- Optical element material: soda-lime glass

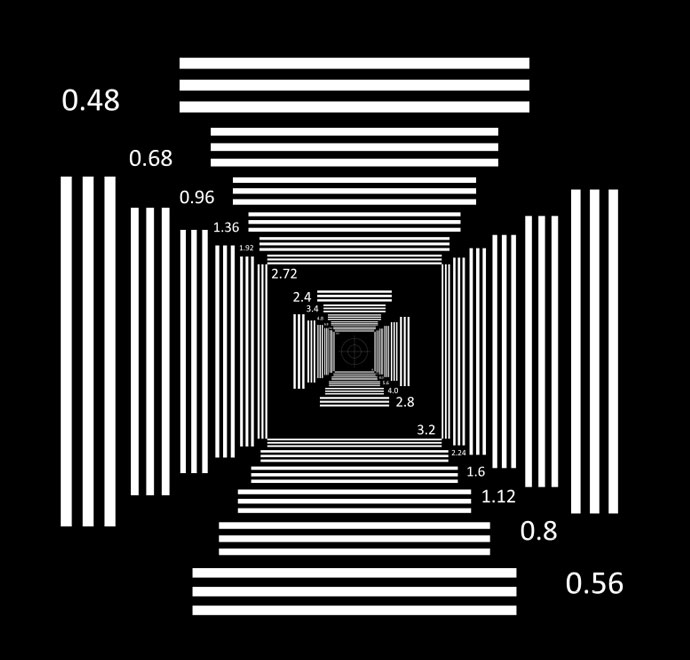

- Resolution: 2.4-80 lp/mm

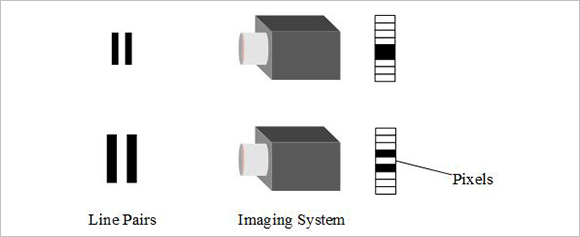

- Commonly used for testing imaging system resolution

- 24 different frequencies

- Optional front or back illumination types

- Crosshairs and concentric circles for alignment available

The LBTEK NBS 1952 test target progresses from the periphery to the center, providing 48 line sets divided into 24 different frequencies. The RTR1BA test target ranges from 2.4 to 80 line pairs per millimeter (one bright line and one dark line), while the RTS3DD test target ranges from 0.48 to 16 line pairs per millimeter (one bright line and one dark line). The NBS 1952 test target features a crosshair at the center measuring 610 µm in both length and width, along with two concentric circles with diameters of 250 µm and 500 µm for alignment purposes. The resolution test target includes both positive (bright field) and negative (dark field) resolution test targets. The positive resolution test target is made by depositing chromium on a soda-lime glass substrate, allowing light to pass through the non-patterned areas. The negative resolution test target, on the other hand, is created by depositing chromium on the substrate, enabling light transmission through the patterned areas.

Product Model | Size | Resolution | Coating | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| RTR1DC-P | Ø25.4 mm | 2.4-80 lp/mm | Chrome (test pattern coating) | $100.80 | today | Add Cart | ||

| RTR1DC-N | Ø25.4 mm | 2.4-80 lp/mm | Chrome (test pattern transparent, other areas coated) | $96.88 | today | Add Cart | ||

| RTS3DD-N | 76.2×76.2 mm | 0.48-16 lp/mm | Chrome (test pattern transparent, other areas coated) | $149.70 | today | Add Cart | ||

| RTS3DD-P | 76.2×76.2 mm | 0.48-16 lp/mm | Chrome (test pattern coating) | $155.58 | today | Add Cart |