Specifications

Curve

Assembly

Tutorial

Feedback

Product Description

- Substrate Material: UV Fused Silica

- Mounted in Ø25.4 mm Mount

- Microlens Arrays Available in Round and Square

- Commonly Used in Shack-Hartmann Wavefront Sensors

- Dual-Sided AR Coating

LBTEK microlens arrays consist of microlenses arranged in a two-dimensional grid on a UV-grade fused silica substrate, with both sides coated with an anti-reflection film. LBTEK microlenses are fabricated using photolithography technology, which ensures excellent consistency in the shape and position of each microlens. The microlens array spatially divides the wavefront of a light beam into numerous tiny segments, each of which is focused by the corresponding microlens onto the focal plane. Based on this characteristic, the combination of a microlens array and a CCD array can form a Shack-Hartmann wavefront sensor. LBTEK offers two types of microlens arrays: anti-reflection coated and chromium mask. The unit sizes available are 150 μm and 300 μm. The microlens arrays with a unit size of 150 μm feature circular sublenses, while those with a unit size of 300 μm also feature square sublenses. For other requirements, please contact LBTEK technical support.

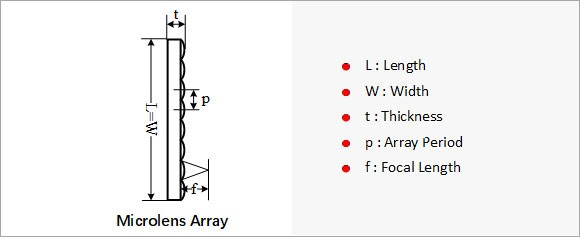

Diagram

Attributes

Optical component materialUV fused silica

Array size10 mm×10 mm

Array thickness1.2 mm

Optical Window Size9 mm×9 mm

Dimensional tolerance+0.0/-0.1 mm

Thickness tolerance±0.05 mm

Mounting base diameter25.4 mm

Mounting base thickness3.5 mm

Microlens array, anti-reflection coating: 400 nm-900 nm

- Substrate Material: UV Fused Silica

- Operating Wavelength Range: 400 nm-900 nm

- Commonly used in Shack-Hartmann wavefront sensors

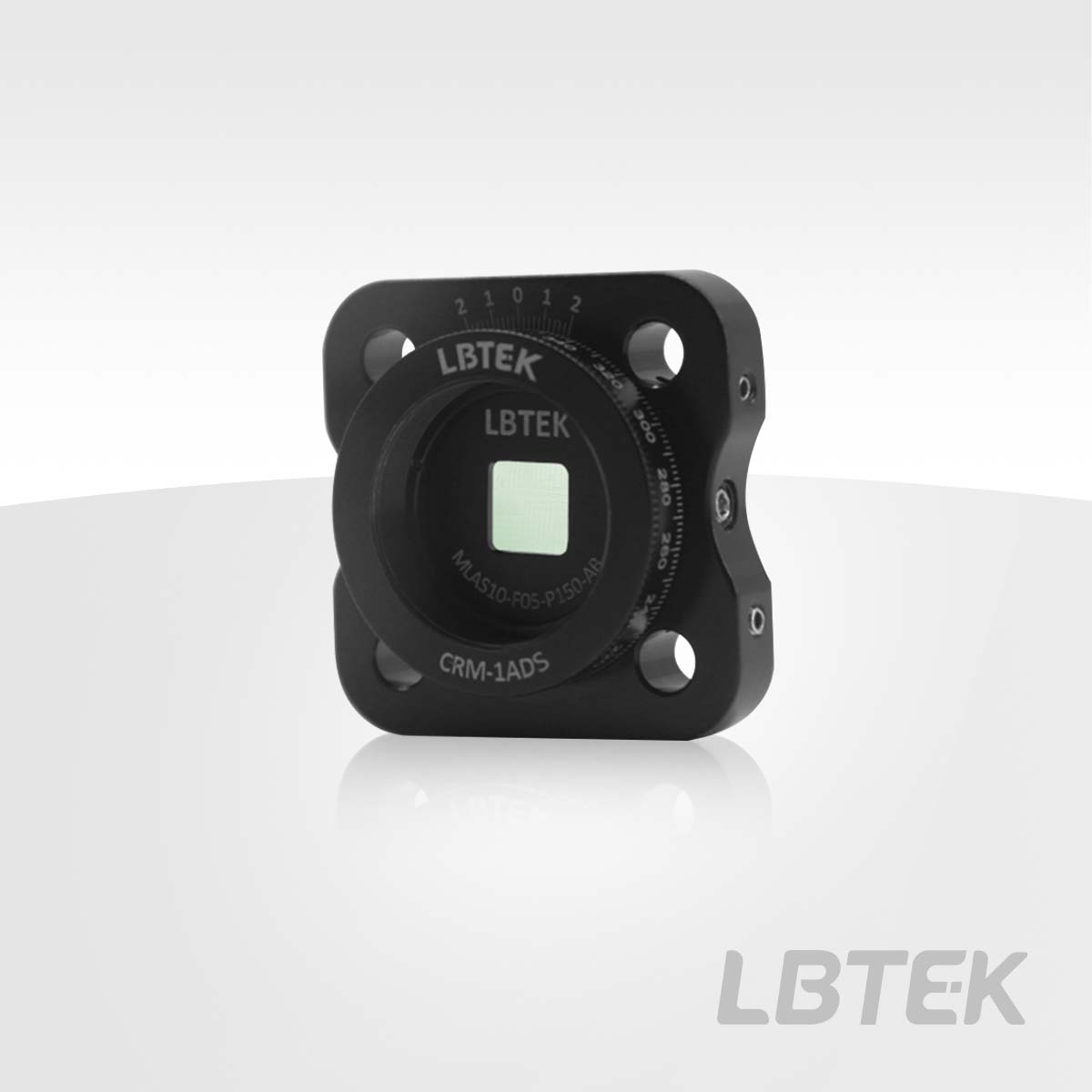

LBTEK microlens arrays are mounted in Ø25.4 mm mounts, which can be installed in all Ø25.4 mm optical component holders. The clear aperture of the mount is 9 mm × 9 mm. LBTEK microlens arrays with 400 nm-900 nm anti-reflection coating are available in two models: MLAS10-F05-P150-AB and MLAS10-F15-P300-AB, with circular and square sublenses respectively.

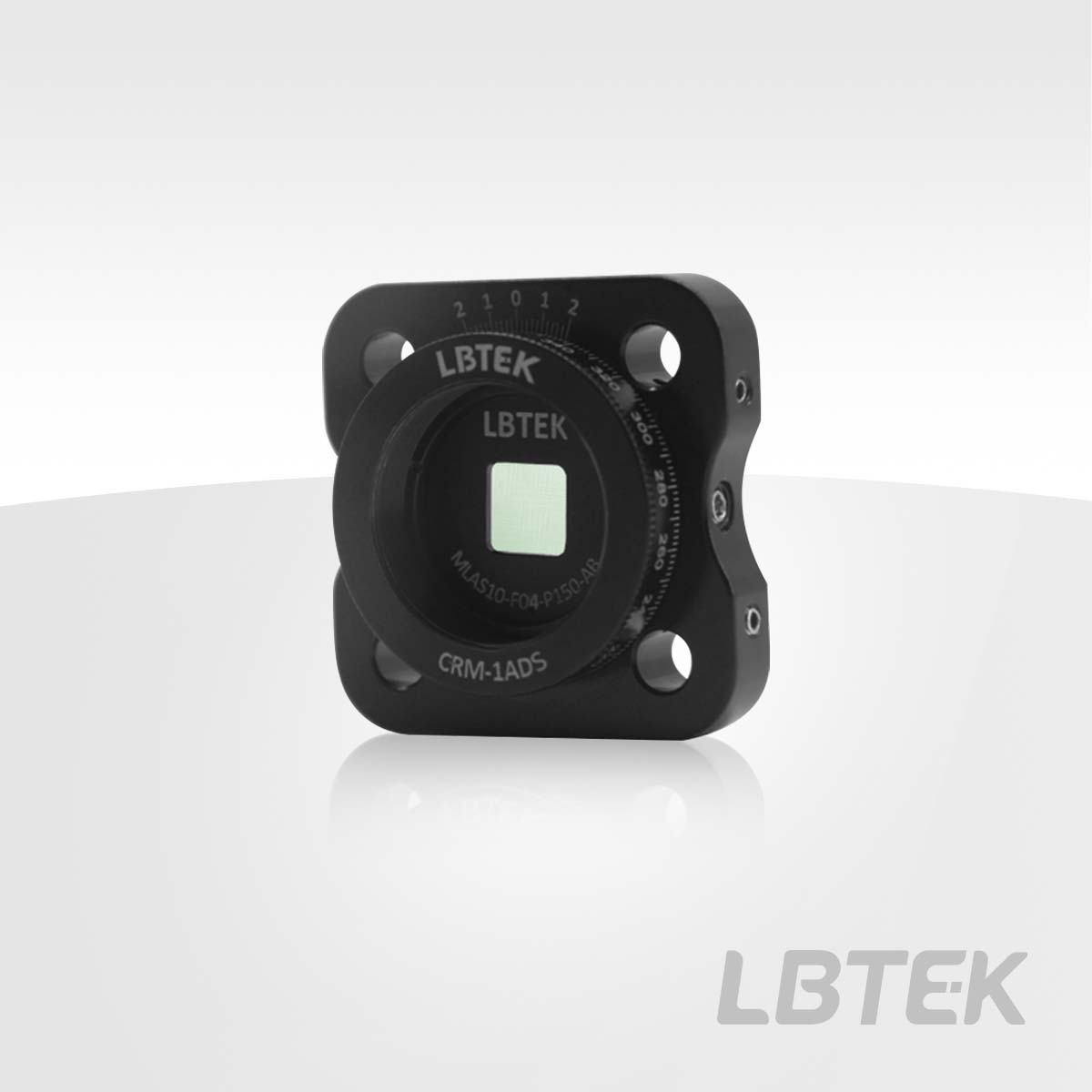

LBTEK microlens array mounted on a 30 mm coaxial system rotary adjustment mount

Product Model | Operating Wavelength | Microlens focal length | Array Period | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| MLAS10-F15-P300-AB | 400 nm-900 nm | 14.6 mm | 300 μm | $473.41 | today | Add Cart | ||

| MLAS10-F05-P150-AB | 400 nm-900 nm | 5.2 mm | 150 μm | $473.41 | today | Add Cart |

Microlens array, chromium mask

- Substrate Material: UV Fused Silica

- Operating Wavelength Range: 300 nm-1100 nm

- Commonly used in Shack-Hartmann wavefront sensors

LBTEK microlens arrays are mounted in Ø25.4 mm mounts, which can be installed in all Ø25.4 mm optical component holders. The clear aperture of the mount is 9 mm × 9 mm. LBTEK microlens arrays with chromium masks are available in one model, MLAS10-F04-P150-AB, with circular sublenses.

LBTEK microlens array mounted on a 30 mm coaxial system rotary adjustment mount

Product Model | Operating Wavelength | Microlens focal length | Array Period | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| MLAS10-F04-P150-AB | 300 nm-1100 nm | 4.1 mm | 150 μm | $473.41 | today | Add Cart |