Specifications

Application

Feedback

Product Description

- Point-by-point and layer-by-layer removal

- Minimal heat-affected zone

- Capable of processing arbitrary 2D graphics

- Machine vision

- Integrated system architecture with marble anti-vibration worktable, enhancing operational stability

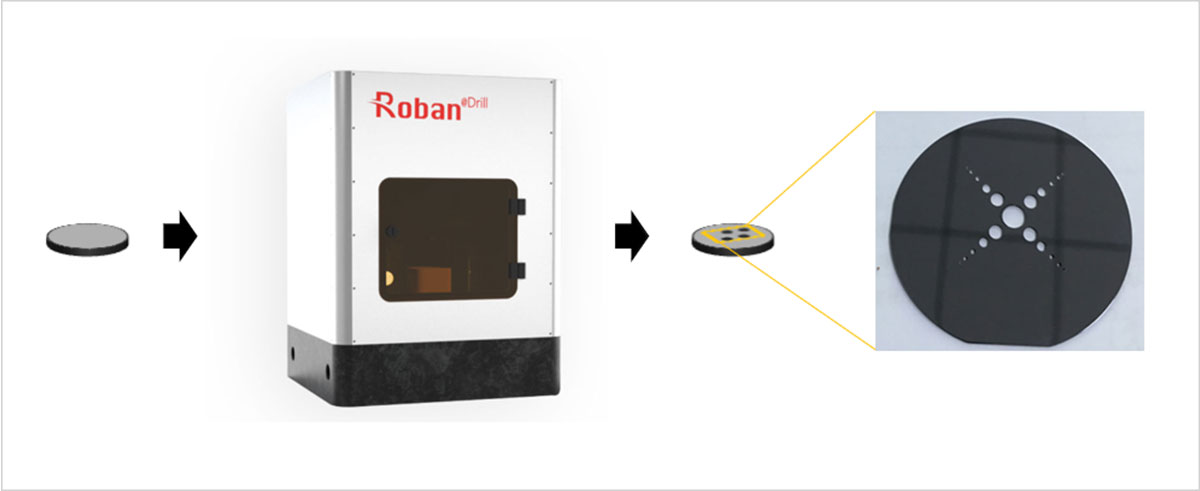

The Roban-Drill series Femtosecond Laser Cutting and Drilling System is equipped with a high-repetition-rate femtosecond laser amplifier (optional), high-speed scanning galvanometer and field lens, as well as a high-precision positioning displacement stage. It is suitable for laboratories in research institutes and corporate R&D centers to conduct high-speed scanning cutting of hard and brittle materials, machining of blind holes, through holes, and cluster holes, and surface grooving of materials. For specific customization details of this system, please contact LBTEK Technical Support.

Diagram

Attributes

light sourceFemtosecond Laser Amplifier (1030 nm / 515 nm, 1-200kHz)

Processing MaterialsSapphire, quartz, silicon wafer, silicon carbide, etc.

Drilled hole diameter20 μm-20mm

Device dimensions (L×W×H)600×500×800 mm

Positioning accuracy±3 μm

Sample thickness0.1 mm-3 mm

Maximum scanning speed200 mm/s

Processing file formatAeroBasic, supports STL format conversion

Electrical RequirementsAC200-240 V,50/60 Hz,5kW