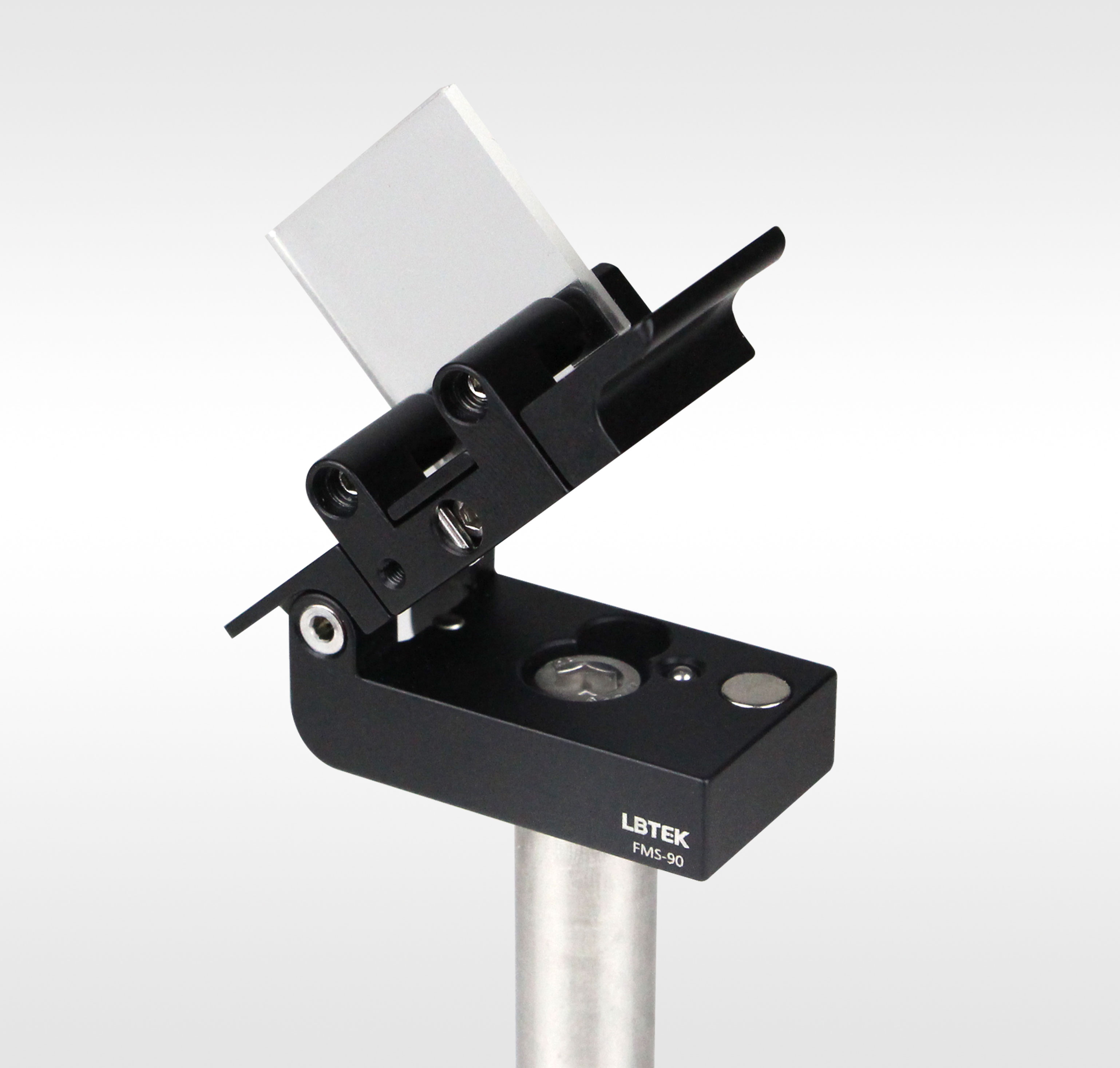

- 90° flipping/restoration can achieve avoidance of the light path or return to the light path

- Good repeatability for flipping or restoration

- Top thread specification: three M4 threaded holes, one M4 countersunk smooth bore in the center

- Bottom thread specification: one M4 countersunk smooth bore

- 90° flip design to avoid light path interference

- Suitable for mounting round or rectangular optical components

- Maximum applicable optical component thickness: 6 mm

- M4 and M6 countersunk mounting holes

The LBTEK 90° Flip Mount is designed for mounting round optical components up to Ø25.4 mm with a maximum thickness of 6 mm or rectangular optical components ranging in size from 24 mm × 10 mm to 50 mm × 50 mm. The mount secures the optical component via clamping with two rubber-tipped screws to prevent scratches. The pivot structure allows the mount to be fixed at nearly any angle between 0° and 90°, with magnets at the 0° and 90° positions providing additional securing force. The bottom features M4 and M6 countersunk holes for mounting the flip mount onto posts. The pivot structure consists of one screw and two ball contacts, which are factory-set and require no user adjustment. Note: The magnet at the 0° position slightly pulls the mount to close at a minimal angle. At the 0° position, the angular repeatability is less than 25 µrad.

Product Model | Tilting angle | Material | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| FMS-90 | 90° | 6061-T6 aluminum alloy | $75.31 | today | Add Cart |

- 90° flip design to avoid light path

- Repeatable flip design

- With M4 mounting holes

The LBTEK 90° Flip Mount Adapter is commonly used for comparative experiments. Its 90° flip design allows the mounted optical components to avoid the light path, and repeated flipping can still return to the original position. The top surface of the flip mount features three M4 threaded holes and one M4 countersunk hole, where an M4 hex socket cap screw can be inserted from below. The bottom includes an M4 countersunk mounting hole for connecting to a standard Ø12.7 mm optical post. Purchasing the LBTEK flip mount also includes two complimentary M4×8 hex socket cap screws. The LBTEK flip mount undergoes rigorous repeatability testing, ensuring flip repeatability within 20 urad in both the X and Y directions.

The 90° flip design allows it to avoid the light path.

Product Model | Tilting angle | Thread hole specifications | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| TM90 | 90° | M4 | $49.81 | today | Add Cart |