- Made of heat-treated 316L stainless steel with low thermal expansion coefficient

- Multiple optical component mounting methods

- 440C stainless steel balls and sapphire seats, wear-resistant with low friction coefficient

- For mounting optical components with a diameter of 25.4 mm

- 2 precision adjusters with knurled locknuts

- Adjustable angle ±4°

- Adjustment precision: 0.37°/rev

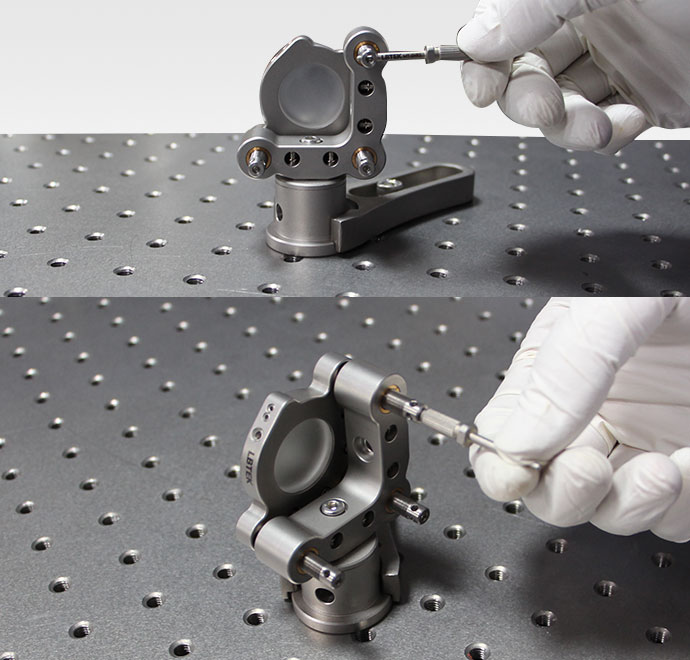

LBTEK 1-inch Clear-Edge Stainless Steel Mirror Mount with openings on the edges, allowing the beam to reflect from one mount to another at a small incident angle θ; rubber-tipped screws secure the optical component, compatible with mounting diameters of 25.4 mm and minimum thickness of 3 mm; M6×0.25 precision adjusters for pitch/yaw adjustment of the optical component with a range of ±4°; additionally, the adjusters feature knurled nuts for locking; the optical mount has M4 countersunk mounting holes on the side, and comes with 2 M4×12 pan head screws and a 2.0 mm hex key included with purchase.

Stainless steel mirror mount can be used with stainless steel posts and non-bridging clamping arms.

Product Model | Optical component mounting method | Adjuster specifications/quantity | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| MT-AM1C2 | Rubber-tipped screw | M6×0.25 Precision Adjuster/2 pcs | $124.20 | today | Add Cart | ||

| MT-AM1C1 | Rubber-tipped screw | M6×0.25 Precision Adjuster/3 pcs | $104.07 | today | Add Cart |

- For optical components with a diameter of 25.4 mm

- 3 precision adjusters, available with or without knobs

- Adjustable angle ±4°

- Adjustment precision: 0.4°/rotation

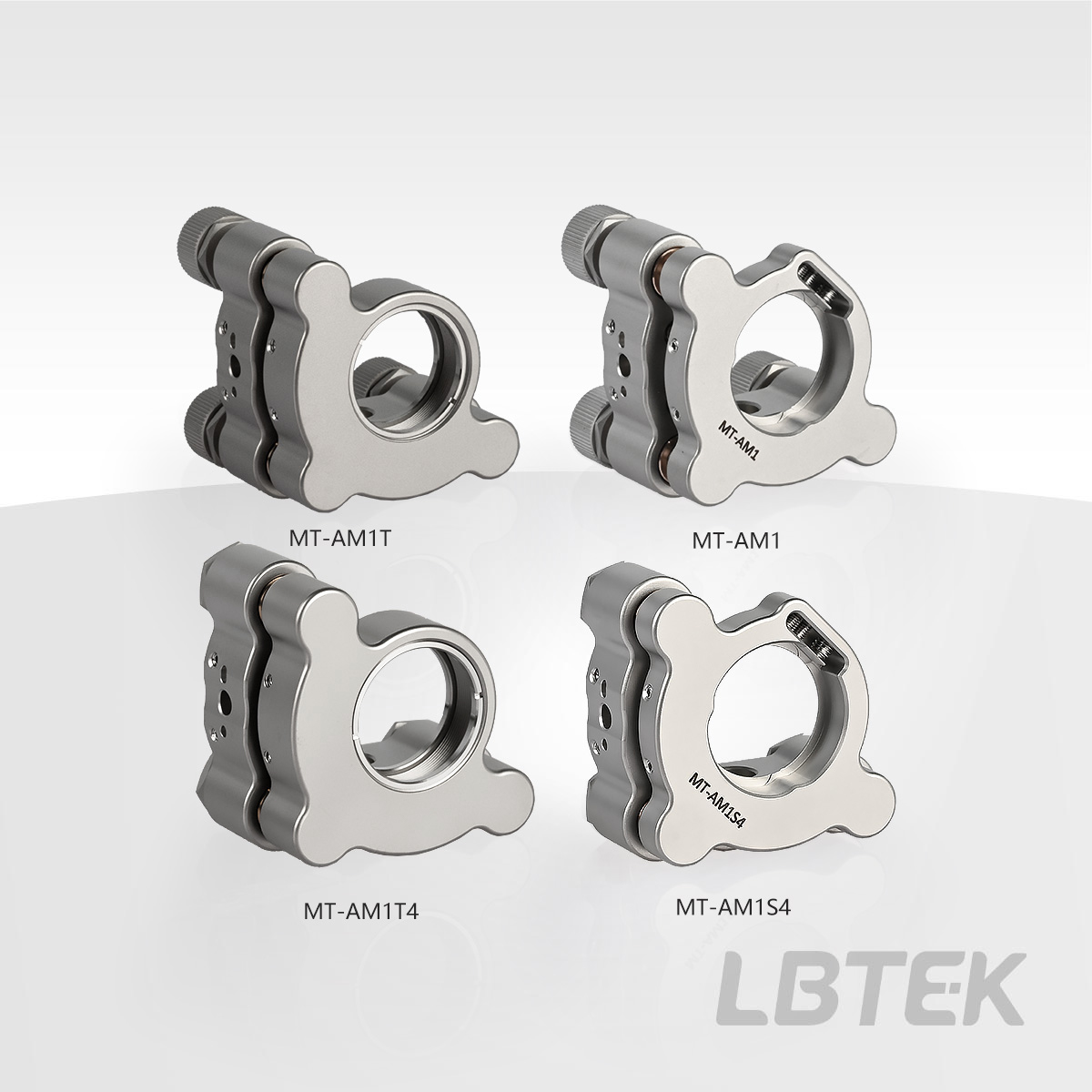

- Two optical component mounting options available

LBTEK 1-inch Stainless Steel Mirror Mount for optical components with a diameter of 25.4 mm. Two low-deformation fixation methods for optical components are available: MT-AM1/MT-AM1S4 uses flexible spring pieces and set screws to secure the optical component, with a minimum thickness of 2 mm for the optical component; three M6×0.25 precision adjusters are used to adjust the pitch/yaw of the optical component, with options for versions with or without knobs. The knob version can be adjusted by hand or with a hex key, while the non-knob version requires a hex key. The optical adjustment mount features M4 countersunk mounting holes on the side. The MT-AM1Tx series employs retaining rings to directly fix the optical component, with two stainless steel retaining rings included with the purchase of the mount. The maximum thickness for optical components fixed with retaining rings is 8 mm. Each purchase includes two M4 thin-head hex screws and a 2.0 mm hex key.

Stainless steel mirror mounts can be used with stainless steel posts and gnon-bridging clamping arms.

Product Model | Optical component mounting method | Adjuster specifications/quantity | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| MT-AM1T4 | Retaining ring | Knobless M6×0.25 Precision Adjuster / 3 pcs | $115.44 | today | Add Cart | ||

| MT-AM1T | Snap ring | Knurled knob M6×0.25 precision adjuster/3 pcs | $120.80 | today | Add Cart | ||

| MT-AM1S4 | Flexible spring piece and set screw | Knobless M6×0.25 Precision Adjuster / 3 pcs | $89.95 | today | Add Cart | ||

| MT-AM1 | Flexible spring piece and set screw | Knurled knob M6×0.25 precision adjuster/3 pcs | $91.65 | 2 weeks | Add Cart |

- For optical components with a diameter of 25.4 mm

- Precision adjuster with side holes, multiple adjustment methods

- Adjustable angle: ±4°

- Adjustment precision: 0.4°/turn

- Locknut available

- Flexible spring piece and set screws securing optical components

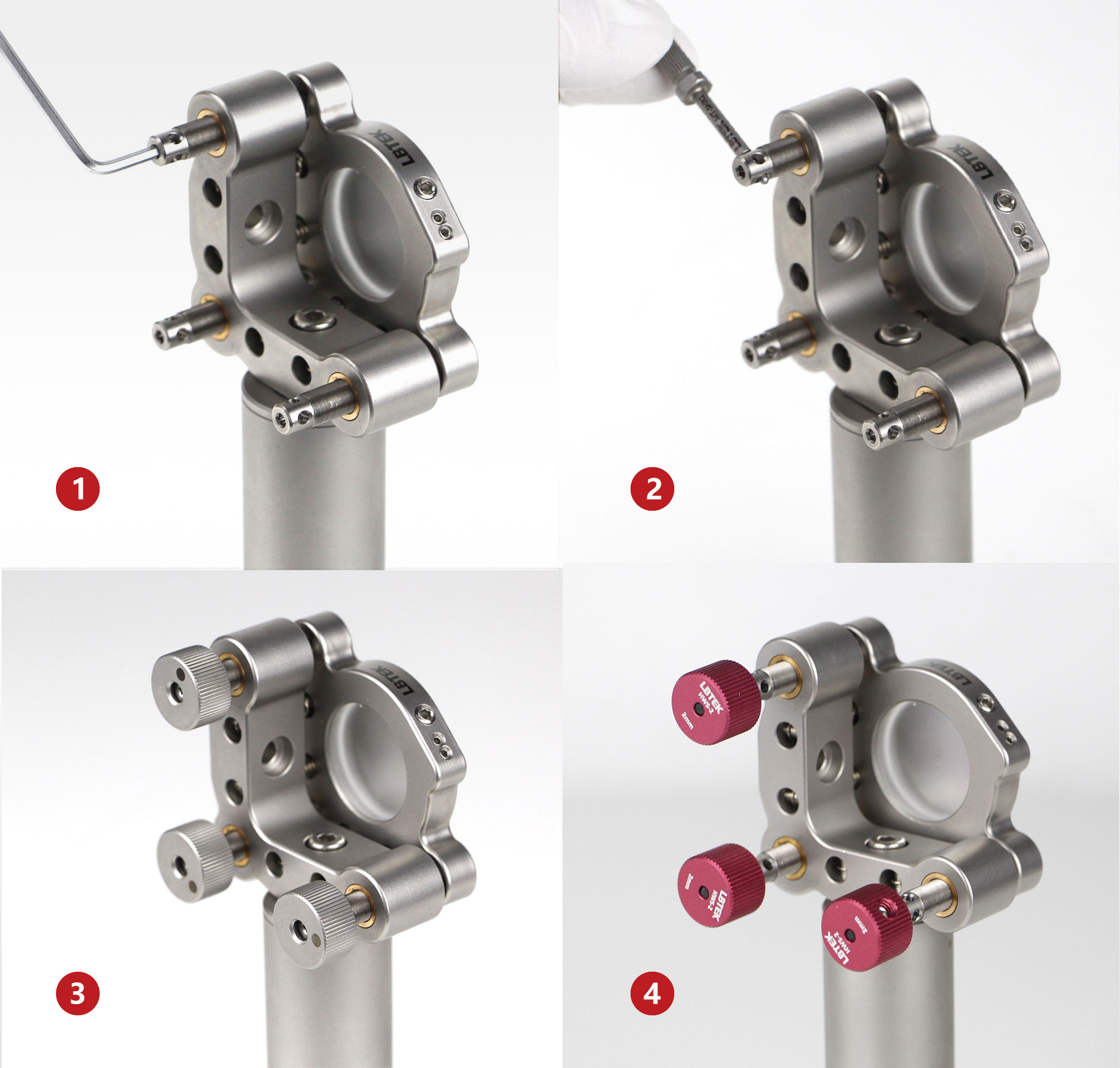

LBTEK 1-inch Stainless Steel Mirror Mounts are for optical components with a diameter of 25.4 mm. The optical components are secured using flexible spring pieces and set screws, with a minimum thickness requirement of 2 mm. The M6×0.25 precision adjuster with side holes is used for adjusting the pitch/yaw of the optical component, offering multiple adjustment methods as shown in the right figure: Figure 1: Direct adjustment using a 2.0 mm hex key at the end of the adjuster; Figure 2: Adjustment using the MT-SHR1 side-hole adjustment key; Figure 3: Installation of the MT-HWS1 removable knob for adjustment; Figure 4: Fine adjustment using the HWS-2 hex knob. Additionally, users can opt to add the MT-LN1 adjuster locknuts to enhance the locking function based on requirements. The optical mount features M4 countersunk mounting holes on the side. The purchase includes two M4 thin-head hex screws and one 2.0 mm hex key. Furthermore, the MT-AM1S6 comes with two locknuts, and the MT-AM1S2 includes three locknuts.

The adjuster with multiple adjustment methods

Product Model | Optical component mounting method | Adjuster specifications/quantity | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| MT-AM1S2 | Flexible spring piece and set screw | M6×0.25 precision adjuster with side holes/3 pcs | $108.78 | today | Add Cart | ||

| MT-AM1S6 | Flexible spring piece and set screw | M6×0.25 precision adjuster with side holes / 2 pcs | $94.53 | today | Add Cart |

- For optical components with a diameter of 25.4 mm

- 2 precision adjusters, available with or without knobs

- Adjustable angle ±4°

- Adjustment precision: 0.4°/rotation

- Two optical component mounting options available

LBTEK 1-inch Stainless Steel Mirror Mount for mounting optical components with a diameter of 25.4 mm. Two low-deformation mounting methods for optical components are available: the MT-AM1Sx series uses the flexible spring pieces and set screws to secure the optical component, with a minimum component thickness of 2 mm; the MT-AM1Tx series employs retaining rings to directly fix the optical component, and two stainless steel retaining rings are included with the purchase. The maximum thickness for ring-fixed optical components is 8 mm. Two M6×0.25 precision adjusters provide the mount with an angular adjustment range of ±4°. Both knob and knobless versions are available—the knob version can be adjusted by hand or with a hex key, while the knobless version requires a hex key. The optical mount features M4 countersunk mounting holes on the side. The purchase includes two M4 thin-head hex screws and one 2.0 mm hex key.

The stainless steel mirror mount can be used with the stainless steel post and the non-bridging clamping arm.

Product Model | Optical component mounting method | Adjuster specifications/quantity | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| MT-AM1T3 | Retaining ring | Knurled Knob M6×0.25 Precision Adjuster/2 pcs | $113.61 | today | Add Cart | ||

| MT-AM1T1 | Retaining ring | Knobless M6×0.25 Precision Adjuster/2 pcs | $111.13 | today | Add Cart | ||

| MT-AM1S3 | Flexible spring piece and set screw | Knurled Knob M6×0.25 Precision Adjuster/2 pcs | $82.89 | today | Add Cart | ||

| MT-AM1S1 | Flexible spring piece and set screw | Knobless M6×0.25 Precision Adjuster/2 pcs | $80.41 | today | Add Cart |

- For optical components with a diameter of 25.4 mm

- 2 precision adjusters with lock rings (knobless)

- Adjustable angle: ±4°

- Adjustment precision: 0.4°/rotation

- Optical component secured by flexible spring piece and set screw

LBTEK 1-inch Stainless Steel Mirror Mount, with 2 lock rings and vertical actuator adjusters, is designed for mounting optical components with a diameter of 25.4 mm, suitable for situations where there is no space behind the mount to use horizontal adjusters. The optical component is secured using flexible spring pieces and set screws. The 2 M6×0.25 precision adjusters with lock rings (knobless) provide an angular adjustment range of ±4° for the mount. The knobless adjusters are adjusted using a hex key. Additionally, the optical adjustment mount features M4 countersunk mounting holes on the side. The purchase includes 2 M4 thin-head hex screws and a 2.0 mm hex key.

Stainless Steel Mirror Mounts can be used with stainless steel posts and non-bridging clamping arm.

Product Model | Optical component mounting method | Adjuster specifications/quantity | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| MT-AM1S5 | Flexible spring piece | Lock ring without knob M6×0.25 precision adjuster/2 pcs | $199.25 | today | Add Cart |

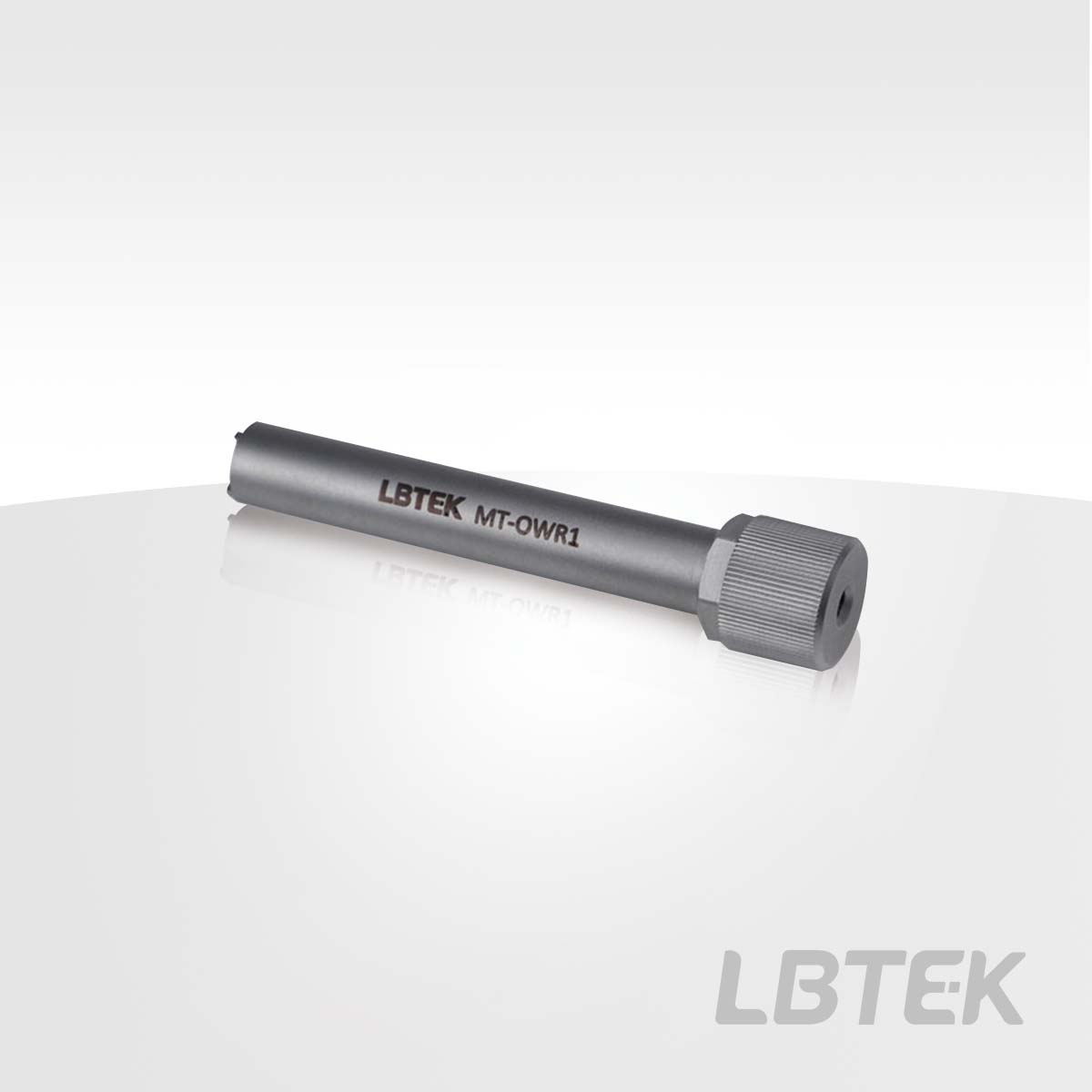

- Combined design of dual wrench heads

- Center-through hole, 2 mm hex keys can pass through the wrench

- Locking ring and thread pair can be adjusted simultaneously

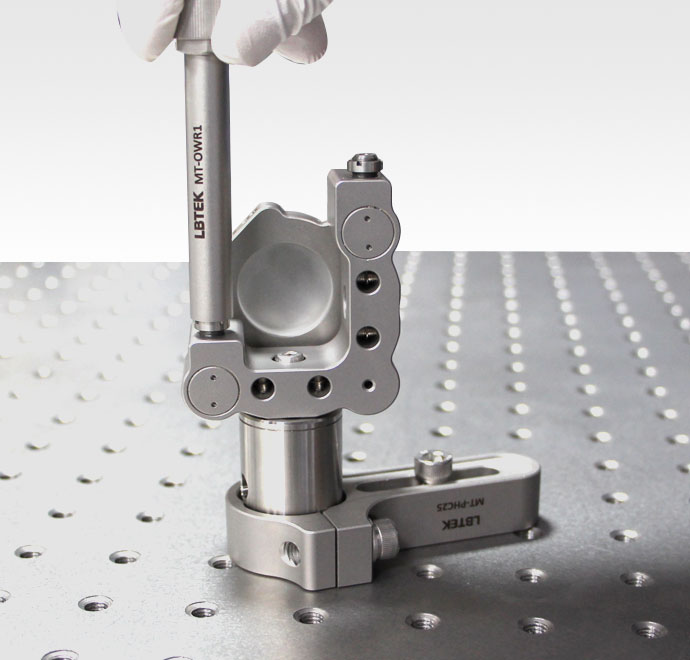

The MT-OWR1 Lock Ring Wrench provided by LBTEK is specifically designed for adjusting the lock rings of MT-AM1S5 stainless steel mirror mounts. It features a dual-wrench-head design, allowing the lock ring adjustment and the threaded pair to be aligned in the same line. The Ø3 mm through-hole at the center of the wrench head enables a 2 mm hex key to pass through the wrench, facilitating simultaneous adjustment of the threaded pair while adjusting the lock ring.

Lock Ring Wrench Adjusting MT-AM1S5 the Lock Ring of the Stainless Steel Mirror Mount

Product Model | Applicable Products | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| MT-OWR1 | MT-AM1S5 | $46.41 | today | Add Cart | ||

| MT-OWR05 | MT-AM05S5 | $41.44 | today | Add Cart |

- Optional hex specifications: 1.3 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm, 5 mm

- Hex socket pin made of S2 alloy steel, replaceable

- Easy adjustment for hex actuator, quick component installation

- Available in kits with multiple size options

LBTEK provides Hex-Key Adjustment Thumb Screws that allow quick adjustment of hex actuators, cap screws, and set screws. Unlike balldriver, they can remain in the hex socket of the screw during adjustment, enhancing convenience. Each size is sold in a set of four thumb screws. Additionally, a kit containing one of each size is also available.

Product Model | Specifications | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| HWS-1.5 | 1.5 mm | $24.19 | today | Add Cart | ||

| HWS-1.3 | 1.3 mm | $24.19 | today | Add Cart | ||

| HWS-KIT | 1.3 mm、1.5 mm、2 mm、2.5 mm、3 mm、5 mm | $40.01 | today | Add Cart | ||

| HWS-5 | 5 mm | $23.66 | today | Add Cart | ||

| HWS-3 | 3 mm | $24.19 | today | Add Cart | ||

| HWS-2.5 | 2.5 mm | $24.19 | today | Add Cart | ||

| HWS-2 | 2 mm | $23.27 | today | Add Cart |

- Ø1.7 mm high-precision tip for adjusting mounts with threaded side holes

- Handle end with a 2.0 mm hex key head

- Made of weakly magnetic stainless steel

The LBTEK Side Hole Adjuster features a high-precision Ø1.7 mm tip for adjusting MT-series mirror mounts with threaded side holes. The handle end is equipped with a 2.0 mm hex head, allowing it to function as a 2.0 mm hex key. The central nut is compatible with a 6.0 mm key, forming an extended leverage arm. With a total length of 36.1 mm, it enables 360° adjustment of threaded side-hole components for optical mounts with diameters of 25.4 mm or larger, without interfering with other threaded components on the back of the mount. The side-hole adjuster is made of weakly magnetic stainless steel, facilitating retrieval with a magnet in confined spaces.

Can be used to adjust MT series mirror mounts with side holes on the screws

Product Model | Applicable Products | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| MT-SHR1 | Threaded pair with side hole | $30.72 | today | Add Cart |

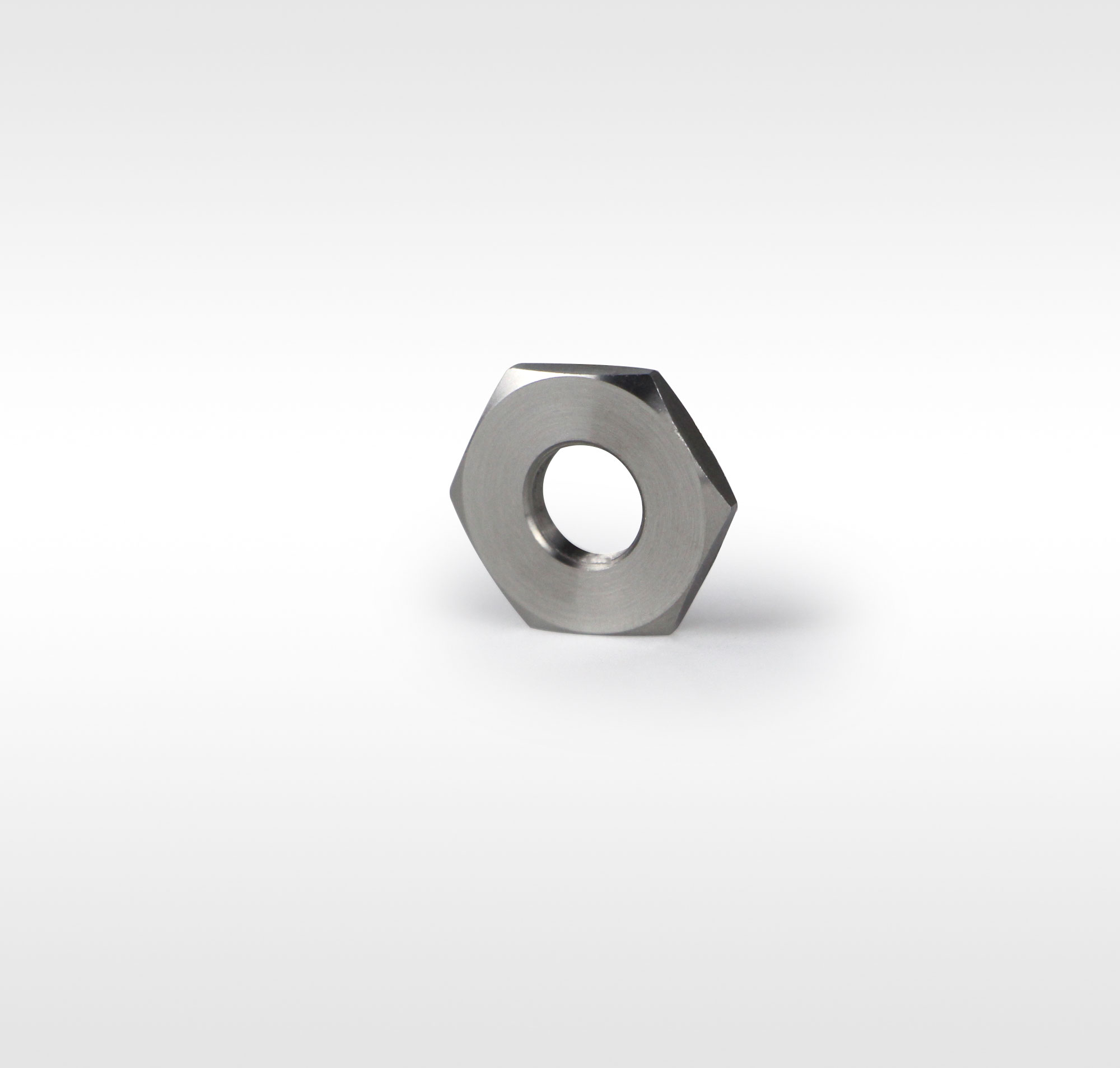

- Locknut ensuring long-term stability of the adjuster

- Thickness 2.0 mm

- Adjustable with 13 mm hex wrench

LBTEK M6×0.25 mm Locknut, suitable for all adjustment mounts with M6×0.25 mm adjusters, providing long-term stability for the mount and resistance to impact and vibration. With flexible usage scenarios, for applications requiring frequent adjuster tuning, simply hand-tighten the locknut (torque approximately 0.03-0.06 N·m). For long-term stability, use the MT-TW13 torque wrench to tighten, achieving a torque of up to 0.23 N·m. Note: To avoid cross-threading the locknut, place it against the adjuster, rotate the locknut until slight resistance is felt, then thread the locknut onto the adjuster.

Locknut is used with M6×0.25 mm adjuster.

Product Model | Compatible Regulator Models | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| MT-LN1 | M6×0.25 mm | $4.31 | today | Add Cart |

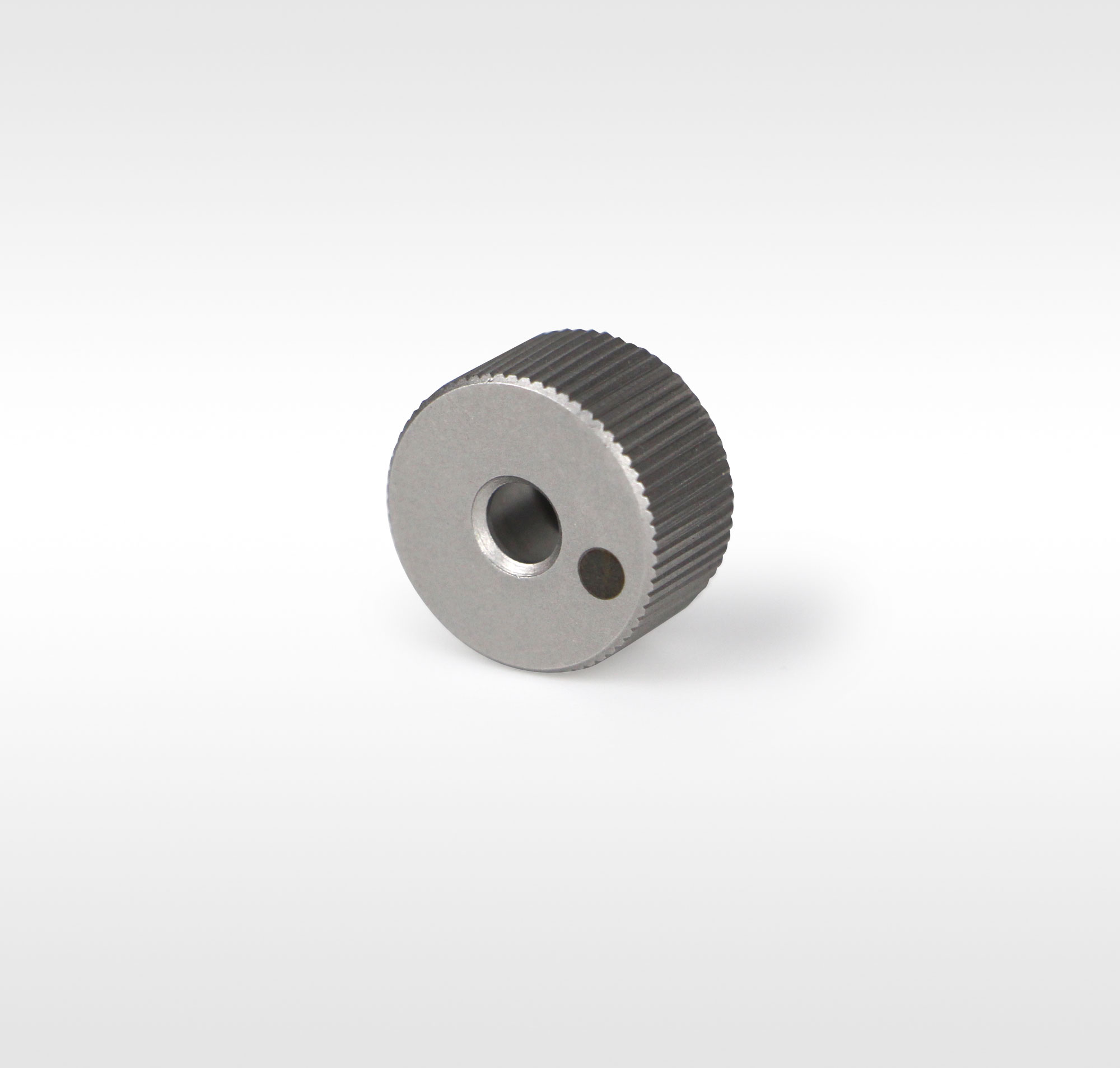

- For M6×0.25 mm adjuster

- Direct screw-in adjuster

- Sold separately

The LBTEK Removable Knobs can be used with MT series M6×0.25 mm adjusters with side holes (such as MT-AM1S2, MT-AM1S6) to enable manual adjustment of the mount by users. When the knob is screwed into the adjuster, the 2 mm hex socket of the adjuster remains accessible. Additionally, the removable knob is compatible with other M6×0.25 mm adjusters. Please note that adding the knob may reduce the adjuster's range of motion, potentially decreasing the mount's adjustable angle. Note: To avoid cross-threading the removable knob, first place it against the adjuster and rotate until slight resistance is felt, then screw the knob into the adjuster.

The removable knob is used with an M6×0.25 mm side-hole adjuster.

Product Model | Compatible Regulator Models | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| MT-HWS1 | M6×0.25 mm | $5.75 | today | Add Cart |