- Linear ball bearing stage, featuring a Gothic arch and four-point contact rolling structure with steel balls with load capacity and high positioning accuracy

- Ball screw drive mechanism with high precision and high transmission efficiency

- Equipped with a stepper motor and end direct-drive structure

- Made of stainless steel, ensuring good strength and rigidity

- Electric stage controller capable of driving the stainless steel electric linear stage

- Table size: 65 mm × 65 mm

- Stroke: 13 mm, 30 mm or 50 mm

- Resolution: 0.5 μm/division or 1 μm/division

- Stainless steel structure with good strength and rigidity

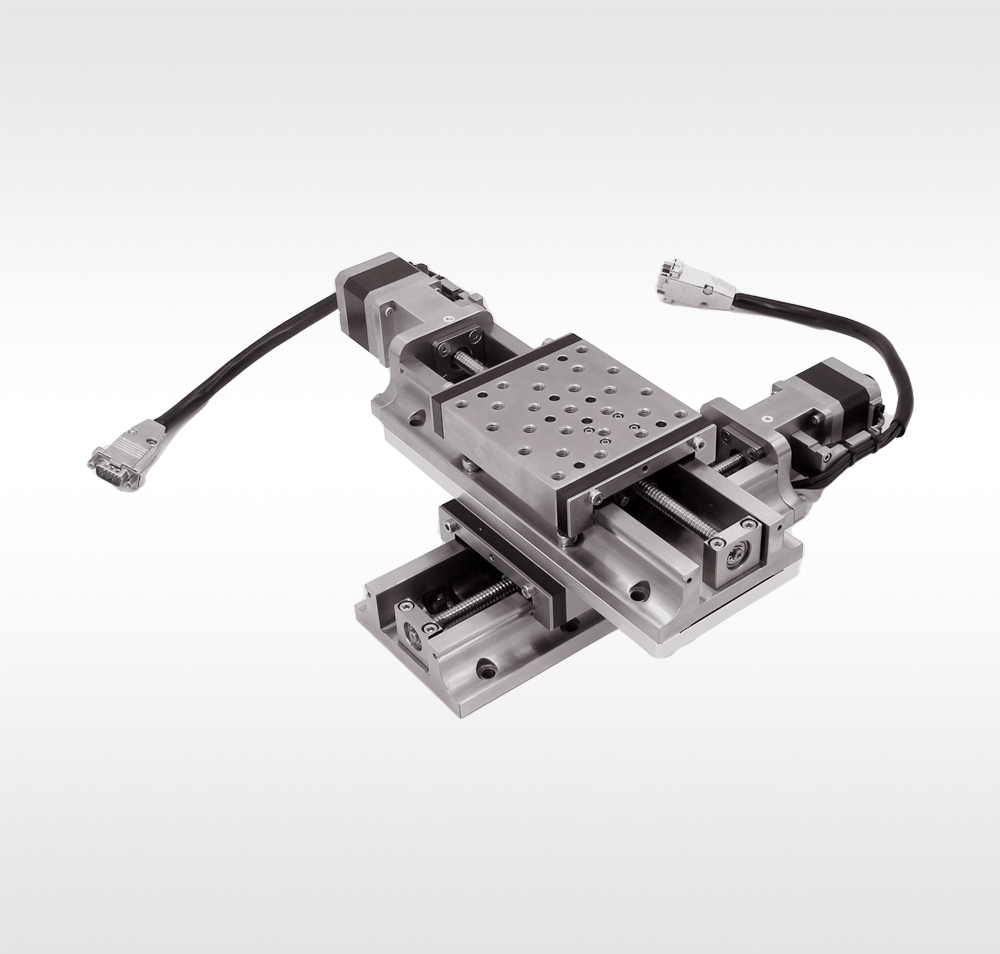

The LBTEK 65 series stainless steel motorized linear stage features a table size of 65 mm × 65 mm, with three linear travel options of 13 mm/30 mm/50 mm. Driven by a stepper motor and ball screw mechanism, the stage achieves precise motion control through linear ball guides. The bottom is equipped with M6 countersunk holes, allowing installation onto optical tables or custom-assembled stage modules using the included M6 low-profile hex socket screws. The table surface has M6 threaded holes spaced 25 mm apart, enabling the assembly of various optical components according to user requirements, and can be used in conjunction with EM-LSS65VA or EM-LSS65VB. The stainless steel motorized linear stage requires an motorized stage controller for operation, with LBTEK offering EM-CV5-x or EM-CS5-x series controllers for user to choose.

Product Model | stroke | Resolution | Motor Type | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| EM-LSS65-50C1 | 50 mm | 0.5 μm/subdivision | Five-phase stepper motor | $1,304.54 | today | Add Cart | ||

| EM-LSS65-13C1 | 13 mm | 0.5 μm/subdivision | Five-phase stepper motor | $811.38 | today | Add Cart | ||

| EM-LSS65-30C1 | 30 mm | 1 μm/division | Five-phase stepper motor | $854.26 | today | Add Cart |

- Table size: 90 mm × 90 mm

- Stroke: 100 mm, 150 mm, 200 mm or 300 mm

- Resolution: 1 μm/division

- Stainless steel structure with good strength and rigidity

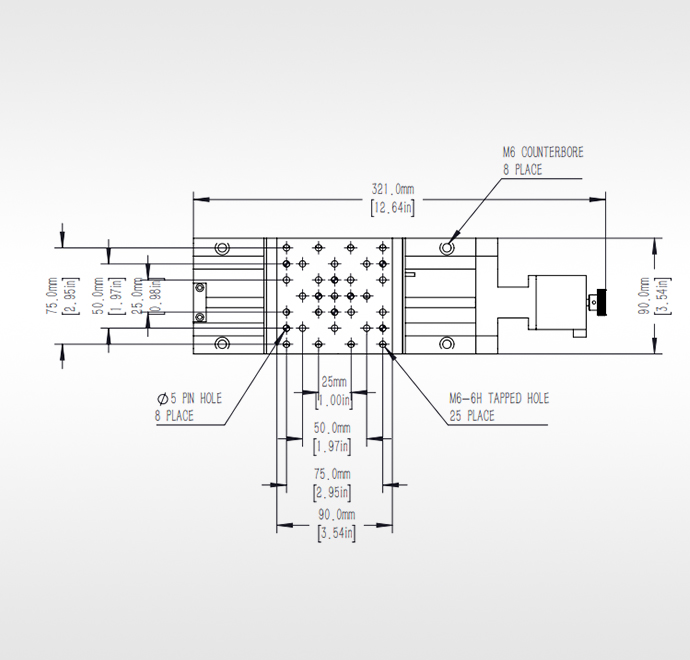

The LBTEK 90 Series stainless steel motorized linear translation stage features a table size of 90 mm × 90 mm, with four linear travel options: 100 mm, 150 mm, 200 mm, and 300 mm. It is driven by a stepper motor and a ball screw mechanism, enabling precise motion control through linear ball bearings. The bottom is equipped with M6 countersunk holes, allowing installation onto optical tables or custom-built translation stage modules using the included M6×20 hex socket head cap screws. The table surface has M6 threaded holes spaced 25 mm apart, facilitating the mounting of various optical components as per user requirements. It can be paired with models such as EM-LSS90VB and EM-LSS90VA. The stainless steel motorized linear translation stage requires an motorized translation stage controller for operation. LBTEK offers the EM-CV5-x or EM-CS5-x series controllers for user to choose.

Product Model | stroke | Resolution | Motor Type | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| EM-LSS90-300C1 | 300 mm | 1 μm/division | Five-phase stepper motor | $2,460.16 | today | Add Cart | ||

| EM-LSS90-200C1 | 200 mm | 1 μm/division | Five-phase stepper motor | $1,785.92 | today | Add Cart | ||

| EM-LSS90-150C1 | 150 mm | 1 μm/division | Five-phase stepper motor | $1,618.58 | today | Add Cart | ||

| EM-LSS90-100C1 | 100 mm | 1 μm/division | Five-phase stepper motor | $1,515.29 | today | Add Cart |

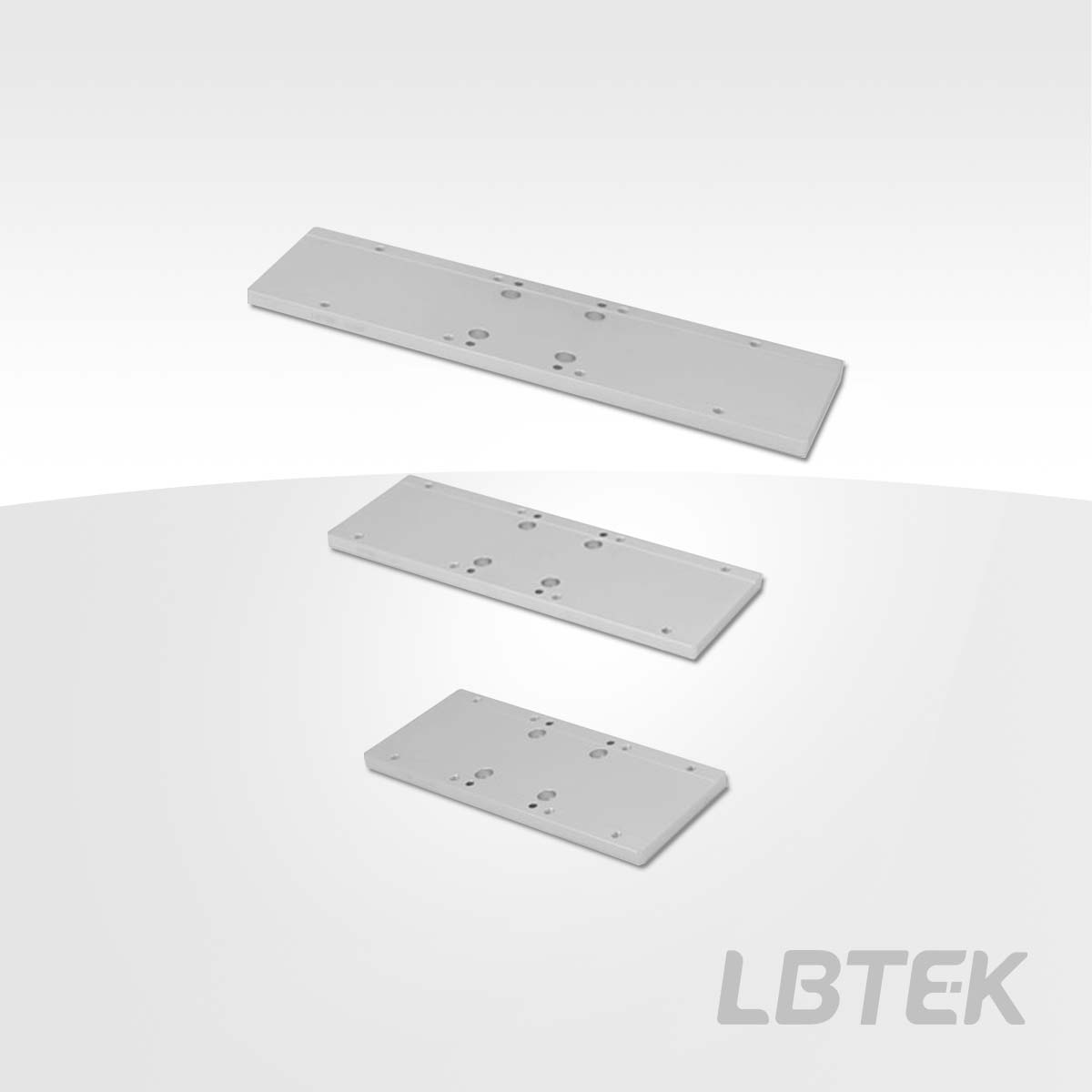

- Main material:Stainless steel or aluminum alloy

- Surface treatment: Passivation or natural anodization

- Mounting hole specifications: M6 tapped hole, M6 countersunk hole

The 65 mm right-angle triaxial adapter plate from LBTEK features four M6 tapped holes and four M6 countersunk mounting holes, compatible with EM-LSS65-50C1, EM-LSS65-30C1, and EM-LSS65-13C1 motorized translation stages. This component enables vertical integration of two translation stages: combining an XY-axis motorized translation stage with a single-axis motorized stage forms an XYZ linear translation stage, while connecting two single-axis motorized translation stages creates an XZ linear translation stage with the right-angle adapter plate.

EM-LSS65VA is typically employed in XYZ-axis translation stage assemblies.

Product Model | Material | Mounting hole center spacing | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| EM-LSS65VB | 6061-T6 Aluminum Alloy | 50 mm | $99.76 | today | Add Cart | ||

| EM-LSS65VA | 303 Stainless Steel | 50 mm | $96.23 | today | Add Cart |

- Able to construct XY-axis translation stage

- Mounting hole specifications: M6 threaded holes, M6 countersunk holes

- Surface treatment: Natural anodized

The 90 mm dual-axis adapter plate provided by LBTEK features 8 M6 threaded holes and 4 M6 countersunk mounting holes, suitable for EM-LSS90-100C1, EM-LSS90-150C1, and EM-LSS90-200C1 motorized translation stages. It is commonly used for vertically crossing and horizontally mounting two translation stages. By using the dual-axis adapter plate, an XY-axis linear translation stage can be constructed. Alternatively, the XY-axis linear translation stage can also be directly assembled from two individual linear translation stages. The dual-axis adapter plate can be selected based on specific requirements.

Product Model | Material | Tabletop size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| EM-LSS90VD | 6061-T6 Aluminum Alloy | 320 mm×90 mm | $71.38 | today | Add Cart | ||

| EM-LSS90VC | 6061-T6 Aluminum Alloy | 270 mm×90 mm | $63.67 | today | Add Cart | ||

| EM-LSS90VB | 6061-T6 Aluminum Alloy | 220 mm×90 mm | $55.17 | today | Add Cart |

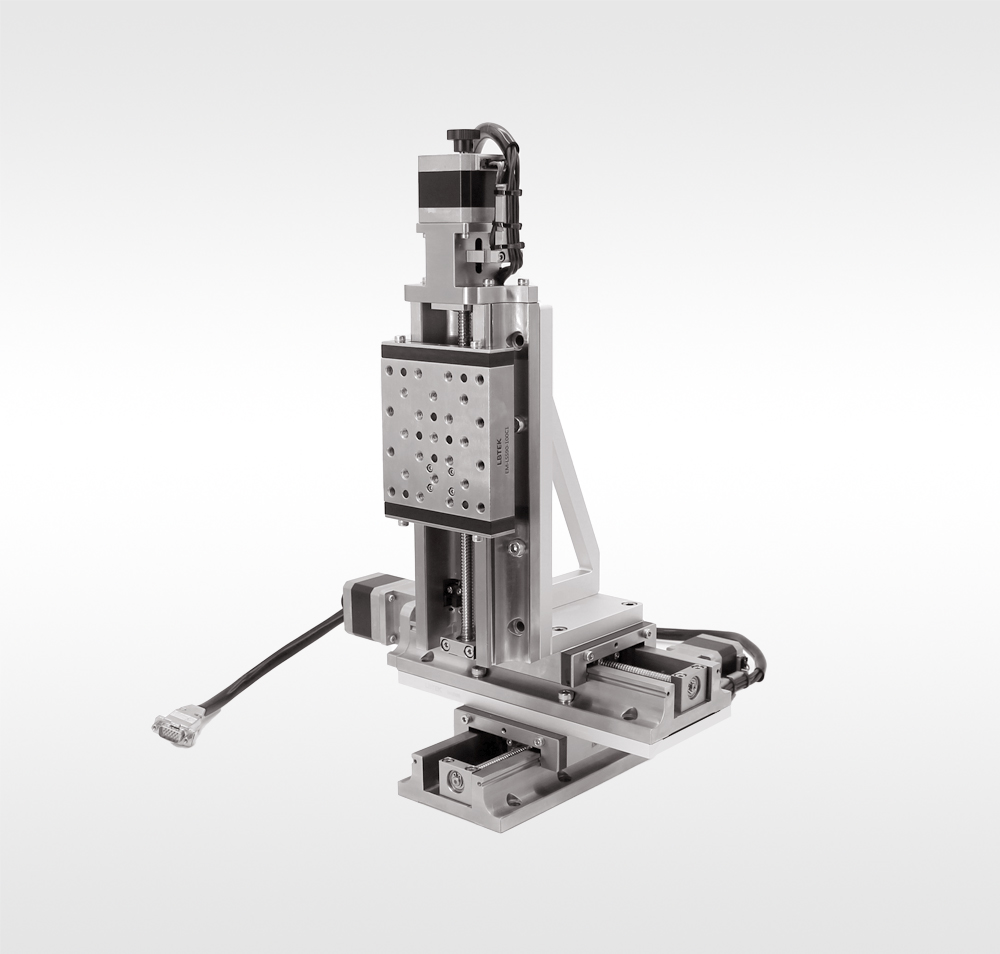

- Able to construct XYZ-axis translation stages

- Mounting hole specifications: M6 threaded holes, M6 countersunk holes

- Surface treatment: Natural anodizing

The 90 mm three-axis adapter plate provided by LBTEK features M6 threaded holes and M6 countersunk mounting holes, suitable for EM-LSS90-100C1, EM-LSS90-150C1, and EM-LSS90-200C1 motorized translation stages. It is commonly used for vertically mounting two translation stages. An XY-axis motorized translation stage and a single-axis motorized translation stage can be combined into an XYZ-axis linear translation stage using a right-angle adapter plate. Similarly, two single-axis motorized translation stages can be assembled into an XZ-axis linear translation stage with a right-angle adapter plate.

Product Model | Material | Tabletop size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| EM-LSS90VF | 6061-T6 Aluminum Alloy | 320 mm×90 mm | $160.29 | today | Add Cart | ||

| EM-LSS90VE | 6061-T6 Aluminum Alloy | 270 mm×90 mm | $142.77 | today | Add Cart | ||

| EM-LSS90VA | 6061-T6 Aluminum Alloy | 220 mm×90 mm | $127.60 | today | Add Cart |