simultaneously. Note: Before moving the breadboard, please assess the total weight to avoid damage caused by handle bending or breakage.

LBTEK Breadboard Mounting Handle for Easy Transportation and Use

Product Model | Material | Single handle load-bearing capacity | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| MBBH1 | UADR150 Die-Cast Aluminum Alloy | 50 Kg | $16.08 | today | Add Cart |

Vertical Fixed Mounting Base

- Material: 6061-T6 Aluminum Alloy

- Compatible Screw Specification: M6

- For Breadboard 90° Vertical Mounting

- Includes 4 M6 x 30 Hex Socket Head Cap Screws

The LBTEK vertical mount is used to vertically install breadboards onto optical platforms. The right-angled edges feature M6 waist-shaped mounting slots (with lengths of 60 mm and 150 mm respectively), greatly enhancing installation flexibility. LBTEK can provide customization services for other specifications. For special requirements, please contact technical support.

Vertical fixed mounts are commonly used for 90° vertical installation of breadboards.

Product Model | Material | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| VB-450-P2 | 6061-T6 Aluminum Alloy | $256.91 | today | Add Cart | ||

| VB-450 | 6061-T6 Aluminum Alloy | $133.88 | today | Add Cart | ||

| VB-300-P2 | 6061-T6 Aluminum Alloy | $141.07 | today | Add Cart | ||

| VB-300 | 6061-T6 Aluminum Alloy | $74.26 | today | Add Cart |

Vibration Isolation Rubber Bases

- With M6 Threaded Holes, Can be Directly Mounted onto a Breadboard

- Four Pieces Per Pack (Includes 4 M6×10 mm Hex Socket Head Cap Screws)

- Made of Nitrile Rubber, Odor-Free

The LBTEK vibration isolation rubber base is used to support breadboards, providing passive vibration isolation effects. The overall dimensions of the LBTEK rubber base are φ25 mm x 25 mm, with a metal block embedded in the center. The metal block features an M6*6.3 mm threaded hole at its center for connecting to the breadboard.

LBTEK vibration isolation rubber base set of 4, mainly used for breadboard vibration isolation

Product Model | Base Specifications | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| AVF25 | Ø 25 mm*25 mm | $10.98 | today | Add Cart |

Right-Angle Adapter Plates

- M6 Tapped Hole ×12

- M6 Countersunk Slot ×2

The right-angle adapter plate from LBTEK features M6 countersunk waist slots and M6 tapped holes for securing and connecting mechanical components. It is machined from a solid aluminum block, ensuring precision and rigidity. Purchasing the LBTEK RAP-90A right-angle adapter plate comes with 2 complimentary M6 socket head cap screws.

Right-angle adapter plate is designed for vertical mounting of breadboard.

Product Model | Extented length | Overall dimensions | Mounting hole | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| RAP60B | 26 mm | 60 mm×57 mm×26 mm | M2/M3/M4 Tapped Holes, M2.5/M3 Countersunk Holes | $42.62 | today | Add Cart | ||

| RAP60 | 56 mm | 60 mm×57 mm×56 mm | M2/M3/M4 Tappeded Holes, M2.5/M3 Countersunk Holes | $45.37 | today | Add Cart | ||

| RAP-90D | 51 mm | 51 mm×51 mm×19 mm | M6 Countersunk slot ×1, M6 Tapped Hole ×3 | $19.61 | today | Add Cart | ||

| RAP-90C | 51 mm | 51 mm×51 mm×19 mm | M6 Countersunk Slot ×2 | $19.61 | today | Add Cart | ||

| RAP-90B | 76.2 mm | 63.5 mm×73.2 mm×76.2 mm | M6 Slot Hole ×4; M6 Tapped Hole ×8 | $57.00 | today | Add Cart | ||

| RAP-90A | 51 mm | 51 mm×51 mm×38 mm | M6 Tapped Hole ×12; M6 Countersunk Slot ×2 | $20.26 | today | Add Cart |