Specifications

Curve

Tutorial

Assembly

Application

Customization

Calculator

Feedback

Product Description

- Liquid crystal polymer/N-BK7 window plate or UVFS window plate material, Sandwich flat plate structure

- The fast-axis orientation of liquid crystal molecules exhibiting different periodic variations depending on the design, with λ/2 retardation

- Capable to generate square flat-top beams, circular flat-top beams, or line-shaped flat-top beams

- High diffraction efficiency, High uniformity, High damage threshold, Sharp edges, Customizable shape and size

- Operating wavelength: 532, 1064 nm; Output beam shapes: square, circular, line-shaped

- Flexible customization of parameters and specifications available

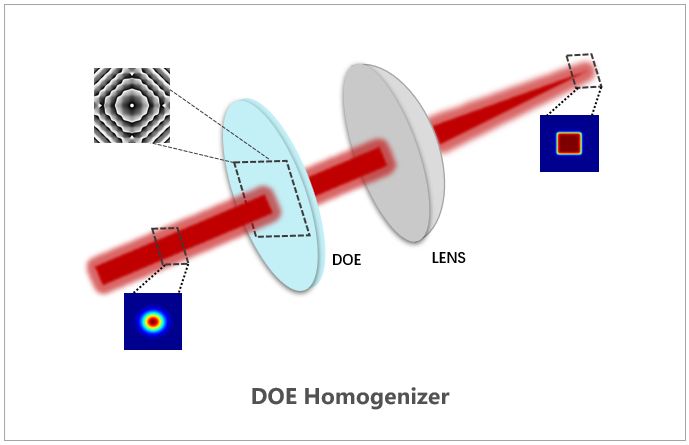

The LBTEK Polymer Homogenizing DOE is a flat optical element designed based on the principles of diffractive optics, composed of a liquid crystal polymer (LCP) film and two N-BK7 or UVFS window substrates. By calculating the design phase through point-to-point mapping based on known incident light parameters, lens focal length, and desired output light parameters, the LCP film introduces the designed geometric phase distribution to shape and homogenize Gaussian (TEM00, M²<1.3) incident light. With advantages such as high uniformity, high transmittance, high damage threshold, and sharp edges, it holds significant application potential in various fields, including laser medical aesthetics, laser processing, and surface treatment. Compared to traditional refractive homogenizing devices, the Polymer Homogenizing DOE offers benefits such as a flat structure for easy integration, high energy efficiency, and flexible parameter design. In contrast to array lens phase homogenizers, the Polymer Homogenizing DOE achieves excellent homogenization with a single element, producing output spots with sharper edges, though it requires more precise incident light parameters.

The Polymer Homogenizing DOE is often used in conjunction with focusing lenses for more flexible beam shaping and homogenization. Therefore, our standard products are all focusing beam shapers, designed to work with standard lenses (default f=100 mm). Available options include working wavelengths of 532 nm and 1064 nm, output spot shapes of square, circular, or line types, and substrate materials of N-BK7 glass or UV-grade fused silica. In addition to standard products, LBTEK also offers flexible customization of parameters. For specific customization needs, please contact LBTEK Technical Support.

Diagram

Attributes

Incident beam qualityM2<1.3

Incident light eccentricity (XY displacement)±5% (× incident spot diameter)

Incident light spot polarization stateUniform polarization state

Incident light tilt±5 °

Unevenness (RMS)<10 %

Diffraction efficiency (FWHM)>90 %

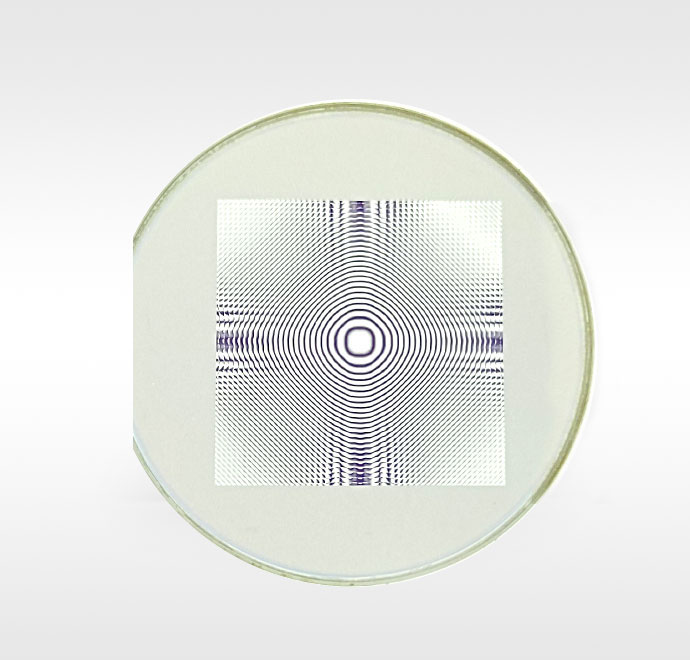

Polymer Homogenization DOEs, N-BK7 Substrate, Square Type

- LCP\/N-BK7 Window Plate

- Clear Aperture: 15×15 mm

- Converts TEM00 Gaussian Beam into Square Uniform Spot

LBTEK Polymer Homogenizer DOE is fabricated on a 1.6 mm thick N-BK7 window substrate, featuring a double-layer substrate with a single-layer liquid crystal polymer film. It provides uniform λ/2 retardation across the entire clear aperture, capable of transforming incident TEM00 Gaussian beams into square-shaped uniform spots. The product comes without a mechanical housing and has a D-shaped edge on one side, which is parallel to one edge of the output square spot for convenient customer installation and use.

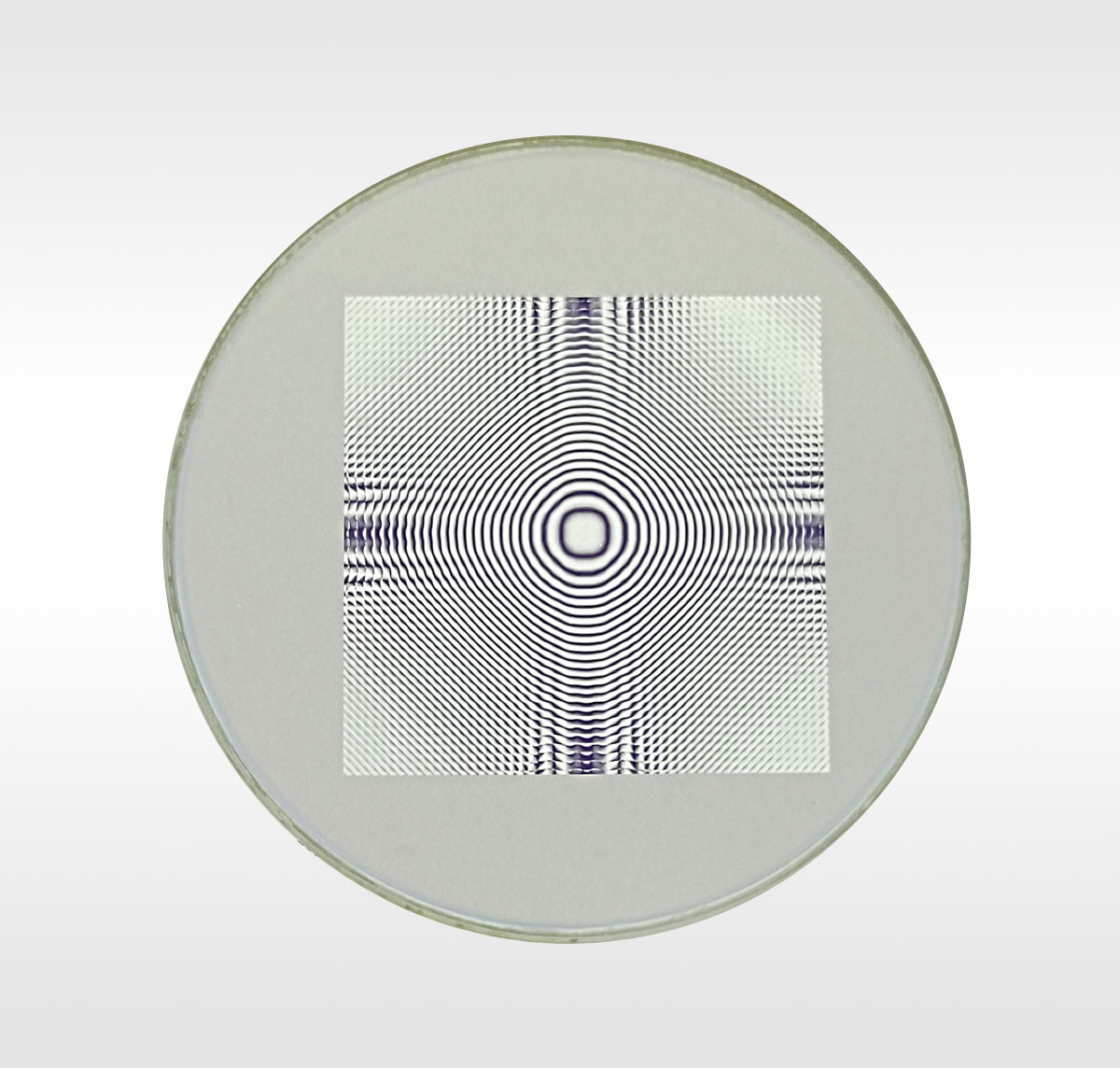

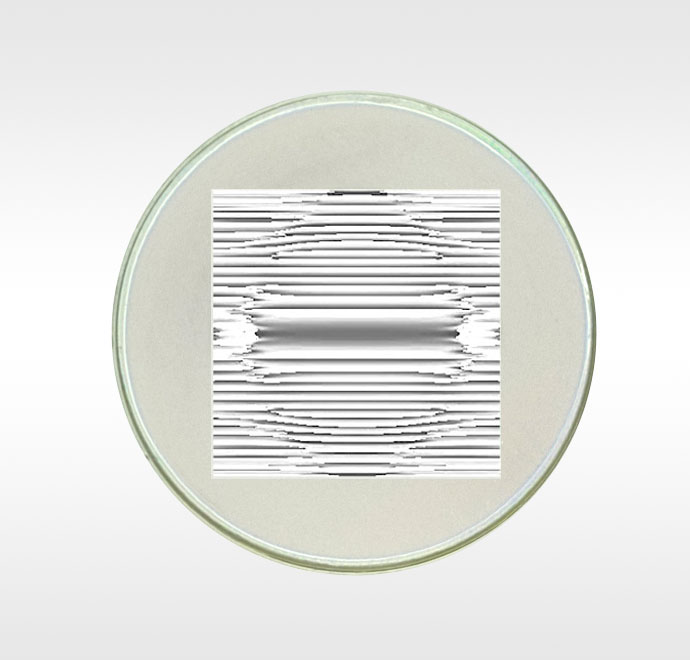

DOE25-532-6-FTS200 under linear polarizer

Product Model | Operating Wavelength | Incident spot diameter | Effective Focal Length (EFL) | Output beam spot size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| DOE25-532-6-FTS50 | 532 nm | 6 mm | 100 mm | 50×50 μm | $1,300.22 | 4 weeks | Add Cart | ||

| DOE25-532-7-FTS30 | 532 nm | 7 mm | 100 mm | 30.3×30.3 μm | $1,300.22 | 4 weeks | Add Cart | ||

| DOE25-532-7-FTS76 | 532 nm | 7 mm | 100 mm | 75.8×75.8 μm | $1,300.22 | 4 weeks | Add Cart | ||

| DOE25-1064-6-FTS80 | 1064 nm | 6 mm | 100 mm | 80×80 μm | $1,300.22 | 4 weeks | Add Cart | ||

| DOE25-1064-6-FTS200 | 1064 nm | 6 mm | 100 mm | 200×200 μm | $1,300.22 | 4 weeks | Add Cart | ||

| DOE25-1064-7-FTS30 | 1064 nm | 7 mm | 100 mm | 30.3×30.3 μm | $1,300.22 | 4 weeks | Add Cart | ||

| DOE25-1064-7-FTS76 | 1064 nm | 7 mm | 100 mm | 75.8×75.8 μm | $1,300.22 | 4 weeks | Add Cart |

Polymer Homogenization DOEs, N-BK7 Substrate, Circular Type

- Liquid Crystal Polymer/N-BK7 Window Plate

- Clear Aperture: Ø15 mm

- Converts TEM00 Gaussian Beam into Circular Uniform Spot

LBTEK polymer homogenizing DOE is fabricated on a 1.6 mm thick N-BK7 window substrate, featuring a double-layer substrate with a single-layer liquid crystal polymer film. It provides uniform λ/2 retardation across the entire clear aperture, capable of transforming incident TEM00 Gaussian beams into circular uniform spots. The product comes without a mechanical housing and has a D-shaped edge on one side for convenient customer installation and use.

DOE25-532-6-FTC200 under linear polarizer

Product Model | Operating Wavelength | Incident spot diameter | Effective Focal Length (EFL) | Output beam spot size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| DOE25-532-6-FTC50 | 532 nm | 6 mm | 100 mm | Ø50 μm | $1,300.22 | 4 weeks | Add Cart | ||

| DOE25-1064-6-FTC80 | 1064 nm | 6 mm | 100 mm | Ø80 μm | $1,300.22 | 4 weeks | Add Cart | ||

| DOE25-1064-6-FTC200 | 1064 nm | 6 mm | 100 mm | Ø200 μm | $1,300.22 | 4 weeks | Add Cart |

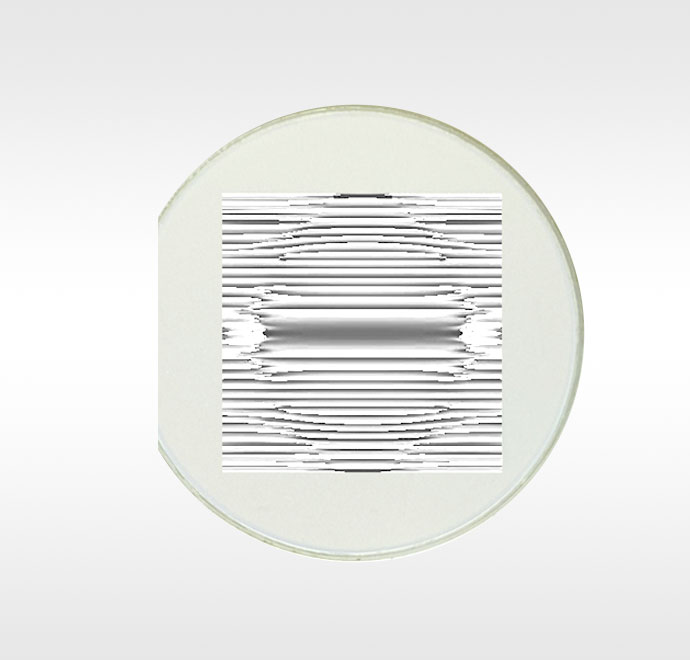

Polymer Homogenization DOEs, N-BK7 Substrate, Single-line Type

- Liquid Crystal Polymer/N-BK7 Window Plate

- Clear Aperture: 15×15 mm

- Converts TEM00 Gaussian Beam into a Uniform Line-shaped Spot

LBTEK Polymer Homogenizer DOE is fabricated on a 1.6 mm thick N-BK7 window substrate, featuring a double-layer substrate with a single-layer liquid crystal polymer film. It provides uniform λ/2 retardation across the entire clear aperture, capable of transforming incident TEM00 Gaussian beams into a uniform one-dimensional line-shaped spot. The line length is designed as specified, while the line width reaches the diffraction limit. The product comes without a mechanical housing and has a D-shaped edge on one side, which is parallel to the emitted line-shaped spot for convenient customer installation and use.

DOE25-532-6-FTL250 under linear polarizer

Product Model | Operating Wavelength | Incident spot diameter | Effective Focal Length (EFL) | Output beam spot size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| DOE25-532-6-FTL250 | 532 nm | 6 mm | 100 mm | 250 μm | $1,040.18 | 4 weeks | Add Cart | ||

| DOE25-532-6-FTL1000 | 532 nm | 6 mm | 100 mm | 1000 μm | $1,040.18 | 4 weeks | Add Cart | ||

| DOE25-1064-6-FTL250 | 1064 nm | 6 mm | 100 mm | 250 μm | $1,040.18 | 4 weeks | Add Cart | ||

| DOE25-1064-6-FTL1000 | 1064 nm | 6 mm | 100 mm | 1000 μm | $1,040.18 | 4 weeks | Add Cart |

Polymer Homogenization DOEs, UVFS Substrate, Square Type

- Liquid Crystal Polymer\/Fused Silica Window Plate

- Clear Aperture: 15×15 mm

- Converts TEM00 Gaussian Beam Into Square Uniform Spot

The LBTEK polymer homogenizing DOE is fabricated on a 3 mm thick fused silica window substrate, featuring a double-layer substrate with a single-layer liquid crystal polymer film. It provides uniform λ/2 retardation across the entire clear aperture, capable of shaping and homogenizing incident TEM00 Gaussian beams into square-shaped uniform spots. Compared to DOE homogenizers with N-BK7 substrates, the fused silica-based DOE homogenizer is more suitable for high-power laser applications.

DOE25H-532-6-FTS200 under linear polarizer

Product Model | Operating Wavelength | Incident spot diameter | Effective Focal Length (EFL) | Output beam spot size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| DOE25H-532-6-FTS50 | 532 nm | 6 mm | 100 mm | 50×50 μm | $1,560.26 | 4 weeks | Add Cart | ||

| DOE25H-532-7-FTS30 | 532 nm | 7 mm | 100 mm | 30.3×30.3 μm | $1,560.26 | today | Add Cart | ||

| DOE25H-532-7-FTS76 | 532 nm | 7 mm | 100 mm | 75.8×75.8 μm | $1,560.26 | 4 weeks | Add Cart | ||

| DOE25H-1064-6-FTS80 | 1064 nm | 6 mm | 100 mm | 80×80 μm | $1,560.26 | 4 weeks | Add Cart | ||

| DOE25H-1064-6-FTS200 | 1064 nm | 6 mm | 100 mm | 200×200 μm | $1,560.26 | 4 weeks | Add Cart | ||

| DOE25H-1064-7-FTS30 | 1064 nm | 7 mm | 100 mm | 30.3×30.3 μm | $1,560.26 | 4 weeks | Add Cart | ||

| DOE25H-1064-7-FTS76 | 1064 nm | 7 mm | 100 mm | 75.8×75.8 μm | $1,560.26 | 4 weeks | Add Cart |

Polymer Homogenization DOEs, UVFS Substrate, Circular Shape

- Liquid Crystal Polymer\/Fused Silica Window

- Clear Aperture: Ø15 mm

- Converts TEM00 Gaussian Beam into Circular Uniform Spot

The LBTEK polymer homogenizing DOE is fabricated on a 3 mm thick N-BK7 window substrate, consisting of a double-layer substrate with a single-layer liquid crystal polymer film. It provides uniform λ/2 retardation across the entire clear aperture, capable of transforming incident TEM00 Gaussian beams into circular, homogenized spots. Compared to N-BK7 substrate-based DOE homogenizers, fused silica substrate-based DOE homogenizers are more suitable for high-power laser applications.

DOE25H-532-6-FTC200 under linear polarizer

Product Model | Operating Wavelength | Incident spot diameter | Effective Focal Length (EFL) | Output beam spot size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| DOE25H-532-6-FTC50 | 532 nm | 6 mm | 100 mm | Ø50 μm | $1,560.26 | 4 weeks | Add Cart | ||

| DOE25H-1064-6-FTC80 | 1064 nm | 6 mm | 100 mm | Ø80 μm | $1,560.26 | 4 weeks | Add Cart | ||

| DOE25H-1064-6-FTC200 | 1064 nm | 6 mm | 100 mm | Ø200 μm | $1,560.26 | 4 weeks | Add Cart |

Polymer Homogenization DOEs, UVFS Substrate, Single-line Pattern

- Liquid Crystal Polymer\/Fused Silica Window Plate

- Clear Aperture: 15×15 mm

- Converts TEM00 Gaussian Beam into a Uniform Line-shaped Spot

The LBTEK polymer homogenizing DOE is fabricated on a 3 mm thick N-BK7 window substrate, consisting of a double-layer substrate with a single-layer liquid crystal polymer film. It provides uniform λ/2 retardation across the entire clear aperture, capable of transforming incident TEM00 Gaussian beams into a uniform line-shaped spot. The line length matches the design specification, while the line width reaches the diffraction limit. Compared to DOE homogenizers with N-BK7 substrates, those with fused silica substrates are more suitable for high-power laser applications.

DOE25H-532-6-FTL250 under linear polarizer

Product Model | Operating Wavelength | Incident spot diameter | Effective Focal Length (EFL) | Output beam spot size | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|---|

| DOE25H-532-6-FTL250 | 532 nm | 6 mm | 100 mm | 250 μm | $1,248.19 | 4 weeks | Add Cart | ||

| DOE25H-532-6-FTL1000 | 532 nm | 6 mm | 100 mm | 1000 μm | $1,248.19 | 4 weeks | Add Cart | ||

| DOE25H-1064-6-FTL250 | 1064 nm | 6 mm | 100 mm | 250 μm | $1,248.19 | 4 weeks | Add Cart | ||

| DOE25H-1064-6-FTL1000 | 1064 nm | 6 mm | 100 mm | 1000 μm | $1,248.19 | 4 weeks | Add Cart |