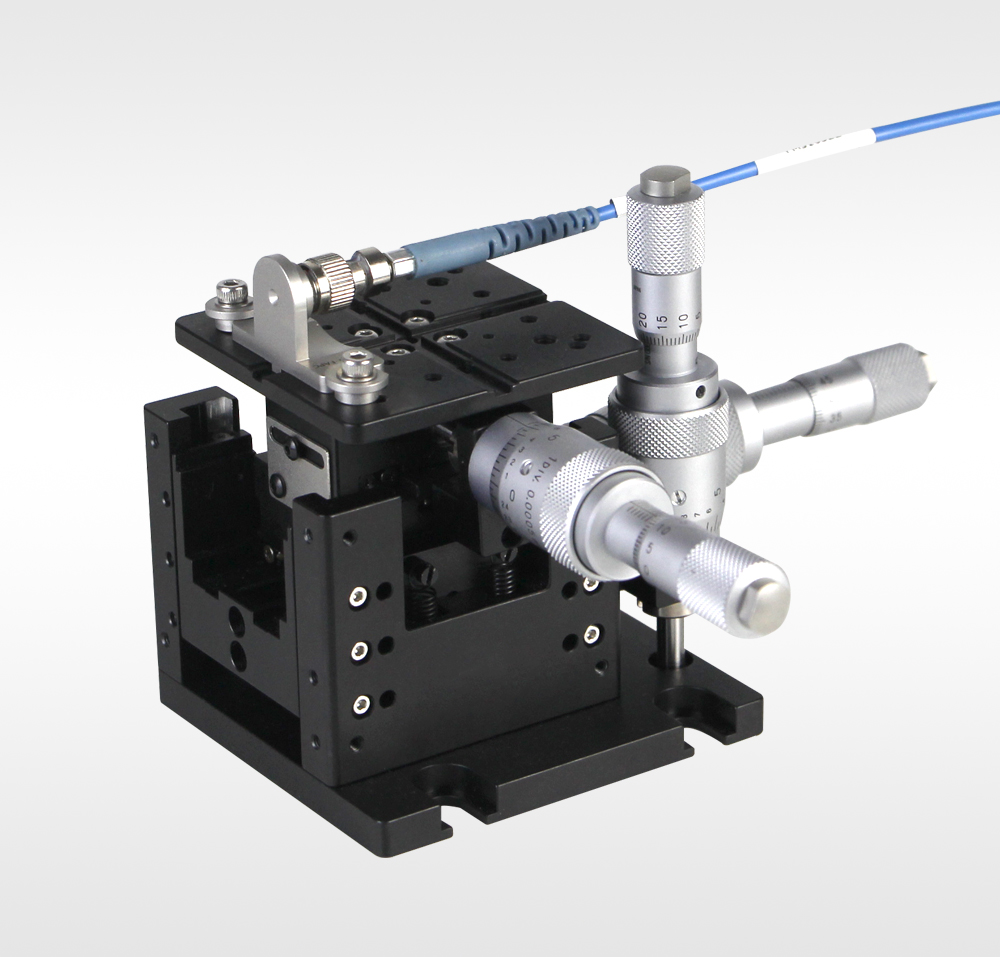

- Suitable for fiber optic coupler systems;

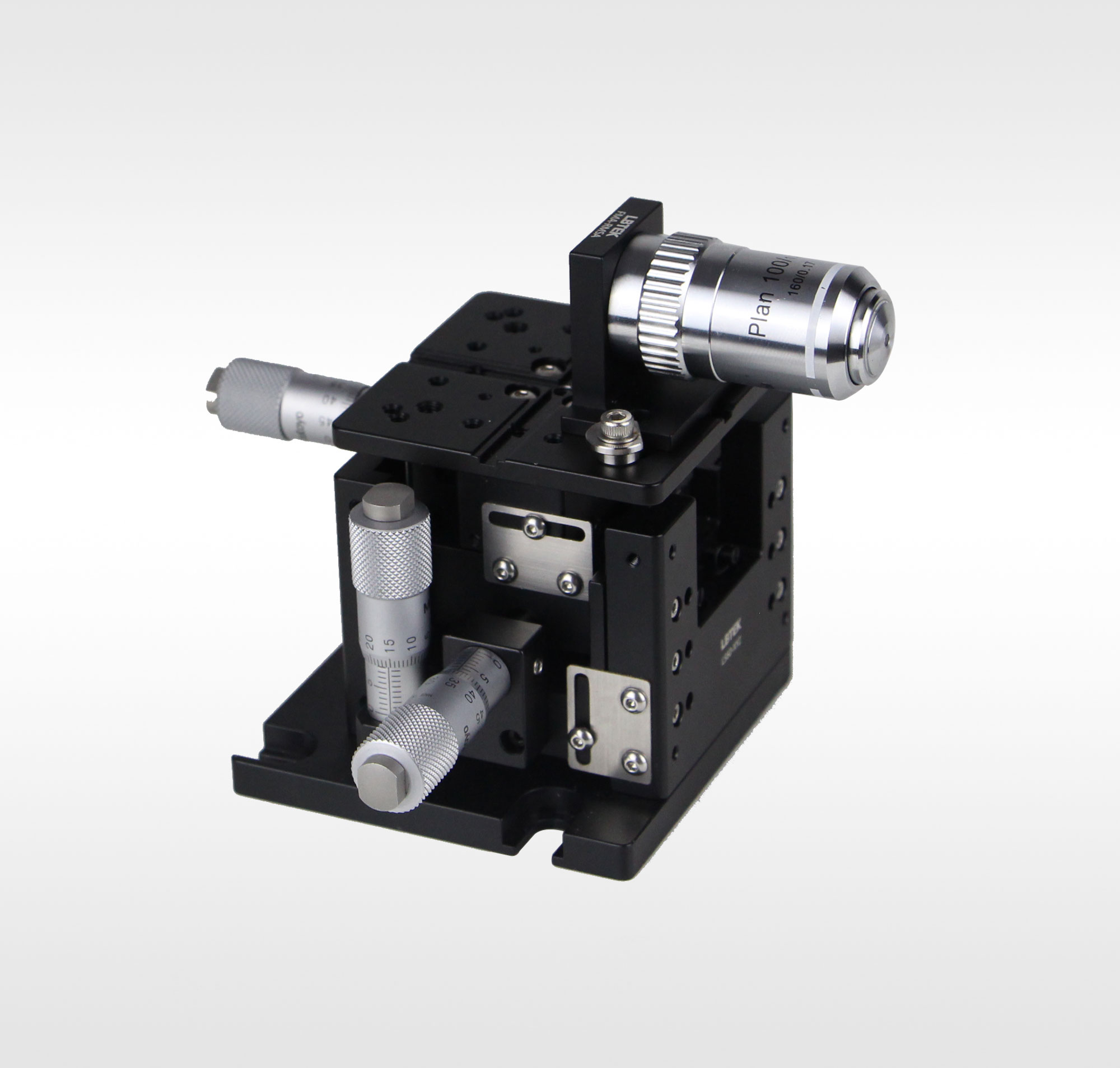

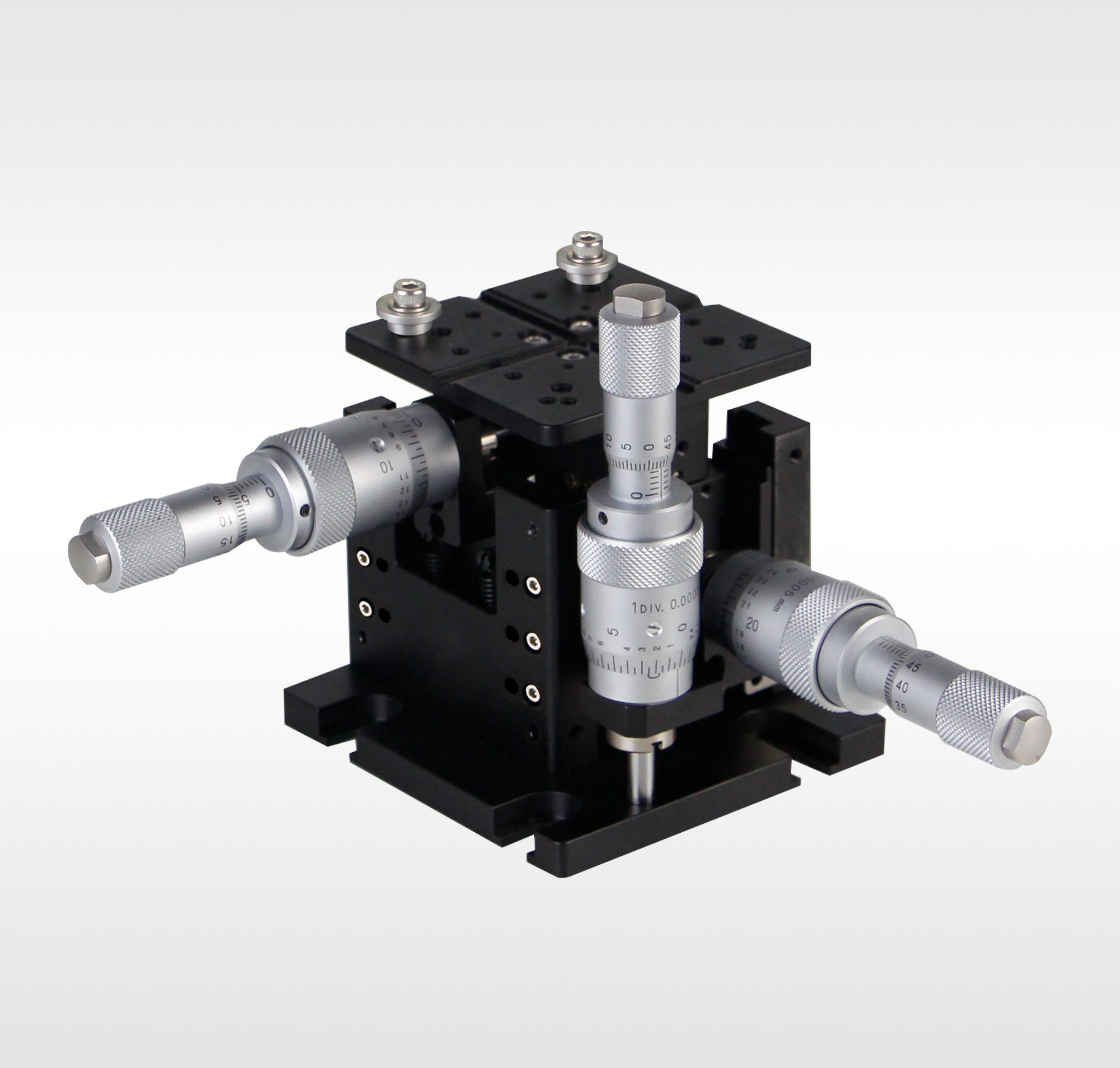

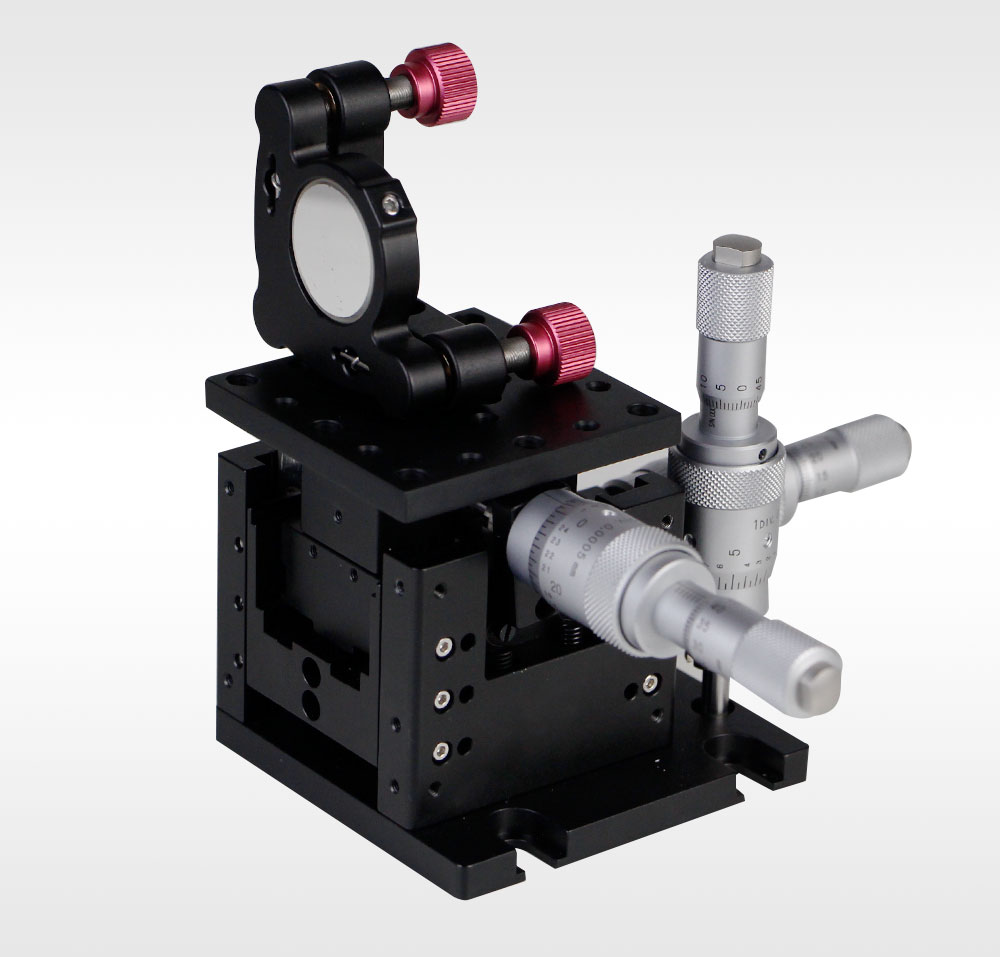

- Cross roller rail structure with high positioning accuracy and large load capacity;

- Driven by Mitutoyo micrometer head for high adjustment resolution;

- Stage size 60 mm × 60 mm;

- X-axis travel 10 mm, Y-axis and Z-axis travel 13 mm;

- Adjustment resolution 10 μm;

The compact three-axis translation stage from LBTEK offers 10 mm travel in the X-axis and 13 mm travel in both Y and Z axes, driven by Mitutoyo micrometer heads with 0.5 mm travel per revolution and a minimum resolution of 10 μm. Featuring a 60 mm×60 mm platform with a central cross groove (3 mm width) for quick accessory alignment, the stage includes M2, M3, and M4 tapped holes for component expansion. Its internal cross-roller rail mechanism ensures high positioning accuracy and rigidity while supporting 3 kg loads. The stage includes side locking screws with two tightening options: hex-key tightening of screws near the micrometers for confined spaces, or using the included three knurled extended-length screws for easier operation in open areas. M6 mounting slots on the base allow installation on optical tables and breadboards.

The objective lens is mounted on the compact three-axis translation stage via the adapter FMA-RMSA.

Product Model | X-axis travel | YZ-axis stroke | Micrometer head minimum scale | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| LS60-XYZ | 10 mm | 13 mm | 10 μm | $1,050.37 | today | Add Cart |

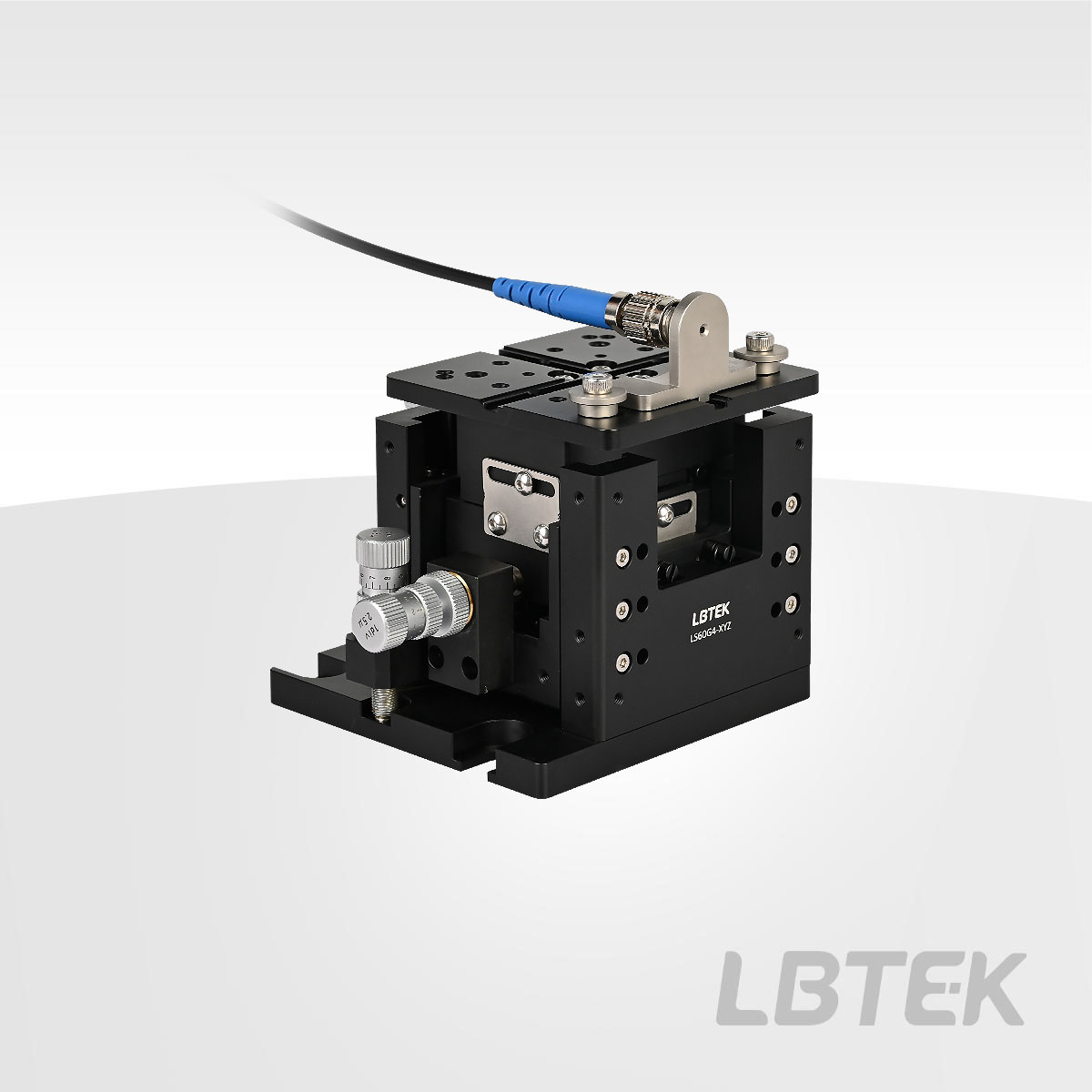

- Table size 60 mm×60 mm

- X-axis, Y-axis, Z-axis travel 4 mm

- Coarse adjustment 0.5mm/rev, fine adjustment resolution 2.5 μm/div

LBTEK compact three-axis translation stage offers 4 mm of travel in the X, Y, and Z axes. It features a miniature drive head with coarse adjustment of 0.5 mm/rev (4 mm travel, no scale lines) and fine adjustment of 0.05 mm/rev (0.25 mm travel, minimum resolution of 2.5 μm/div). The stage surface measures 60 mm × 60 mm and includes a cross groove at the center for quick accessory alignment, with a groove width of 3 mm. It is equipped with M2, M3, and M4 threaded holes for easy expansion with additional components.

The internal guide structure utilizes crossed roller guides, providing high positioning accuracy, high rigidity, and a load capacity of up to 3 kg. Locking screws on the side allow for secure fixation after adjustment. Two locking methods are available: if space is limited, use a hex wrench to tighten the screw next to the micrometer head; if space permits, use the included three extended screws for locking. The provided screws are sufficiently long and feature knurling for easier operation. The base includes M6 mounting holes and slots for installation on optical tables and breadboards.

Note: When using fine adjustment, first lock the coarse adjustment nut, then adjust with the fine adjustment knob. Due to individual differences, an adjustment error within one resolution unit may occur during operation.

Insert the fiber optic patch cord into the fiber optic holder and mount it on the LS60G4-XYZ three-axis displacement stage.

Product Model | XYZ axis stroke | Coarse adjustment micrometer head resolution | Fine-tuning micrometer head resolution | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| LS60G4-XYZ | 4 mm | 0.5 mm/rev | 2.5 μm/div | $1,112.35 | today | Add Cart |

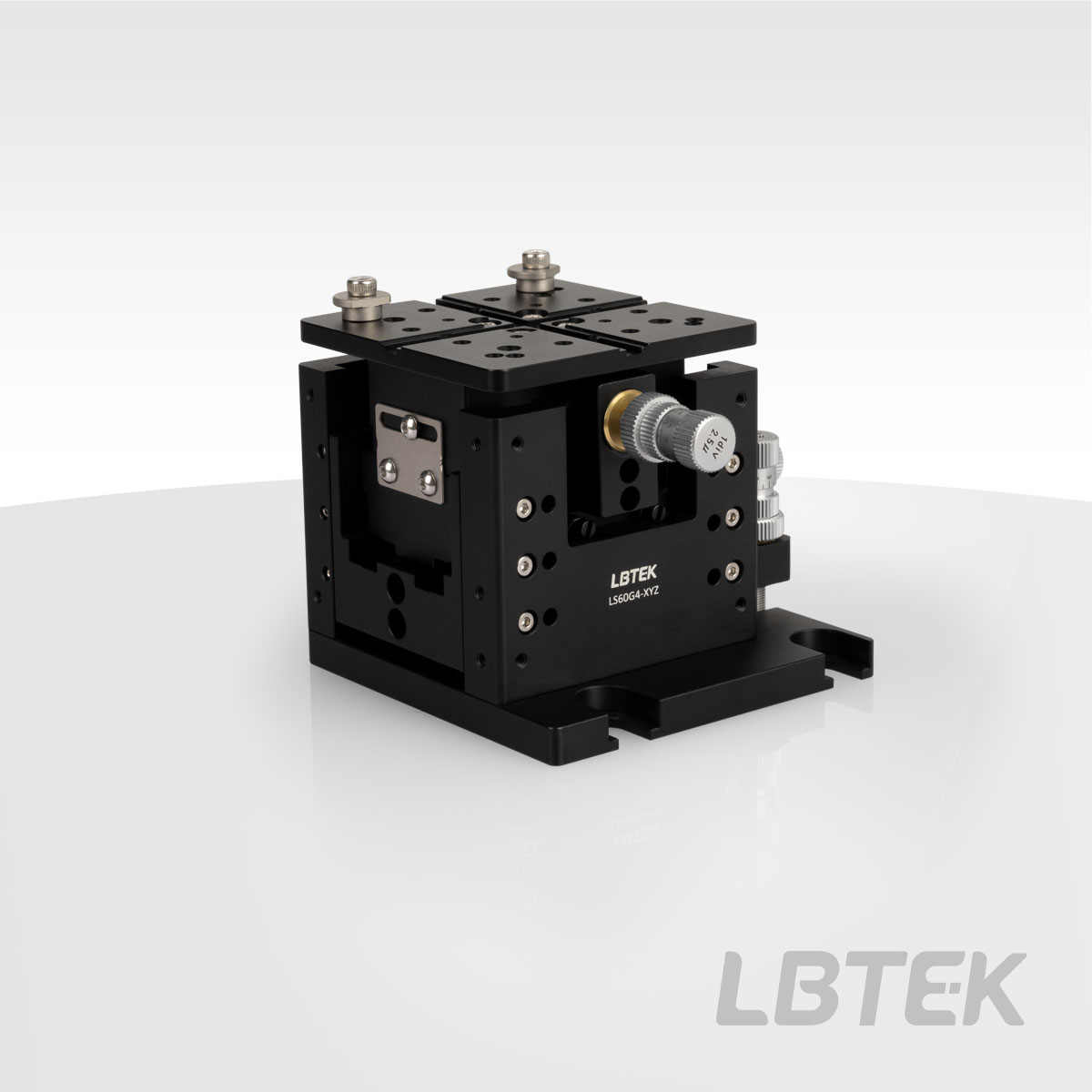

- Table size 60 mm×60 mm

- X-axis, Y-axis, Z-axis travel 13 mm

- Coarse adjustment resolution 10 μm, fine adjustment resolution 0.5 μm

LBTEK Compact Three-Axis Translation Stage offers a travel range of 13 mm in the X, Y, and Z axes, driven by Mitutoyo differential micrometers. The coarse adjustment provides a travel of 0.5 mm per revolution with a resolution of 10 μm, while the fine adjustment offers a travel of 0.025 mm per revolution with a minimum reading (resolution) of 0.0005 mm (0.5 μm). The stage surface measures 60 mm × 60 mm and features a cross groove at the center for quick alignment of accessories, with a groove width of 3 mm. It includes M2, M3, and M4 threaded holes for easy expansion of additional components. The internal guide structure utilizes crossed roller guides, ensuring high positioning accuracy and rigidity while supporting a load of up to 3 kg. Locking screws are provided on the side for securing adjustments, offering two locking methods: if space is limited, use a hex wrench to tighten the screw next to the micrometer; if space permits, use the included three extended screws for locking, which are sufficiently long and feature knurling for easier operation. The bottom is equipped with M6 mounting holes and slots, allowing installation on optical tables and breadboards.

Product Model | XYZ axis stroke | Coarse adjustment micrometer head resolution | Fine-tuning micrometer head resolution | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| LS60G-XYZ | 13 mm | 10 μm | 0.5 μm | $2,473.62 | today | Add Cart |

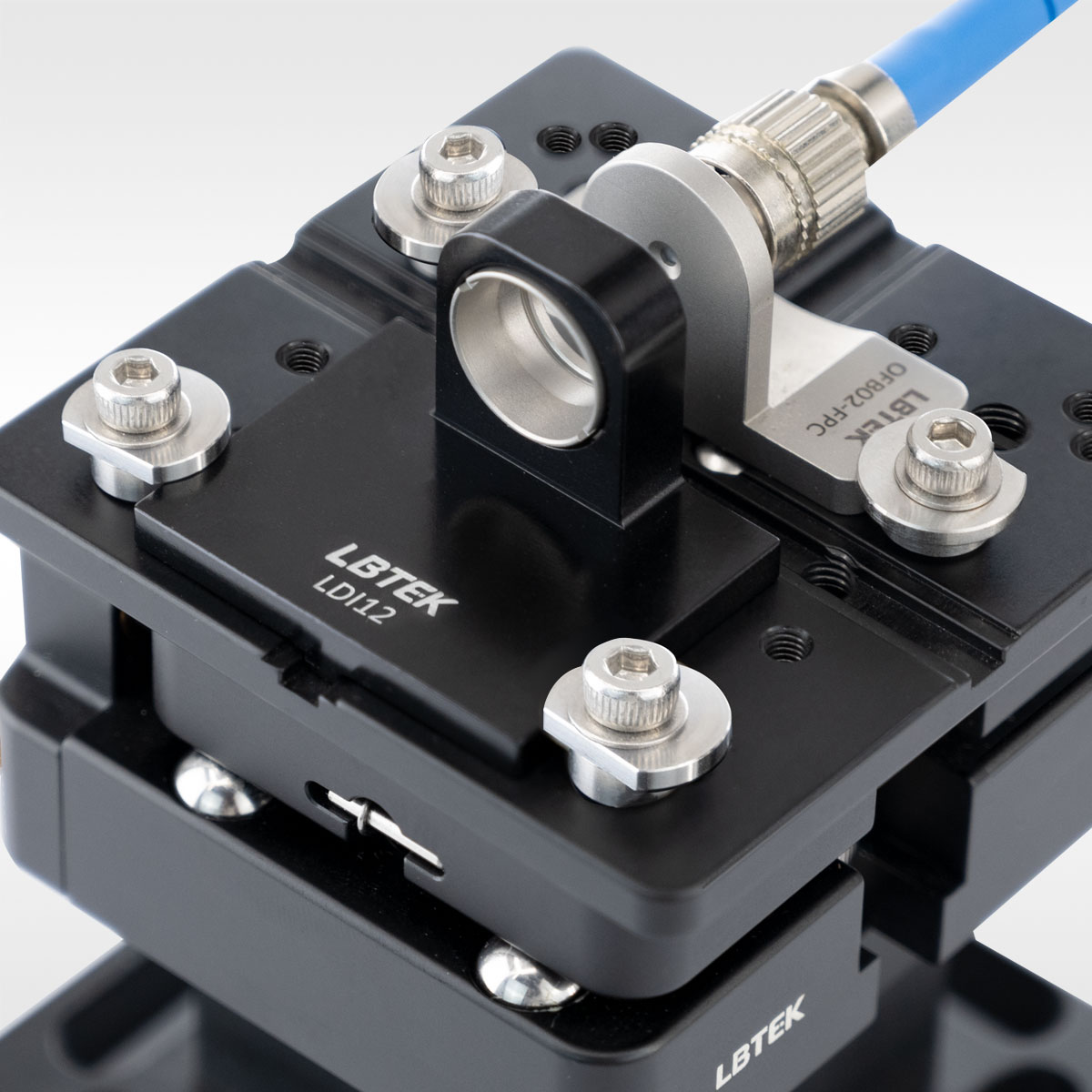

- M8 x 0.5, M9 x 0.5 or M12 x 0.5 female;

- Suitable for molded aspheric lenses;

- Optical axis height 12.5 mm;

The molded aspheric lens mount from LBTEK features female (M8×0.5, M9×0.5, or M12×0.5) for secure aspheric lens installation, with a boss design that aligns with translation stage top plate grooves for rapid positioning. The mount can be secured using optional FF05 retaining clamps and maintains a 12.5 mm optical axis height above the translation stage.

Place the LDI12 and aspheric lens on the PYXYZ five-axis displacement stage along with the OFB02-FPC fiber holder.

Product Model | Thread specification | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| LDI09 | M9 x 0.5 internal thread | $39.88 | today | Add Cart | ||

| LDI12 | M12 x 0.5 internal thread | $39.88 | today | Add Cart | ||

| LDI08 | M8 x 0.5 internal thread | $39.88 | today | Add Cart |

- M8 x 0.5, M9 x 0.5 or M12 x 0.5 female;

- Allowing back-to-back lens mounting;

- Designed for use with molded aspheric lenses;

- Only 6 mm thickness;

- Optical axis height 12.5 mm;

The thin-profile molded aspheric lens mount from LBTEK is an ultra-low-profile mounting solution designed for installing lenses and optical components, featuring female (M8×0.5, M9×0.5, or M12×0.5) to enable back-to-back mounting of molded aspheric lenses. The mount includes a boss compatible with the groove of the translation stage top plate for quick positioning. The mount offers flexible fixation options using either FF05 retaining clamps or AC270M adapter clamping plates, with its optical axis positioned 12.5 mm above the translation stage surface.

The AC270M adjustment plate acts on two thin molded aspheric lens mounts to achieve tight coupling.

Product Model | Thread specification | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| LDI09B | M9 x 0.5 internal thread | $39.88 | today | Add Cart | ||

| LDI12B | M12 x 0.5 internal thread | $39.88 | today | Add Cart | ||

| LDI08B | M8 x 0.5 internal thread | $39.88 | today | Add Cart |

- Working area 60 mm × 60 mm

- Integrated with multiple M4/M3 tapped holes

- Suitable for multi-Axis translation stage

The adapter plate from LBTEK can be used to replace the top plate of a multi-axis translation stage. The AP60-60 adapter plate features numerous M6 and M4 tapped holes, enabling compatibility with a wider range of components on the stage. The M3 countersunk holes enable rapid installation to the stage.

The AP60-60 adapter plate is installed on a multi-axis translation stage.

Product Model | Working area | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| AP60-60 | 60 mm×60 mm | $37.13 | today | Add Cart |