Specifications

Tutorial

Assembly

Feedback

Product Description

- Regulate Polarization States between Linear Polarization, Circular Polarization, and Elliptical Polarizationrization

- Provide Pre-assembled Fiber Polarization Controllers

- Three-loop Structure or Compression Structure

LBTEK’s fiber polarization controllers generate stress-induced birefringence by either winding the fiber around a circular disc or by extruding the fiber, thereby creating independent waveplates that alter the polarization state of light propagating through single-mode fibers. The three-loop polarization controller’s three loops respectively function as λ/4, λ/2, and λ/4 waveplates. The extrusion-type polarization controller acts as a rotatable variable waveplate. Both types can convert any input polarization state into the desired output polarization state. Furthermore, the all-fiber structural design significantly reduces the device’s insertion loss and back reflection, enabling it to replace traditional polarization controllers composed of discrete waveplates. LBTEK offers two models: pre-assembled fiber versions and empty devices. These polarization controllers are primarily used with fibers featuring a Ø900 µm protective jacket or Ø250 µm bare fibers.

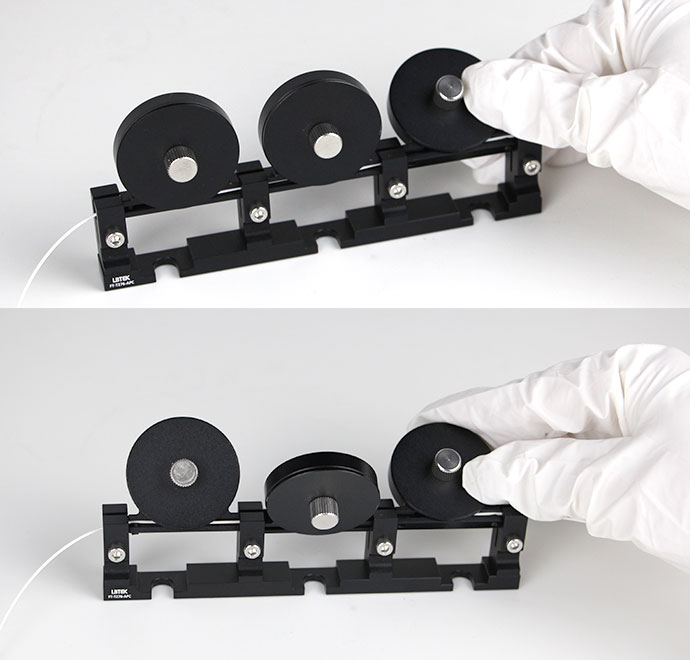

Tri-Loop Polarization Controller

- Three-Rring Type

- Provides Various Ring Diameter Specifications

- Offers Empty Polarization Controllers and Pre-Installed Fiber Optic Controllers

LBTEK's mechanical three-loop polarization control is based on the principle of birefringence induced in optical fibers under external force. The three loops function equivalently as λ/4, λ/2, and λ/4 waveplates respectively. By adjusting the rotation angles of these three loops in coordination, the polarization state of incident light can be transformed into any desired polarization state.

The retardation effect caused by birefringence is primarily determined by the fiber cladding radius, fiber loop radius, and the wavelength of the input light. The number of fiber loops required for different wavelengths can be calculated using the formula provided in the technical specifications.

LBTEK offers two options for polarization controllers: empty polarization controllers and pre-installed fiber polarization controllers. The polarization controllers are mainly designed for use with fibers protected by Ø900 µm sleeves.

Tri-ring fiber optic polarization controller alters the polarization state of light

Product Model | Ring diameter | Fiber Type | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| FT-T56-PC | 56 mm | SMF-28e+ | $173.62 | 3 weeks | |||

| FT-T56-APC | 56 mm | SMF-28e | $187.22 | today | |||

| FT-T29-APC | 29 mm | SMF-28e | $173.1 | 4 weeks | |||

| FT-T56-N | 56 mm | No fiber | $144.99 | today | |||

| FT-T29-N | 29 mm | No fiber | $130.35 | today | |||

| FT-T15-N | 15 mm | No fiber | $125.77 | today |

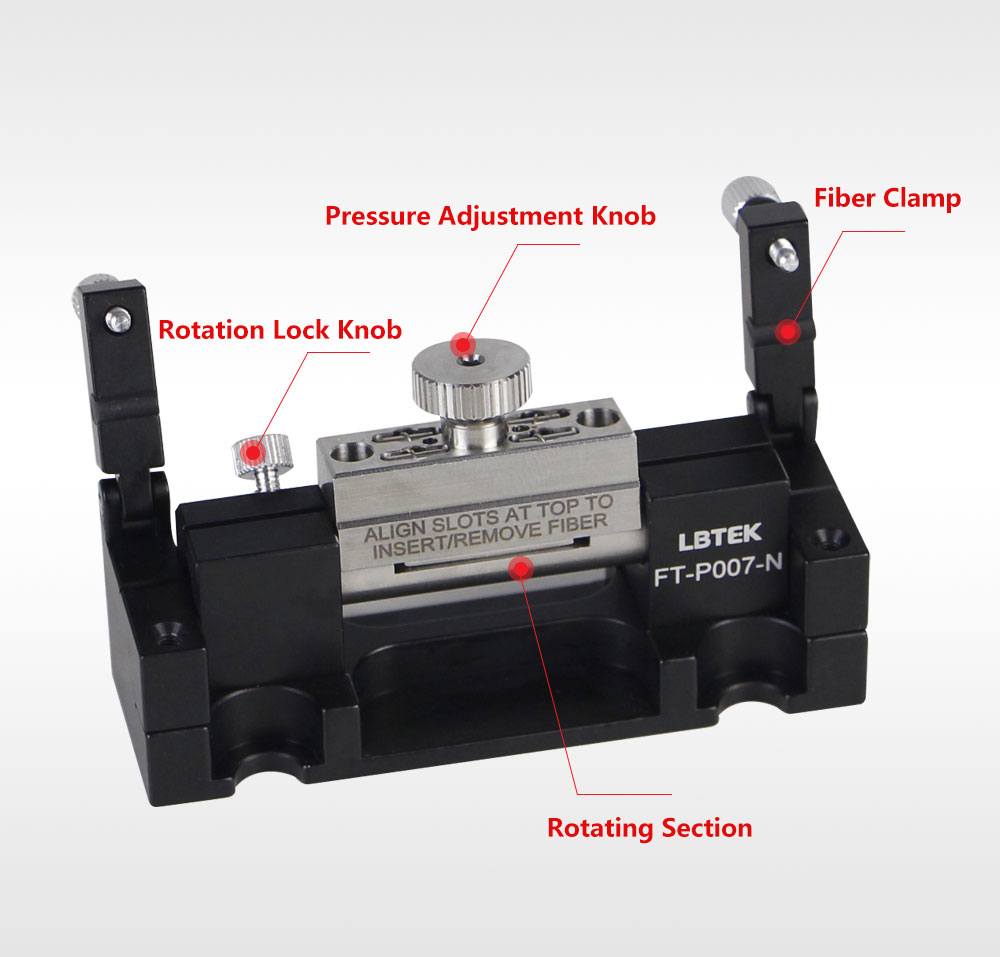

Squeeze-Type Polarization Controller

- Polarization Effect Achieved by Fiber Squeezing

- Compact Design

- Applicable to Fibers with Ø900 µm Tight-Buffered Jacket or Ø250 µm Bare Fibers

LBTEK offers two types of squeeze-type polarization controllers, primarily designed for fibers with Ø900 µm protective sleeves or Ø250 µm bare fibers. Each polarization controller consists of a rotatable fiber squeezer and two fiber clamping blocks. The polarization controller generates stress-induced birefringence within the fiber through mechanical squeezing, effectively functioning as a rotatable variable waveplate. The equivalent waveplate's polarization angle and retardation can be adjusted according to user requirements, enabling the conversion of any input polarization state into the desired output polarization state.

The squeeze-type polarization controller reduces inherent loss and back-reflection loss, serving as an alternative to traditional free-space polarization controllers composed of two quarter-wave plates and one half-wave plate. Among them, the FT-P007-N and FT-P008-N models feature knob screws for fiber locking, offering more convenient operation compared to the FT-P000-N model with cross screws for fiber locking.

Extrusion-type fiber optic polarization controller

Product Model | Control Type | Applicable fiber type | Fiber Mounting Method | weight | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| FT-P008-N | Rotational extrusion type | Ø250 µm bare fiber | Knob flip-cover type | 0.092 kg | $287.11 | today | |||

| FT-P000-N | Rotational extrusion type | Ø900 µm compact buffer jacket fiber | Cross-screw flat plate type | 0.06 kg | $268.15 | today | |||

| FT-P007-N | Rotational extrusion type | Ø900 µm compact buffer layer fiber | Knob flip-cover type | 0.096 kg | $287.11 | today |