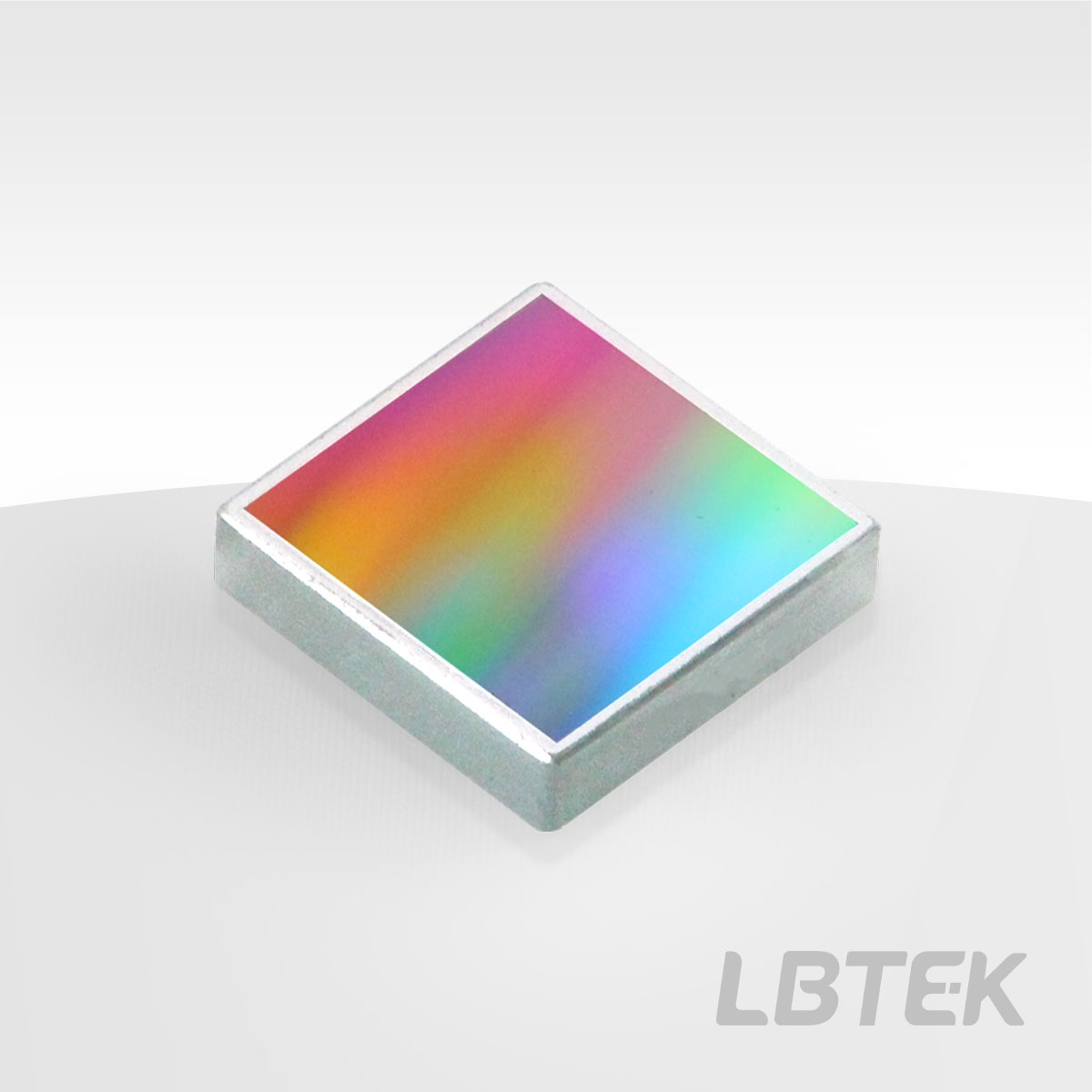

- Optical element material: soda-lime glass

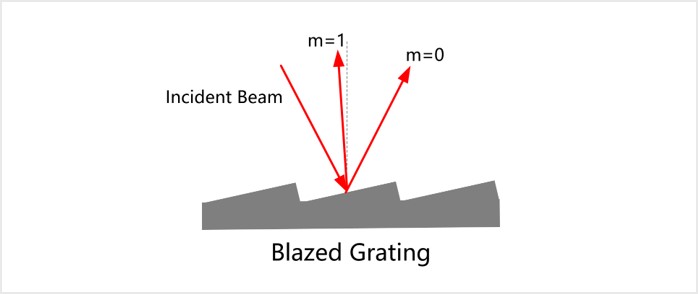

- Blaze wavelength options: 300 nm, 500 nm, 750 nm, 1000 nm, 1250 nm, 1500 nm

- Diffraction efficiency at blaze wavelength: 60%~80%

- Grating surface coated with aluminum film (without protective layer)

- Blaze Wavelength: 300 nm, 500 nm, 750 nm, 1000 nm, 1250 nm, 1500 nm

- Diffraction Efficiency Corresponding to Blaze Wavelength as high as 60% to 80%

- Capable to Grate Surface Aluminum Coating (Unprotected)

Product Model | Blaze Wavelength | Grating Period | Blaze Angle | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| BG25-600-1500 | 1500 nm | 600 lines/mm | 26.78° | $102.24 | today | Add Cart | ||

| BG25-1200-1000 | 1000 nm | 1200 lines/mm | 36.86° | $102.24 | today | Add Cart | ||

| BG25-600-1250 | 1250 nm | 600 lines/mm | 22.02° | $102.24 | today | Add Cart | ||

| BG25-600-1000 | 1000 nm | 600 lines/mm | 17.46° | $100.28 | today | Add Cart | ||

| BG25-300-1000 | 1000 nm | 300 lines/mm | 8.63° | $100.28 | today | Add Cart | ||

| BG25-1200-750 | 750 nm | 1200 lines/mm | 26.74° | $103.29 | today | Add Cart | ||

| BG25-600-750 | 750 nm | 600 lines/mm | 13.00° | $103.29 | today | Add Cart | ||

| BG25-1200-500 | 500 nm | 1200 lines/mm | 17.46° | $103.29 | today | Add Cart | ||

| BG25-600-500 | 500 nm | 600 lines/mm | 8.63° | $103.29 | today | Add Cart | ||

| BG25-300-300 | 300 nm | 300 lines/mm | 2.58° | $103.29 | today | Add Cart | ||

| BG13-600-500 New | 500 nm | 600 lines/mm | 8.63° | $84.98 | today | Add Cart |

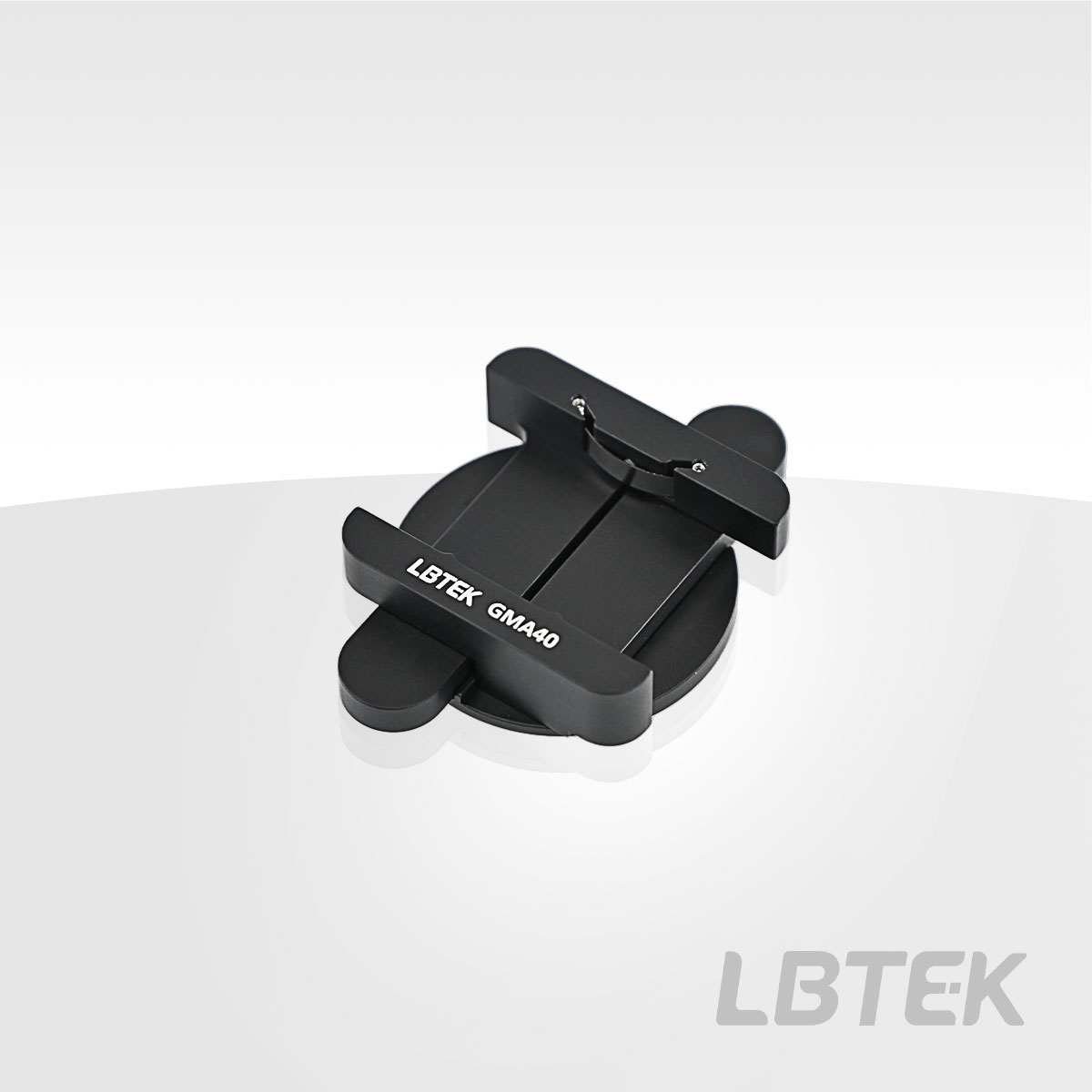

- Material: 6061-T6 Aluminum Alloy

- Clamping Height Range: 20-40 mm

- Minimum Clamping Width: 18 mm

- Clamping Thickness: 5-10 mm

The grating adjustment mount adapter from LBTEK can be installed on Ø1-inch smooth-bore optical adjustment mounts. This assembly approach facilitates the adjustment of the pitch and yaw angles of the clamped grating. Morever, the adapter is characterized by a simple structure. By sliding the clamping blocks located above and below the adapter, the connecting screws on the rear side of the blocks can move along the machined slots, enabling height adjustment for the clamped grating and rectangular lenses. Tightening the two M3 connecting screws on the rear side secures the positions of the grating and rectangular lenses. This adapter adopts a three - point fixation mechanism, and its adjustable mounting system comprises two bottom contact lines and a top contact that utilizes a planar spring.

The grating adjustment mount adapter is mounted on a 1-inch lens mount.

Product Model | Maximum clampable height | Minimum clamping width | Maximum clampable thickness | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| GMA40 | 20-40 mm | 18 mm | 5-10 mm | $134.01 | today | Add Cart |