Specifications

Curve

Tutorial

Assembly

Feedback

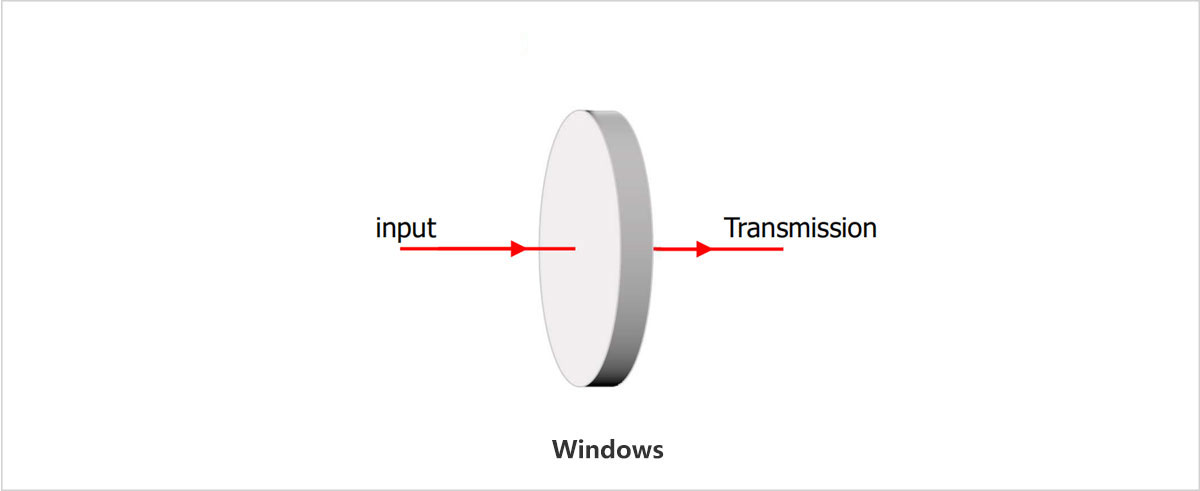

Product Description

- Optical Material: Sapphire

- Working Wavelength: 200 nm -4.5 μm

LBTEK offers sapphire precision windows, which are uncoated and can be applied in the wavelength range of 200 nm to 4.5 μm. Sapphire has extremely high surface hardness and can only be scratched by a few substances. Additionally, sapphire exhibits excellent chemical stability, remaining insoluble in water, common acids, and alkalis even at temperatures up to 1000°C. The transmittance range of sapphire windows covers from the ultraviolet to the mid-infrared spectrum, with high transmittance across the entire wavelength range. For details, see the transmittance curve.

Diagram

Attributes

Optical component materialSapphire

Operating Wavelength200 nm -4.5 μm

Surface finish (scratches/pits)60/40

Surface Flatness (@633 nm)λ

Surface Parallelism≤10 arcsec

Clear Aperture90% CA

Sapphire Windows, Uncoated, 200 nm-4.5 μm

- Working Wavelength: 200 nm -4.5 μm

The transmittance range of sapphire windows covers from the ultraviolet to the mid-infrared band, with high transmittance throughout the entire wavelength range. For details, please refer to the curve below. Our sapphire windows are z-axis cut, effectively eliminating the birefringence effect of transmitted light. All LBTEK circular lenses can be installed in LBTEK standard lens sleeves, fixed lens mounts, and various coaxial mounting plates. Customers can choose the optimal installation method for different application scenarios.

LBTEK Installed Parts

Product Model | Optical component material | Diameter | Clear Aperture | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| OW82 | Sapphire | 25.4 mm | 90% CA | $78.58 | today | Add Cart | ||

| OW81 | Sapphire | 12.7 mm | 90% CA | $42.10 | today | Add Cart |