- 360° continuous rotation;

- Platform tapped holes are compatible with standard optomechanics;

- The side has an M4 or M6 tapped hole for direct mounting of Ø12.7 mm optical posts;

- High-precision manual rotary translation stages RP-1A-KIT and RP-1A are available for sale;

- Continuous 360° rotation;

- Rotating disk side markings have an accuracy of 2°;

- Platform tapped holes: M6 (1 piece), M3 (6 pieces);

- Mounting for fiber optic components;

- Four M6 through-holes for mounting to optical tables or breadboards;

The RP-2B manual rotary translation stage from LBTEK features a Ø1-inch rotary stage designed for mounting small optomechanics. This displacement stage provides 360° continuous rotation, with circumferential graduations at 2° intervals and numerical markings at 30° increments. The stage surface includes six M3 tapped mounting holes, one M6 tapped hole, and two Ø3.2 mm holes for fiber component installation. After fiber component installation, M3 screws are used to laterally secure components.

1-inch Manual Rotary Stage for Mounting Free Space Isolators.

Product Model | Rotation angle | Scale division resolution( | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| RP-2B | 360° continuous | 2° | $82.89 | today | Add Cart |

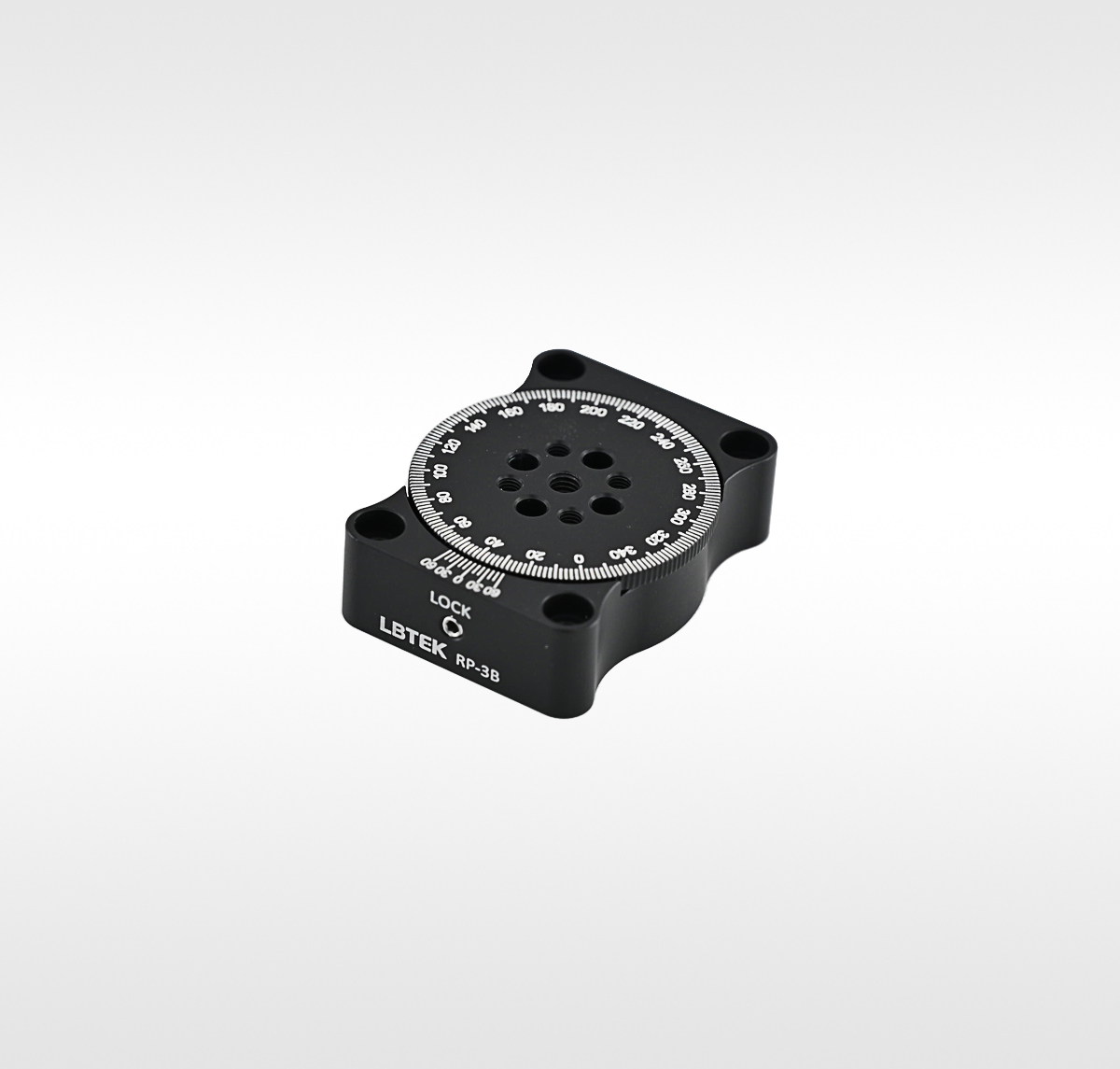

- 360° continuous rotation;

- The scale lines on the side of the rotating disk have an accuracy of 2°, with difference scale lines accurate to 10′;

- Platform tapped holes: M4 (1 piece), M3 (4 pieces), M3 countersunk mounting holes (4 pieces);

- Four M3 through-holes for mounting to optical tables or breadboards;

The RP-3B manual mini series rotary translation stage from LBTEK features a Ø1.4 inch rotary stage. The displacement stage achieves 360°continuous rotation, with the outer circumference of stage graduated at 2° intervals with difference graduation lines to achieve an accuracy of 10′. Locking is controlled by a lateral rubber-tipped screw. The rotating platform surface includes four M3 tapped holes, one M4 tapped hole, and four M3 countersunk holes. The base contains four M3 countersunk holes for mounting micro dovetail translation stages. The side contains one M3 mounting hole enabling vertical installation of the translation stage.

The micro dovetail translation stage is mounted on a manual rotary translation stage.

Product Model | Rotation angle | Scale division resolution( | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| RP-3B | 360° continuous | 2° | $75.83 | today | Add Cart |

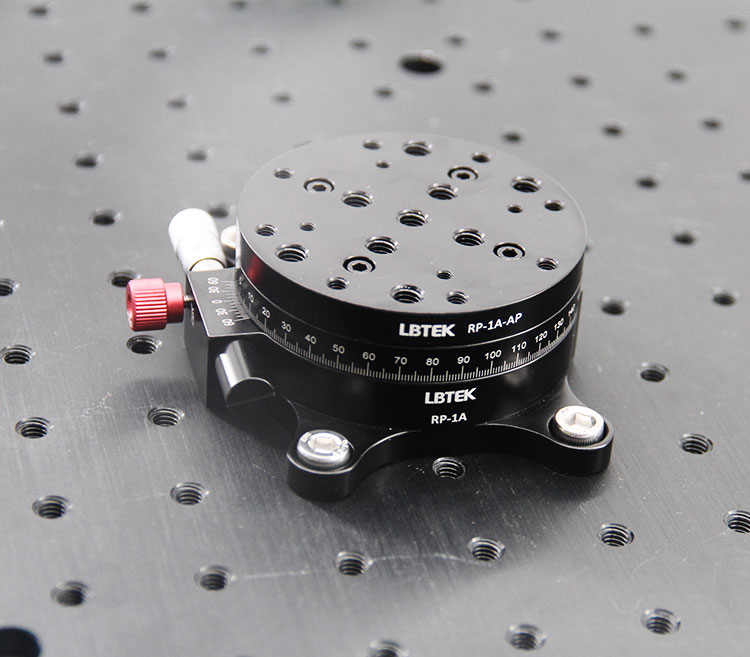

- 360° continuous rotation;

- The side scale of the rotating disk has a precision of 1°, with difference scale markings at 5′;

- Micrometer screw with 10 main divisions and 50 sub-divisions, enabling precise adjustment of the rotating platform within ±5°, with an adjustment precision of 1.2′ (0.02°);

- Equipped with a coarse/fine adjustment toggle lock and a fine adjustment locking knob;

- An lateral M6 tapped hole for mounting posts;

- Component assembly of RP-1A and RP-1A-AP;

- The platform surface features standard M6, M4, and M3 tapped hole arrays for mounting standard optomechanics, clamping arms, or posts for 30 mm coaxial systems;

The manual rotary translation stage kit RP-1A-KIT from LBTEK, assembled from rotary stage RP-1A and adapter plate RP-1A-AP, delivers 360° continuous rotation. The rotating disk's circumferential scale has 1° graduation intervals with vernier markings achieving 5′ accuracy. A lateral thumb screw enables coarse/fine adjustment switching: loosening the thumb screw permits manual coarse rotation, while tightening it locks coarse motion and engages micrometer fine adjustment. The micrometer screw has 10 main scale divisions corresponding to a ±5° rotation adjustment range and 50 vernier subdivisions corresponding to an accuracy of 60′/50 = 1.2′ (0.02°), and can be locked by its adjacent thumb screw. Simultaneously locking both the rotating disk's lateral thumb screw and the micrometer's adjacent thumb screw secures the entire rotating platform. The rotating disk features M6, M4, M3 tapped hole arrays for same-thread components, prism mount clamping arms, and 30mm coaxial system posts. Base countersunk tapped holes are used to install the rotary stage on M6-tapped optical tables or breadboards. The lateral M6 tapped hole accepts Ø 12.7 mm optical posts. Components RP-1A and RP-1A-AP are available separately.

Product Model | Coarse adjustment rotation range | Minimum precision of coarse adjustment scale | Minimum resolution of micrometer fine adjustment | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| RP-1A-KIT | 360° continuous | 1° | 0.02° | $243.44 | today | Add Cart |

- 360° continuous rotation;

- The side scale of the rotating disk has a precision of 1°, with difference scale markings at 5′;

- Micrometer screw with 10 main divisions and 50 sub-divisions, enabling precise adjustment of the rotation platform within ±5°, with an adjustment precision of 1.2′ (0.02°);

- Equipped with a coarse/fine adjustment toggle lock and a fine adjustment locking knob;

- An lateral M6 tapped hole for mounting posts;

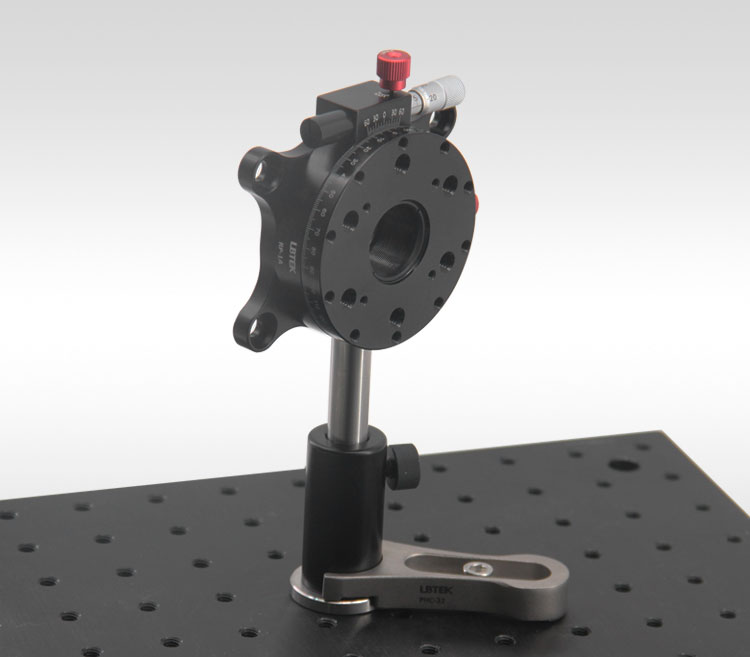

- The center of the rotating platform features an SM1 screw thread and includes an SM1R retaining ring for standard Ø25.4 mm optical components installation;

- The platform surface features standard M6, M4, and M3 tapped hole arrays for mounting standard optomechanics, clamping arms, or posts for 30 mm coaxial systems;

The manual rotary translation stage RP-1A from LBTEK achieves 360° continuous rotation. The rotating disk's circumferential scale has 1° graduation intervals with vernier markings achieving 5′ accuracy. A lateral thumb screw enables coarse/fine adjustment switching: loosening the thumb screw permits manual coarse rotation, while tightening the thumb screw locks coarse motion and engages micrometer fine adjustment. The micrometer screw has 10 main scale divisions corresponding to a ±5° rotation adjustment range and 50 vernier subdivisions corresponding to an accuracy of 60′/50 = 1.2′ (0.02°), and can be locked by its adjacent thumb screw. Simultaneously locking both the rotating disk's lateral thumb screw and the micrometer's adjacent thumb screw secures the entire rotating platform. The rotating disk features M6, M4, M3 tapped hole arrays for same-thread components, prism mount clamping arms, and 30mm coaxial system posts. Base countersunk tapped holes are used to install the rotary stage on M6-tapped optical tables or breadboards. The lateral M6 tapped hole accepts Ø 12.7 mm optical posts. The rotary stage center has an SM1 screw thread and comes with an SM1R retaining ring that can accommodate standard Ø 25.4mm optical components or SM1 lens tubes.

RP-1A vertical mounting on optical stage.

Product Model | Rotation angle range | Minimum precision of coarse adjustment scale | Minimum resolution of micrometer fine adjustment | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| RP-1A | 360° continuous | 1° | 0.02° | $217.55 | today | Add Cart |

- 6061-T6 Aluminum Alloy

- Black Anodized

- Dimensions: Ø68.5 mm

- Thickness: 7.6 mm

- M3 Socket Head Cap Screw ×4

The solid adapter plate RP-1A-AP from LBTEK is primarily used for adaption, assembling with the RP-1A into the RP-1A-KIT. The plate's surface rotating disk features arrays of M6, M4, and M3 tapped holes, enabling flexible installation of post holders, clamping arms, and 30 mm coaxial systems.

Product Model | Tabletop size | Thickness | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| RP-1A-AP | Ø68.5 mm | 7.6 mm | $26.28 | today | Add Cart |

- For 360° continuous rotation with 30 mm coaxial systems;

- Adapter-enabled transfer of preassembled 30 mm coaxial system components to rotary translation stage RP-1A;

- Single-screw clamping mechanism;

- M3 socket head cap screw ×4;

The 30mm coaxial system rotary adapter from LBTEK connects 30mm coaxial structures to the RP-1A rotary translation stage, enabling precise cage system alignment via the micrometer head of stage. This adapter secures to the RP-1A with four M3 socket head cap screws while its single-screw clamping mechanism simultaneously grips dual 30mm coaxial cage rods. Pre-assembled coaxial systems mount directly onto the adapter's clamp-type components without disassembly. The purchase comes with M3 socket head cap screws.

The coaxial system mounts to rotary translation stage RP-1A using RAM30.

Product Model | Size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|

| RAM30 | Ø65.8 mm×27.8 mm | $82.37 | today | Add Cart |

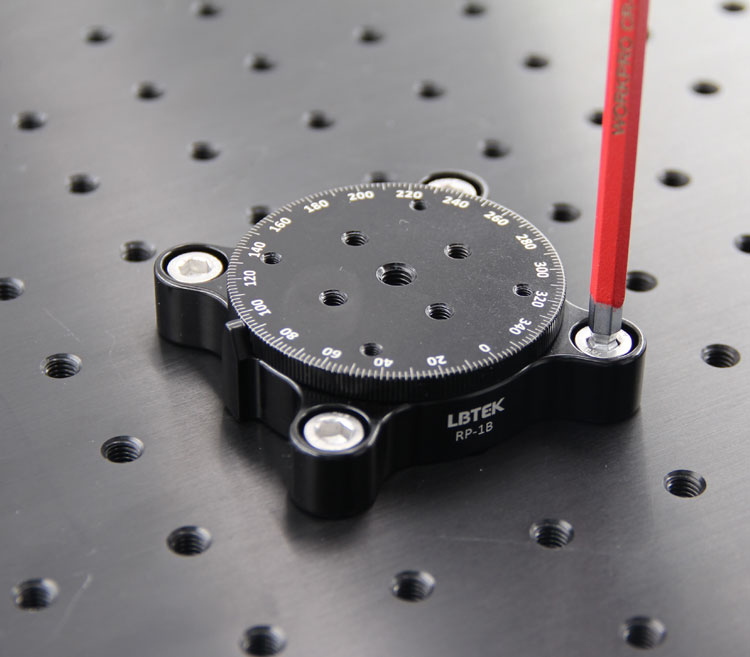

- 360° continuous rotation with 2° graduation resolution;

- Rotation can be locked via fixing screw;

- Platform tapped holes: M6 (1 piece), M4 (4 pieces), M3 (4 pieces);

- Compatible with 30 mm coaxial systems;

- One side M4 tapped hole for connecting Ø12.7 mm optical posts;

The LBTEK manual rotary translation stage for high-load vertical mounting, RP-1B, from LBTEK features a Ø56mm stage. Its rotary disk features M6, M4, and M3 tapped hole arrays for mounting same-thread components, prism mount clamping arms, and 30 mm coaxial system posts. The base contains countersunk tapped holes for horizontal installation of rotary stage on optical stage/breadboards using the included M6x16 socket head cap screw. An additional lateral M4 tapped hole enables vertical mounting on Ø12.7mm posts. The rotary stage is locked via a side M4 setscrew (2mm hex key operated).

Product Model | Rotation angle | Scale division resolution( | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| RP-1B | 360° continuous | 2° | $96.62 | today | Add Cart |