- Compensates for beam offset

- Compatible with 16 mm coaxial systems

- Two options available: X/Y-axis movement and X-axis movement

- X/Y axis displacement travel range ±1.0 mm

- With SM05 internal threaded center hole

- Mounts optical components up to 12.7 mm diameter and 3.8 mm thickness

- Manual adjustment with locking mechanism

Product Model | X/Y-axis stroke | Applicable optical element diameter | Maximum applicable thickness of optical components | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| SP05 | ±1.0 mm | Ø12.7 mm | 2.5 mm | $61.19 | today | Add Cart |

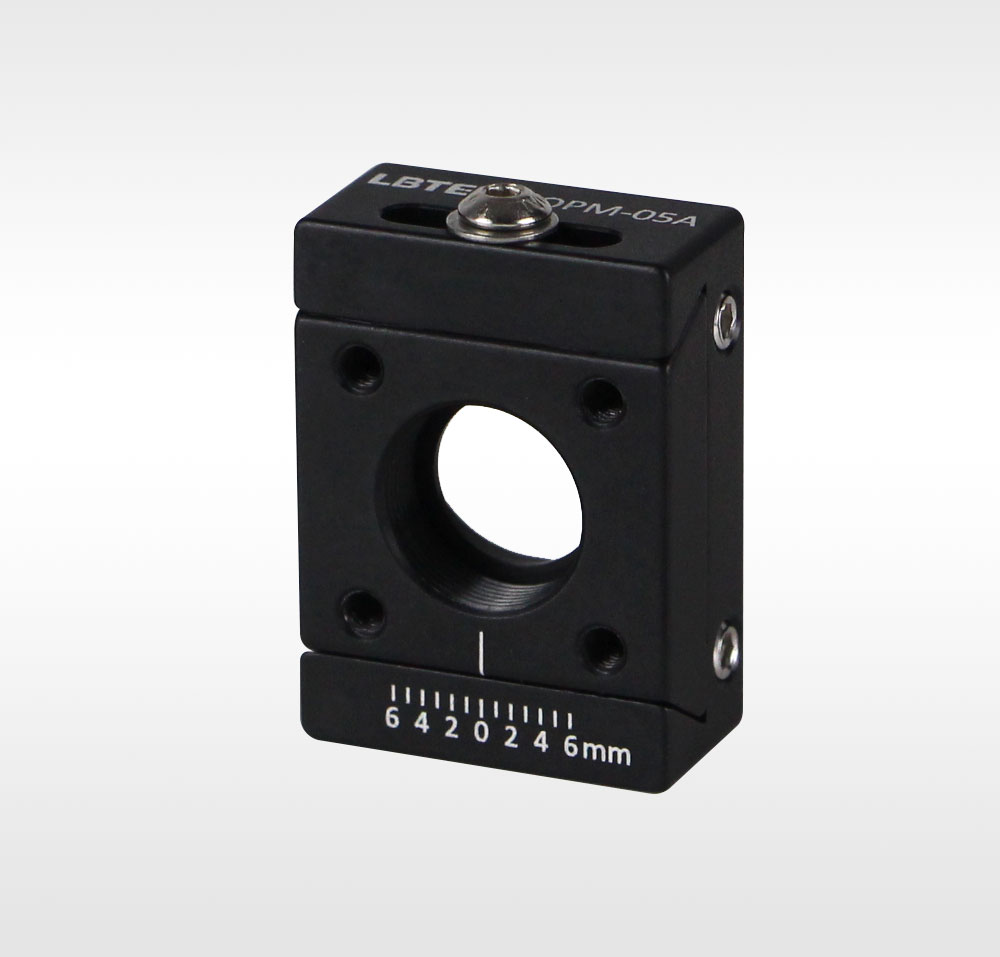

- X-axis displacement travel ±6 mm

- Centered with SM05 thread, includes one SM05R retaining ring

- Accommodates optical components with 12.7 mm diameter and maximum 3.8 mm thickness

- Manual adjustment with locking mechanism

The LBTEK 16 mm coaxial linear translation plate consists of a fixed plate and a movable plate. One plate is designed for mounting on a 16 mm coaxial system or in free space, while the other can be adjusted via a dovetail groove structure with a travel range of ±6 mm. The fixed plate features four coaxial blind holes—installation should not allow coaxial rods to pass through, as they are secured by four M4 set screws on the side. The movable plate includes M3 threaded holes, where coaxial rods are mounted using M3 set screws. The center features an SM05 threaded through-hole, allowing the installation of optical components with a diameter of 12.7 mm and a maximum thickness of 3.8 mm using an SM05R retaining ring. The bottom is equipped with M3 threaded mounting holes for connecting optical rods. The coaxial plate is engraved with ±6 mm scale markings for manual positioning. After adjustment, the position can be locked using the top M3 screw. All adjustments require a 2 mm hex wrench. Note: The two M2.5 ball plunger screws are preload screws and should not be removed, as this may affect the operational feel.

Product Model | X-axis displacement stroke | Applicable optical element diameter | Maximum applicable thickness of optical components | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| SOPM-05A | ±6.0 mm | Ø12.7 mm | 3.8 mm | $101.32 | today | Add Cart |