Specifications

Curve

Tutorial

Assembly

Feedback

Product Description

- Optical Material: UVFS

- Available in Versions with and without Through Holes

- Applications: Beam focusing, Collimation, Collection, and Imaging

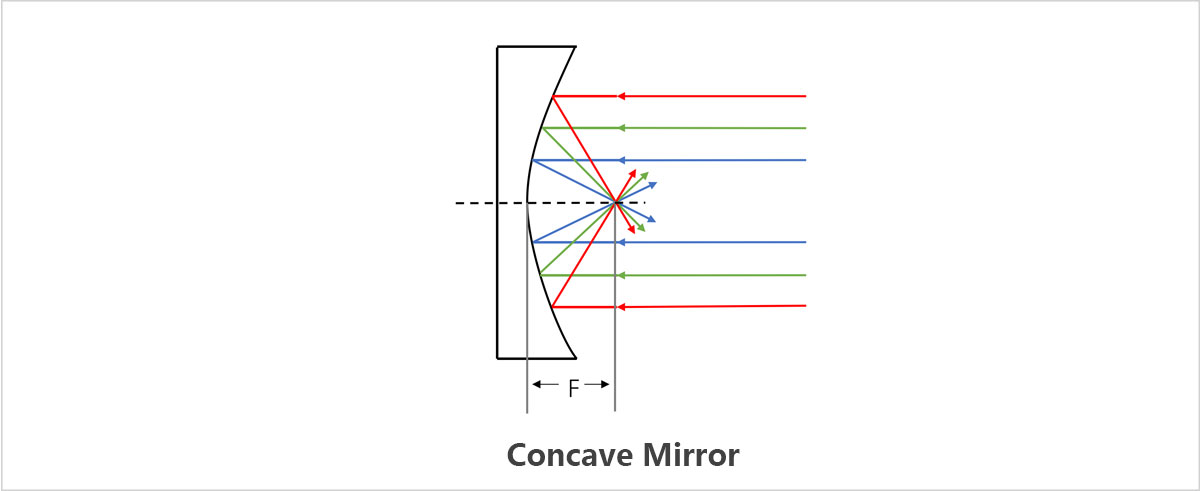

Metal-coated concave mirrors are highly suitable for beam focusing or collimation, beam collection, and other applications with broadband light sources, offering high reflectivity across a wide spectral range. The reflection of light beams on the metal-coated surface does not introduce chromatic aberration. However, metal coatings are prone to oxidation, discoloration, or peeling in high-humidity environments. LBTEK's gold-coated mirrors feature a layer of silicon dioxide protective coating on the surface to isolate the metal coating from direct contact with air, preventing oxidation and maintaining optical performance.

LBTEK offers gold-coated concave mirrors both with and without off-axis holes. All mirrors undergo precision machining and strict quality control to ensure high-quality products for users. For custom metal-coated concave mirrors, please contact LBTEK Technical Support.

Diagram

Attributes

Optical component materialUV fused silica

Clear Aperture>90% CA

Operating Wavelength2.0 μm-20.0 μm

ReflectivityRavg>98%

Surface finish (scratches/pits)40/20

Metal-coated Concave Mirrors with Off-axis Hole

- Substrate Material: UVFS

- Operating Wavelength: 2.0 μm-20.0 μm

- Silicon Dioxide Protective Layer

- Beam Focusing, Collimation, Collection and Imaging

LBTEK offers gold-coated concave mirrors with off-axis holes. Two gold-coated concave mirrors with the same focal length can form a cavity. At least one of the mirrors has a through-hole (central hole or off-axis hole), allowing light to enter and exit through the hole on the concave mirror, undergoing multiple reflections within the cavity before returning to its entry point, which can be used as a Herriot gas absorption cell. LBTEK mirrors with through-holes feature a Ø3.0 mm aperture on the backside with a 60° chamfer. LBTEK gold-coated concave mirrors use UV-grade fused silica as the substrate material, providing higher thermal stability. The surface is coated with a silica protective layer to prevent direct contact between the metal film and air, avoiding oxidation of the metal film that could affect optical performance.

LBTEK mirror mounted in mirror holder AMM-1B

Product Model | Diameter | Focal length | Center Thickness | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| CM10-F100-AU-OH03 | 25.4 mm | -100 mm | 6 mm | $192.19 | today | Add Cart |