- Bi-Telecentric design, ultra-high telecentricity, measurement accuracy improved

- Optional adjustable aperture available, balanced depth of field and resolution

- Compatible with industrial cameras featuring 1.1'' CMOS sensors

- C-Mount optical interface

- Greater depth of field, minimal distortion

- No additional distortion correction required

- Maximum compatible sensor size: 1.1" (14.2 mm × 10.4 mm)

The bi-telecentric lens provided by LBTEK has high telecentricity, high resolution, large depth of field, low distortion, large field of view and unique parallel light design. When used, there is no need to correct additional distortion. The C-Mount interface can be directly connected to industrial cameras without adapter components. The maximum recommended sensor size is 1.1" (14.2 mm×10.4 mm).

A bi-telecentric lens directly connected to industrial cameras

Product Model | Magnification | Aperture | Maximum applicable sensor size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| LB-PTL23819-C | 0.102X | F6.5 | 1.1" | $4,904.10 | 3 weeks | Add Cart | ||

| LB-PTL18219-C | 0.102X | F6.5 | 1.1" | $4,063.44 | 3 weeks | Add Cart | ||

| LB-PTL15219-C | 0.122X | F6.5 | 1.1" | $3,082.88 | 3 weeks | Add Cart | ||

| LB-PTL13719-C | 0.135X | F6.5 | 1.1" | $2,410.87 | 3 weeks | Add Cart | ||

| LB-PTL11019-C | 0.168X | F6.5 | 1.1" | $1,626.42 | 3 weeks | Add Cart | ||

| LB-PTL09219-C | 0.202X | F6.5 | 1.1" | $1,374.09 | 3 weeks | Add Cart | ||

| LB-PTL08019-C | 0.231X | F6.5 | 1.1" | $1,064.89 | today | Add Cart | ||

| LB-PTL06519-C | 0.284X | F6.5 | 1.1" | $947.74 | 3 weeks | Add Cart | ||

| LB-PTL05519-C-VI | 0.336X | F6.5-F35.8 | 1.1" | $882.76 | 3 weeks | Add Cart | ||

| LB-PTL04519-C-VI | 0.411X | F6.5-F35.8 | 1.1" | $721.56 | 3 weeks | Add Cart | ||

| LB-PTL03719-C-VI | 0.504X | F6.5-F35.8 | 1.1" | $655.80 | today | Add Cart |

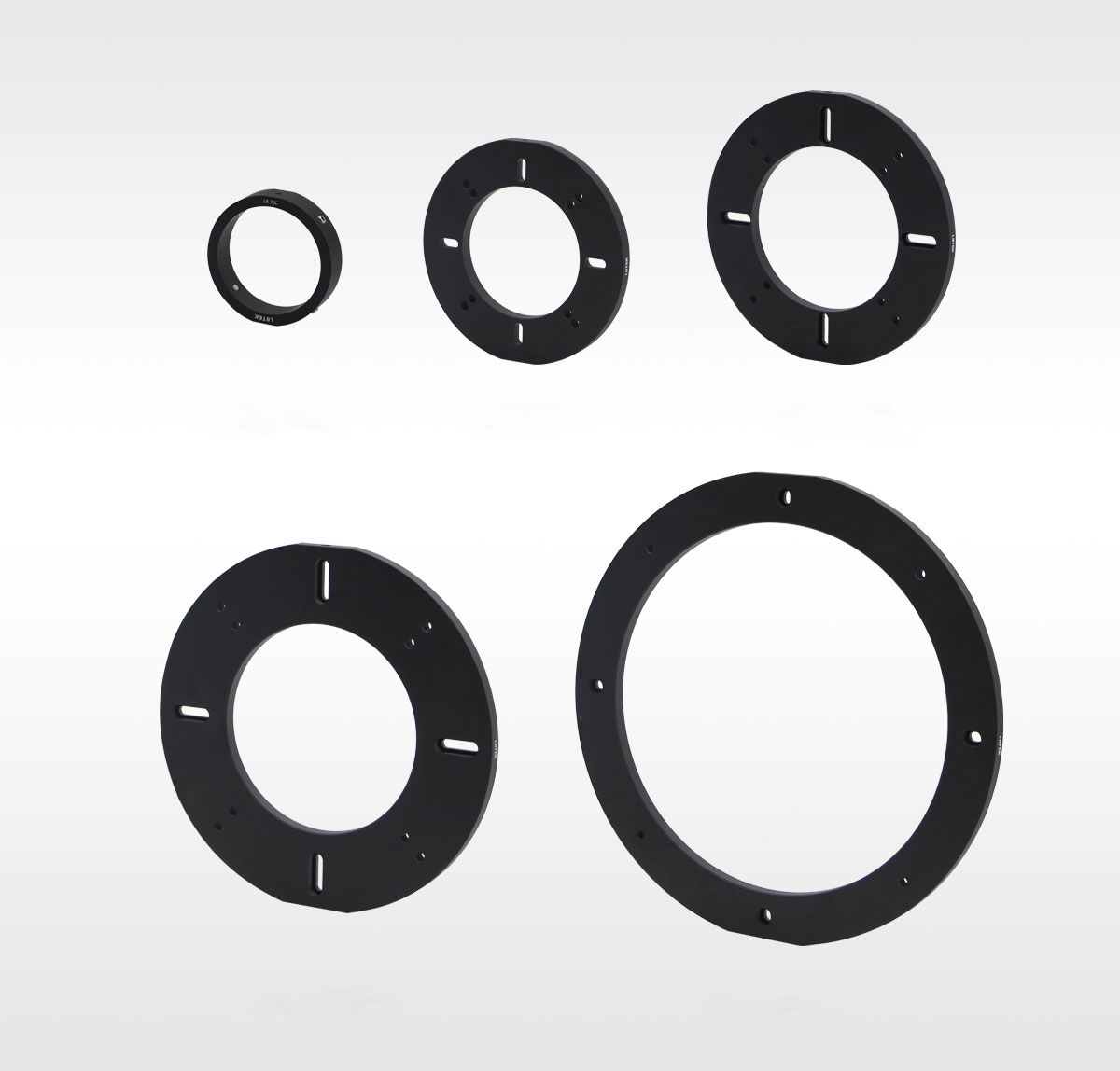

- Bi-Telecentric Lenses Clamps

- Flangeless bi-telecentric lenses are clamped by rubber head screws

- Bi-telecentric lenses with flange are matched with the corresponding flange clamps

The bi-telecentric lens clamps provided by LBTEK are used to clamp bi-telecentric lenses. The clamps are divided into two categories, one is a bi-telecentric lens clamp with a flange, and the other is a bi-telecentric lens clamp with a rubber head screw. The clamp with a flange matches the lens of the corresponding flange size, while the holder with a rubber head screw is used to clamp a cylinder with a diameter of 70 mm. Each holder has one M4 and one M6 threaded mounting hole.

A bi-telecentric lens clamp clamping a bi-telecentric lens

Product Model | Lens mounting method | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| LB-220F | Flange | $67.72 | today | Add Cart | ||

| LB-128F | Flange | $63.67 | today | Add Cart | ||

| LB-109F | Flange | $55.43 | today | Add Cart | ||

| LB-82F | Flange | $44.45 | today | Add Cart | ||

| LB-70C | Rubber Head Screw | $27.19 | today | Add Cart |