- OD value can be adjusted by rotating the filter angle

- Circular shape, OD value continuously adjustable

- Anti-reflection coating: 650-1050 nm

- Installed in a mechanical housing with scale

- Coating: Inconel & anti-reflection coating

- Dimensions: Ø25 mm, Ø50 mm, or Ø100 mm

- OD range: 0.02-2.0, 0.02-4.0, 0.02-6.0

LBTEK's mechanical housing for installed continuous neutral density filters features angular scales and a rotation axis. The mount is precisely designed to minimize the impact on the optical element's clear aperture. The continuous neutral density filter is coated with a filtering film (Inconel film) on one side and an anti-reflection coating (B-coating) on the other. The side with the scale is the filtering film side, and for optimal performance, it is recommended to have light incident from this side. Although it is a reflective neutral density filter, the Inconel film still absorbs some incident light. Additionally, this unprotected metal film should be handled with care to avoid contact; cleaning is recommended using an air blower.

Continuous Neutral Density Filter Assembly with Installation

Product Model | Filter outer diameter | OD value range | Filter thickness | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| NDFR-25C-2M-B | Ø25 mm | 0.02a-2.0 | 2.0 mm | $450.14 | today | Add Cart | ||

| NDFR-25C-4M-B | Ø25 mm | 0.02a-4.0 | 2.0 mm | $450.14 | today | Add Cart | ||

| NDFR-25C-6M-B | Ø25 mm | 0.02a-6.0 | 2.0 mm | $491.98 | 6 weeks | Add Cart | ||

| NDFR-50C-2M-B | Ø50 mm | 0.02a-2.0 | 2.0 mm | $479.56 | today | Add Cart | ||

| NDFR-50C-4M-B | Ø50 mm | 0.02a-4.0 | 2.0 mm | $479.56 | today | Add Cart | ||

| NDFR-50C-6M-B | Ø50 mm | 0.02a-6.0 | 2.0 mm | $556.83 | today | Add Cart | ||

| NDFR-100C-2M-B | Ø100 mm | 0.02a-2.0 | 2.0 mm | $651.35 | today | Add Cart | ||

| NDFR-100C-4M-B New | Ø100 mm | 0.02a-4.0 | 2.0 mm | $651.35 | Contact | Add Cart | ||

| NDFR-100C-6M-B New | Ø100 mm | 0.02a-6.0 | 2.0 mm | $741.83 | today | Add Cart |

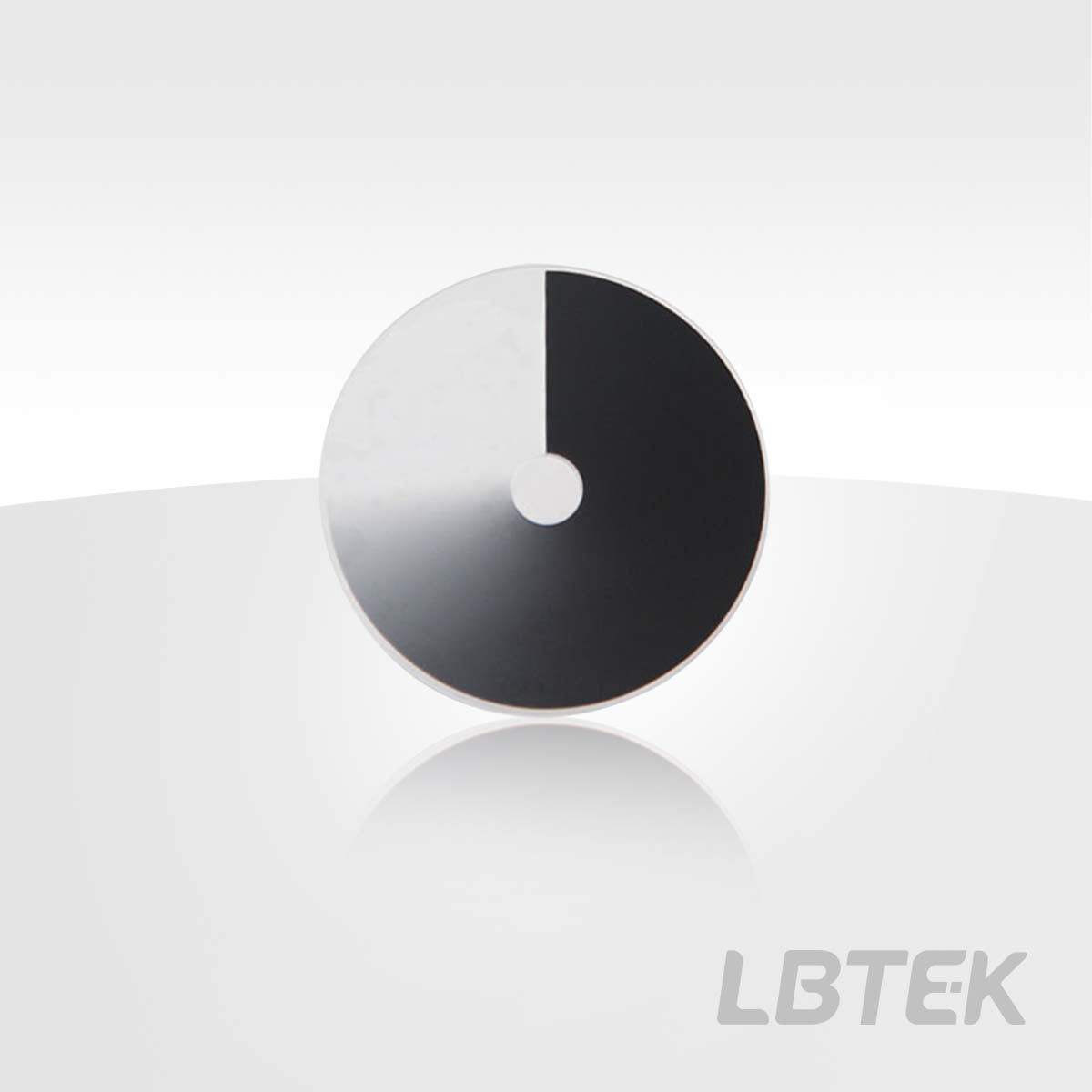

- Not installed

- Coating: Inconel & Anti-reflection coating

- Size: Ø25 mm, Ø50 mm or Ø100 mm

- OD range: 0.02-2.0, 0.02-4.0, 0.02-6.0

LBTEK uninstalled continuous neutral density filters feature a central hole diameter of 7.5 mm, facilitating mechanical mounting. The OD value of the continuous neutral density filter can be adjusted by rotation. One side of the continuous neutral density filter is coated with a filter film (Inconel film), while the other side is coated with an anti-reflection coating (B-coating). For optimal performance, it is recommended that light enters from the filter film side. Although it is a reflective neutral density filter, the Inconel film still absorbs a portion of the incident light. Additionally, this unprotected metal film should be handled with care to avoid contact; cleaning is recommended using an air blower.

Continuous Neutral Density Filter Assembly Not Installed

Product Model | Filter outer diameter | OD value range | Filter thickness | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| NDFR-25C-2-B | Ø25 mm | 0.02a-2.0 | 2.0 mm | $352.48 | today | Add Cart | ||

| NDFR-25C-4-B | Ø25 mm | 0.02a-4.0 | 2.0 mm | $352.48 | today | Add Cart | ||

| NDFR-25C-6-B | Ø25 mm | 0.02a-6.0 | 2.0 mm | $403.60 | today | Add Cart | ||

| NDFR-50C-2-B | Ø50 mm | 0.02a-2.0 | 2.0 mm | $376.67 | today | Add Cart | ||

| NDFR-50C-4-B | Ø50 mm | 0.02a-4.0 | 2.0 mm | $376.67 | today | Add Cart | ||

| NDFR-50C-6-B | Ø50 mm | 0.02a-6.0 | 2.0 mm | $454.85 | today | Add Cart | ||

| NDFR-100C-2-B | Ø100 mm | 0.02a-2.0 | 2.0 mm | $426.09 | today | Add Cart | ||

| NDFR-100C-4-B | Ø100 mm | 0.02a-4.0 | 2.0 mm | $426.09 | Contact | Add Cart | ||

| NDFR-100C-6-B | Ø100 mm | 0.02a-6.0 | 2.0 mm | $530.94 | today | Add Cart |

- M6 threaded hole on the main body, with M4 threaded hole adapter included

- Compatible with NDFR series filters with center hole diameter Ø7.5 mm

- Suitable for optical elements with a thickness of 2 mm

The LBTEK Neutral Density Filter Mount allows the installation of NDFR series filters with a central hole diameter of Ø7.5 mm onto the rotating shaft. To install the filter, first use the included 1.5 mm hex wrench to tighten the fixing screw on the side of the NDFR-PM to lock the rotation. Then, use the included 2 mm hex wrench to remove the silver hex socket screw. Place the filter between the two washers, then reassemble the rotating wheel and screw combination. Please note to maintain the original sequence of flat washers and wave springs when reassembling, and securely fasten the bolt. The package includes one each of 1.5 mm and 2.0 mm hex wrenches.

Product Model | Applicable Optical Component Center Hole Diameter | Applicable optical element thickness | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| NDFR-PM | Ø7.5 mm | 2 mm | $52.43 | 4 weeks | Add Cart |