3D Printing

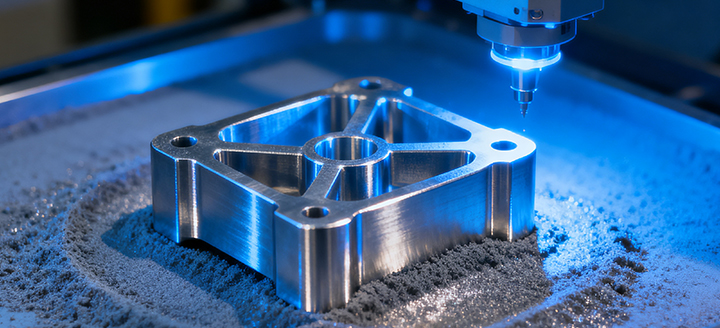

Additive manufacturing (3D printing) is a transformative technology that differs fundamentally from traditional subtractive manufacturing, which shapes materials by removing matter through processes like cutting. Instead, additive manufacturing builds objects layer by layer from the bottom up, converting a three-dimensional entity into a series of two-dimensional planes, thereby significantly reducing manufacturing complexity. As a disruptive innovation relative to conventional subtractive methods, the 3D printing industry is transitioning from its initial phase into a growth stage, showing signs of accelerated expansion.

Compared to traditional subtractive manufacturing, 3D printing offers numerous significant advantages that are unattainable with conventional precision machining, including shortened R&D cycles for new products, the ability to form complex structures, integrated and lightweight design capabilities, high material utilization rates, and excellent mechanical properties. Currently, the adoption of 3D printing is rapidly increasing across various sectors such as aerospace, medical, and automotive industries.

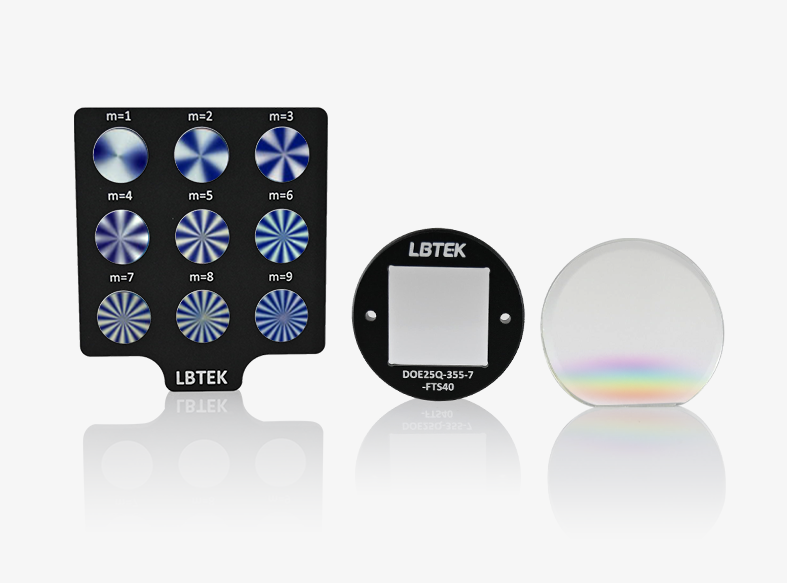

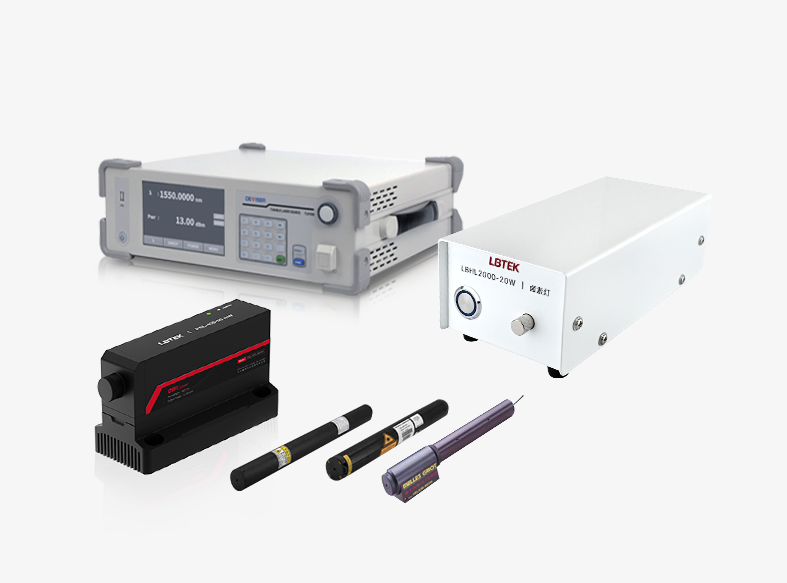

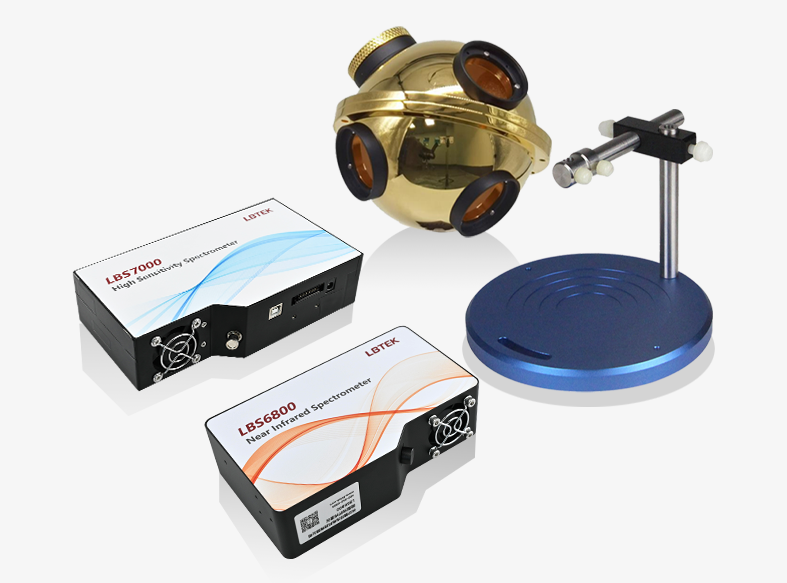

To meet the diverse processing needs of 3D printing in these fields, LBTEK offers a range of beam shaping solutions—including beam splitting, zoom collimators, spot-ring DOEs, Bessel beams, and homogenization—which are applied in the selective laser melting process, one of the key laser powder bed fusion technologies. These solutions address critical challenges such as processing efficiency, variability in build size, spatter during manufacturing, achieving higher resolution, and warping due to temperature gradients.

In addition, LBTEK designs and develops supporting optical components—including beam expanders, fixed and zoom collimators, field lenses, mirrors, lenses, annular DOEs, axicons, and waveplates—to maximize the benefits that shaped laser beams bring to additive manufacturing processes.