Specifications

Curve

Tutorial

Assembly

Application

Customization

Feedback

Product Description

- For laser beam homogenization and shaping

- Polarization-dependent, the right-handed or left-handed circularly polarized component in the incident beam diverges or converges after passing through the microlens unit, and the outgoing circular polarization state is opposite to the incident circular polarization state

- Planar device, based on diffraction principle

- Single wavelength, free from spherical aberration

- Various customization services

The LBTEK flat microlens array is a planar optical element based on the diffraction optics principle of liquid crystal polymers, designed for laser beam homogenization and shaping. It consists of a polymer film and a single N-BK7 window plate, utilizing the arrayed phase distribution on the liquid crystal polymer film to achieve microlens array functionality. The output beam profile is related to various parameters of the microlens units. By adjusting the phase period and contour of the microlens units, the divergence angle and spot shape of the output beam can be flexibly controlled, meeting diverse requirements for laser beam homogenization and shaping with various shapes and sizes.

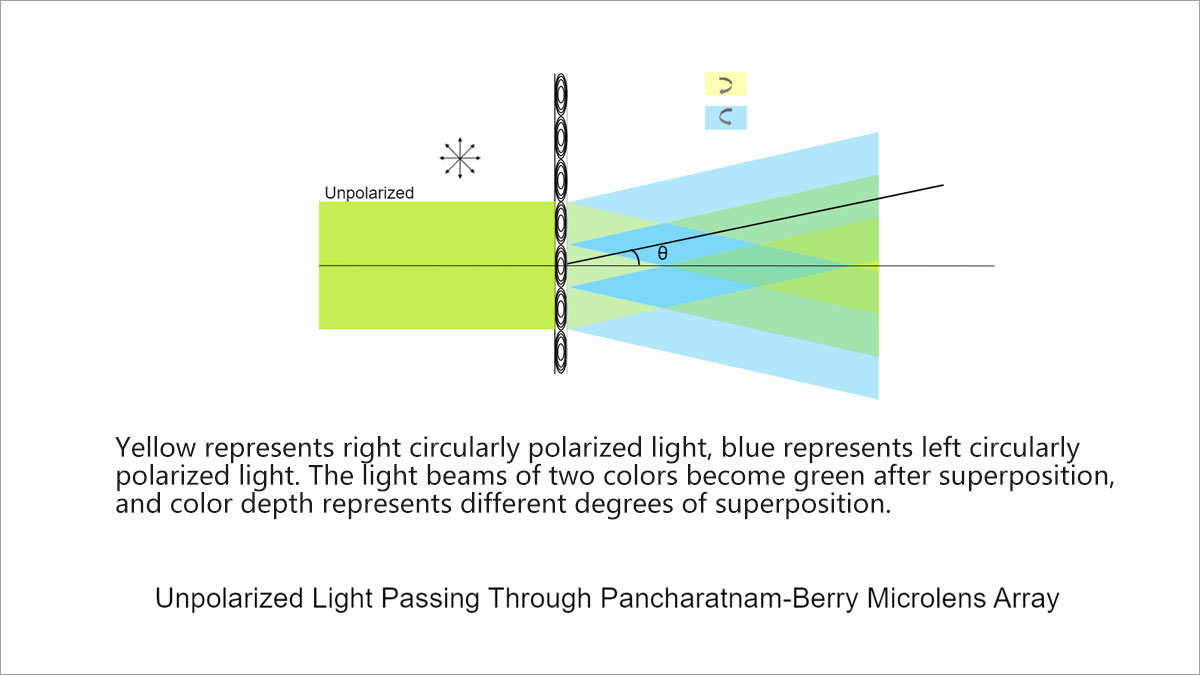

This device is polarization-dependent. By controlling the incident light to be right-handed or left-handed circularly polarized, the beam can be diverged or converged after passing through the unit lens. Based on the diffraction principle, the divergence or convergence angle of the unit lens follows sinθ = λ/p, where λ is the design wavelength and p is the radial phase period of the single lens. Additionally, the microlens array is designed for a single wavelength, free from spherical aberration, and features an anti-reflection coating on the incident surface, ensuring high transmittance and diffraction efficiency.

It finds broad applications in various systems such as wavefront sensing, optical energy concentration, and beam shaping, with significant potential in fields like optical information processing, optical interconnects, optical computing, image scanners, light-field cameras, medical devices, 3D imaging and display.

LBTEK offers standard microlens arrays with a size of Ø25.4 mm, microlens unit focal lengths of 5 mm and 50 mm, square output beam shapes, and operating wavelengths of 532 nm, 633 nm, 850 nm, 915 nm, and 976 nm. Furthermore, LBTEK also provides customized services for special specifications, including unique sizes, operating wavelengths, beam divergence angles, and beam profiles. For specific customization needs, please contact LBTEK Technical Support.

Diagram

Attributes

Optical component materialLiquid Crystal Polymer/N-BK7 Window Plate

Optical element diameterØ25.4 mm

Thickness1.6 mm

Clear ApertureØ21.5 mm

Surface finish (scratches/pits)60/40

Flat Microlens Arrays

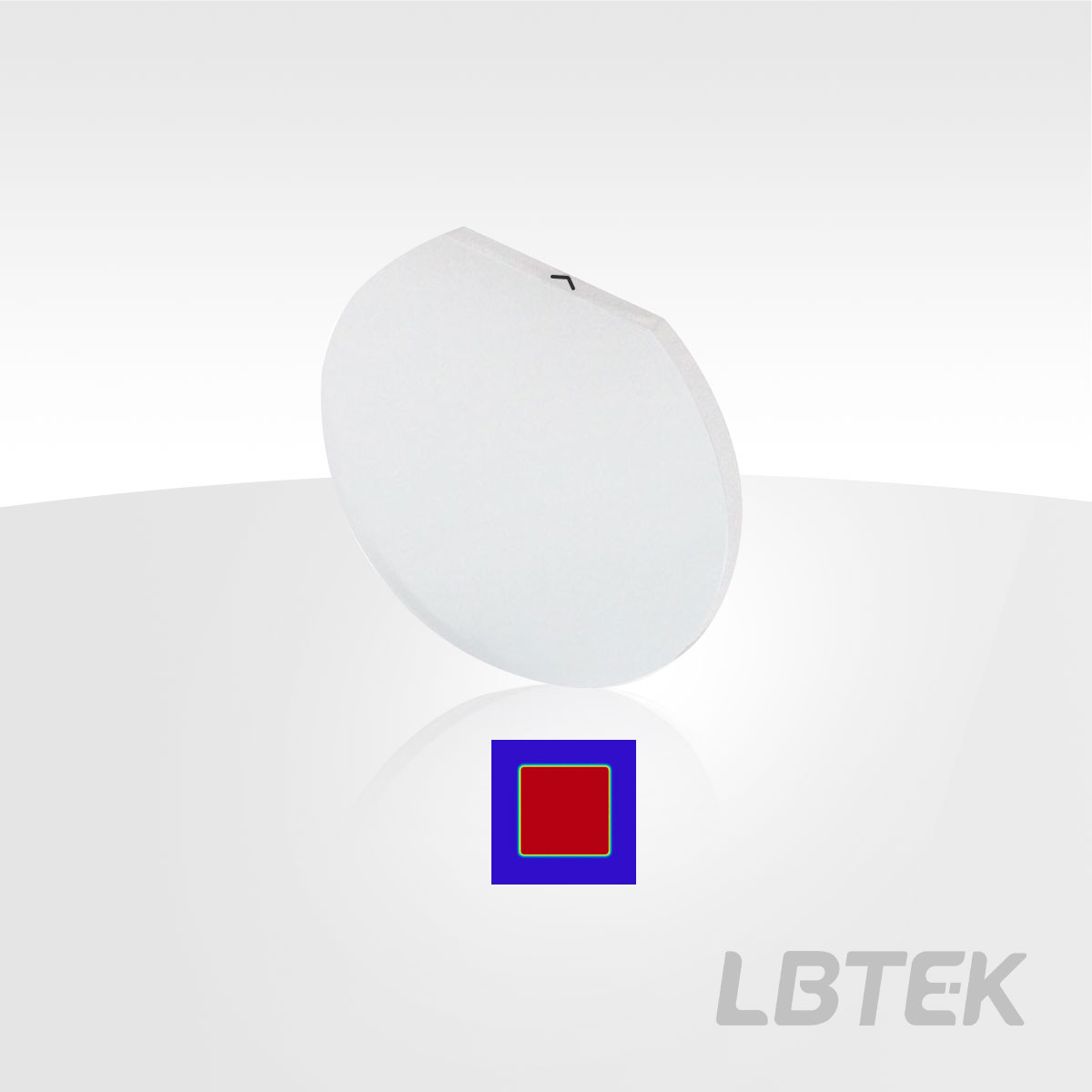

- Material: Liquid Crystal Polymer/N-BK7 Window

- Focal Length: 5 mm, 50 mm

- Clear Aperture: Ø21.5 mm

- The Product's Cutting Edge Direction is Parallel to One Side of the Emitted Square Beam

The LBTEK flat microlens array is fabricated on an N-BK7 window substrate with a single-layer structure. One side of the window is coated with a liquid crystal polymer film that provides uniform phase retardation across the entire clear aperture, equivalent to half of the working wavelength. The other side is coated with an anti-reflection (AR) coating, and it is recommended that light enters from the AR-coated side. The output beam profile depends on the parameters of the microlens units, with the standard product producing a square-shaped output beam aligned parallel to one edge of the square. LBTEK offers various customization services. For specific customization requirements, please contact technical support.

Friendly Reminders:

● This product features a single-layer protective substrate. Please distinguish between the AR-coated surface (incident surface) and the liquid crystal polymer surface. The side indicated by the tip of the "V" marking is the liquid crystal polymer surface.

● Avoid any form of physical contact, such as scratching or rubbing, with the liquid crystal polymer surface.

● Do not clean the liquid crystal polymer surface with alcohol, water, acetone, or similar solvents. For cleaning, prioritize non-contact methods such as using an air gun.

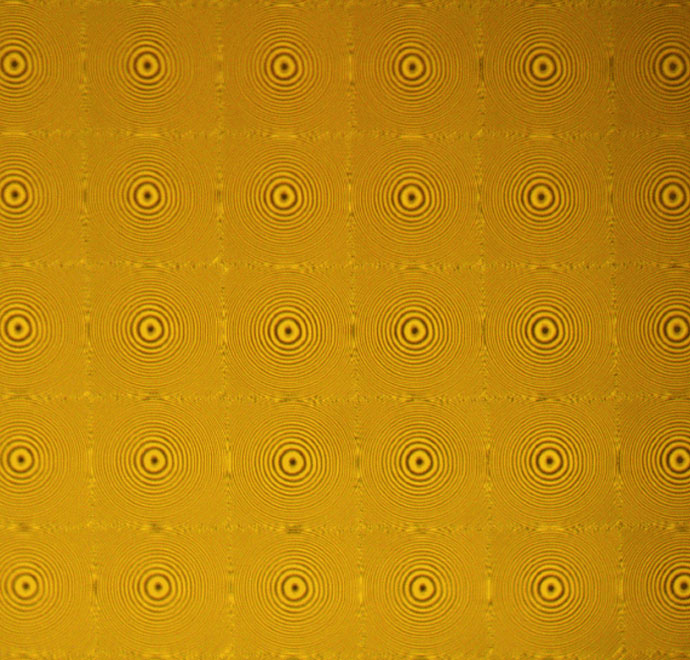

Structure diagram of flat microlens array under polarized light microscope

Product Model | Operating Wavelength | Focal length | Microlens unit size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| PBMLA25S-532-F50 | 532 nm | 50 mm | 300 μm×300 μm | $1,280.22 | 3 weeks | Add Cart | ||

| PBMLA25S-633-F50 | 633 nm | 50 mm | 300 μm×300 μm | $1,280.22 | 3 weeks | Add Cart | ||

| PBMLA25S-850-F50 | 850 nm | 50 mm | 300 μm×300 μm | $1,280.22 | 3 weeks | Add Cart |