Specifications

Feedback

Product Description

- Five types of grit count as one set

- Used for polishing (grinding) fiber optic connectors

- Grit material: Diamond/Silica

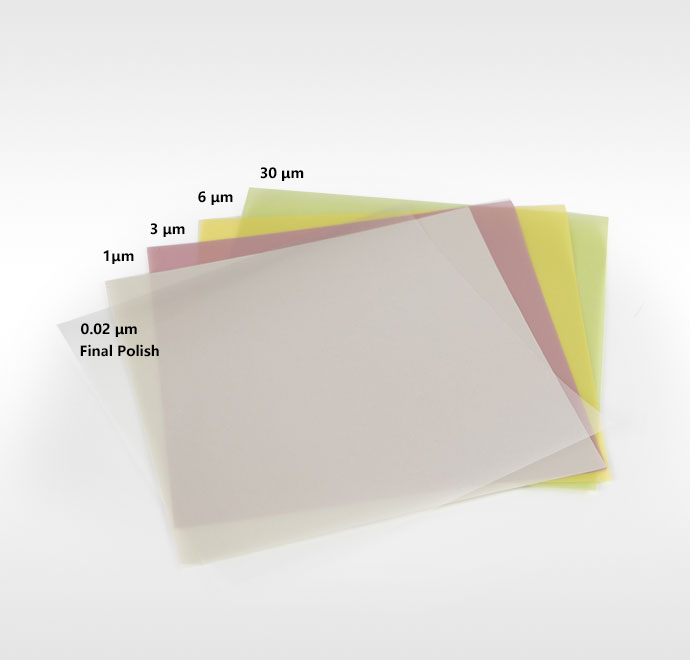

LBTEK Fiber Polishing (Lapping) Film consists of fine abrasive particles bonded to a substrate. By moving the fiber connector across the film, excess material on the ceramic ferrule can be removed to achieve a polished surface. Depending on the grit size, the fiber polishing (lapping) film is available in five grades. For continuous polishing, each stage requires a film with progressively finer grit. Note: The five grades are supplied as a complete set.

Attributes

Material CharacteristicsDiamond / Silica Sand Particles

Size152 mm × 152 mm

Fiber Optic Polishing (Lapping) Films

- Size: 152 mm × 152 mm

- 5 sheets per pack

- Abrasive material: Diamond/Silica

LBTEK Fiber Optic Polishing (Lapping) Films come in 5 types, all with a standard size of 152 mm × 152 mm. For fiber optic polishing, a five-step polishing process is recommended: the first four steps use diamond lapping films with particle sizes of 30 µm, 6 µm, 3 µm, and 1 µm respectively, while the fifth step employs a silica film with a particle size of 0.02 µm. Distilled water should be applied to the film, and an appropriate polishing pad should be selected to perform figure-8 motion polishing. The silica film is manufactured by coating high-precision silica particles, featuring a highly smooth surface with minimal scratches, and it does not contaminate optical fibers during the polishing process.

Fiber Optic Polishing (Lapping) Films

Product Model | Grit Size | Abrasive Material | Size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| GS30D | 30 μm | Diamond | 152 mm×152 mm | $26.93 | today | Add Cart | ||

| GS6D | 6 μm | Diamond | 152 mm×152 mm | $26.93 | today | Add Cart | ||

| GS3D | 3 μm | Diamond | 152 mm×152 mm | $26.93 | today | Add Cart | ||

| GS1D | 1 μm | Diamond | 152 mm×152 mm | $26.93 | today | Add Cart | ||

| GSCF | 0.02 μm | Silicon dioxide | 152 mm×152 mm | $26.93 | today | Add Cart |