Specifications

Assembly

Software

Feedback

Product Description

- Controller with three-channel, three motor driver chips, capable of connecting three motors simultaneously

- High-resolution microstepping control, suitable for precise positioning

- A user-friendly GUI control software for convenient operation available

- Compact structure, ideal for use in confined spaces

The LBTEK Motorized Filter Mount, driven by a stepper motor, can be used for automated adjustment and control of continuous neutral density filters. The motor features a compact size, suitable for use in confined spaces. The motor exhibits minimal vibration, making it ideal for sensitive experimental environments. The controller is equipped with three motor driver chips, enabling simultaneous connection of three motors to meet diverse control requirements. Users can efficiently conduct experiments using the provided user-friendly GUI control software or use Python-based library functions and sample programs for automated control and customized experiments. With just a few lines of code, the device can be easily integrated into the set systems.

Attributes

MaterialAluminum alloy

Surface treatmentBlack anodized

Motor Type4-wire 2-phase stepper motor

Motorized filter mounts, stepper motor driven

- The motor adopts an all-metal reduction gear design with high output torque

- Stepper control provides precise angle control and repeat positioning

- Unidirectional ultra-high resolution with rotation angle resolution ≤0.02 degrees

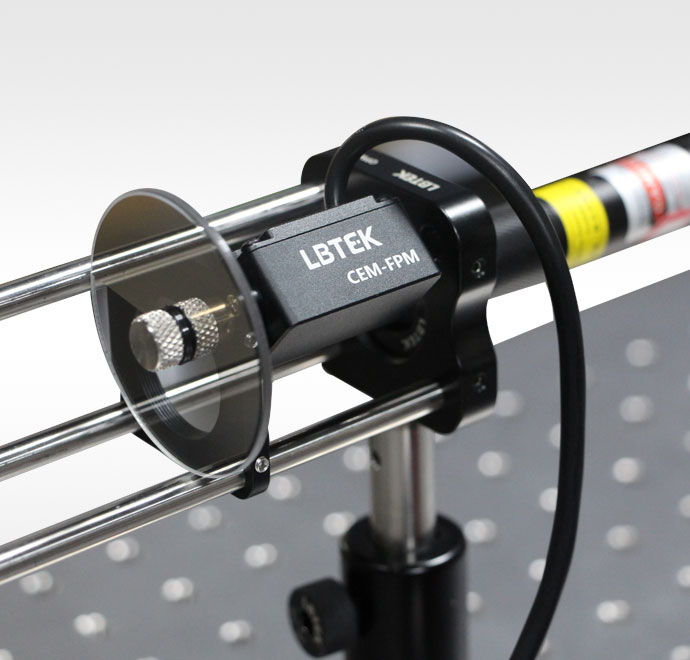

LBTEK Motorized Filter Mount for continuous neutral density filters. The mount utilizes a 10 mm 4-wire 2-phase micro stepper motor with an ultra-compact size, measuring only 18 mm in length and width, making it ideal for use in confined optical paths. Featuring an all-metal reduction gear design, the motor delivers high output torque. Stepper control converts pulse signals into precise angular rotation, ensuring accurate angle control and repeat positioning even in open-loop operation. With high resolution, the unidirectional rotational angular resolution can reach 0.015 degrees.

Compatible with 30 mm coaxial system

Product Model | Applicable Scenarios | Step angle | Unidirectional angular resolution | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| CEM-FPM | 30 mm coaxial system | 1.8° | 0.015° | $351.04 | today | Add Cart | ||

| EM-FPM | Free-space optical path | 1.8° | 0.01° | $302.14 | today | Add Cart |

Stepper motor controller

- Three channels: Provides three motor interfaces for controlling three 4-wire 2-phase stepper motors

- Simple wiring, can directly achieve control and data transmission through USB interface

- Concise yet comprehensive GUI control software

- Python-written source code that supports secondary development

The LBTEK stepper motor controller, when paired with the motorized filter mounts EM-FPM and CEM-FPM, enables automated adjustment and control. The controller features three independent motor driver chips internally and provides three motor interfaces for controlling two 4-wire 2-phase stepper motors. The wiring is simple: one data cable connects to the computer, and one power cable supplies power to the motors. Through a concise yet comprehensive GUI control software, experiments can be conducted efficiently and quickly. Additionally, to facilitate personalized custom experiments, LBTEK provides library functions and sample programs written in Python, allowing easy integration of LBTEK devices into existing systems.

The product includes: 1 power adapter, 1 data transmission cable, and 1 stepper motor controller.

Three-channel controller with three motor interface outputs

Product Model | Number of channels | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| EM-FWC3 | Three-channel | $487.93 | today | Add Cart |