Specifications

Curve

Tutorial

Assembly

Application

Customization

Feedback

Product Description

- Linearly polarized light incidence, one-dimensional odd or even uniform beam splitting available

- Planar structure, high splitting ratio, high diffraction efficiency

- Working wavelength: 532 nm, 1064 nm, splitting angle: 2°, 4°, splitting mode: 1×7

- Liquid crystal polymer/N-BK7 window plate, sandwich flat plate structure, no housing, with a single cutting edge

- The fast axis orientation of liquid crystal molecules shows 0-90° binary periodic variation along the x-axis, λ/2 retardation

- Custom sizes available for parameter specifications

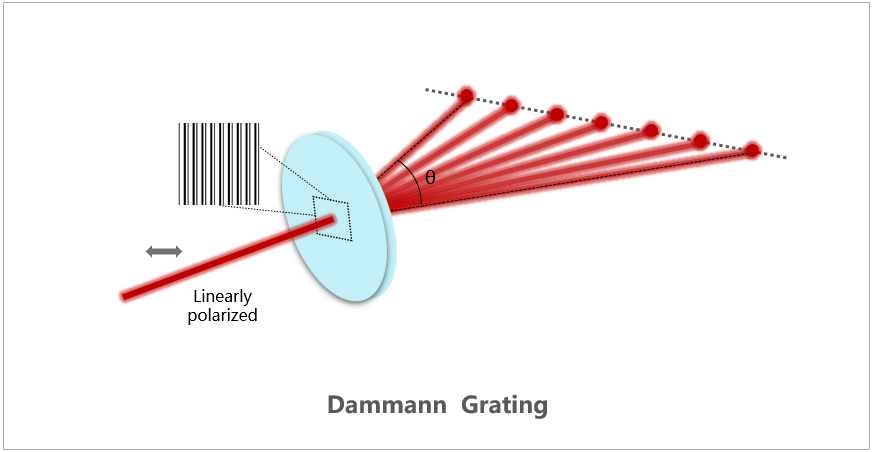

LBTEK Dammann Grating (DG) is fabricated based on liquid crystal polymer birefringent material and N-BK7 glass substrate, presenting a sandwich structure of "front and rear glass substrates + LCP functional layer" with no housing and a single cutting edge. In the LCP layer, the fast-axis orientation of liquid crystal molecules exhibits a binary periodic variation of 0-90° along the x-axis, with a λ/2 retardation across the entire device plane, making it a single-wavelength device. The surface of the Dammann grating consists of a series of position-encoded binary phase structures, capable of splitting a laser beam into multiple beams with equal intensity. It features unique advantages such as a flat-plate structure, high diffraction efficiency, and high beam-splitting ratio. Compared to gratings and cascaded grating beam splitters, the Dammann grating can achieve odd-number beam splitting and higher-point beam splitting with a single element. LBTEK offers standard Dammann gratings

Diagram

Attributes

Component MaterialLiquid Crystal Polymer/N-BK7 Window Plate

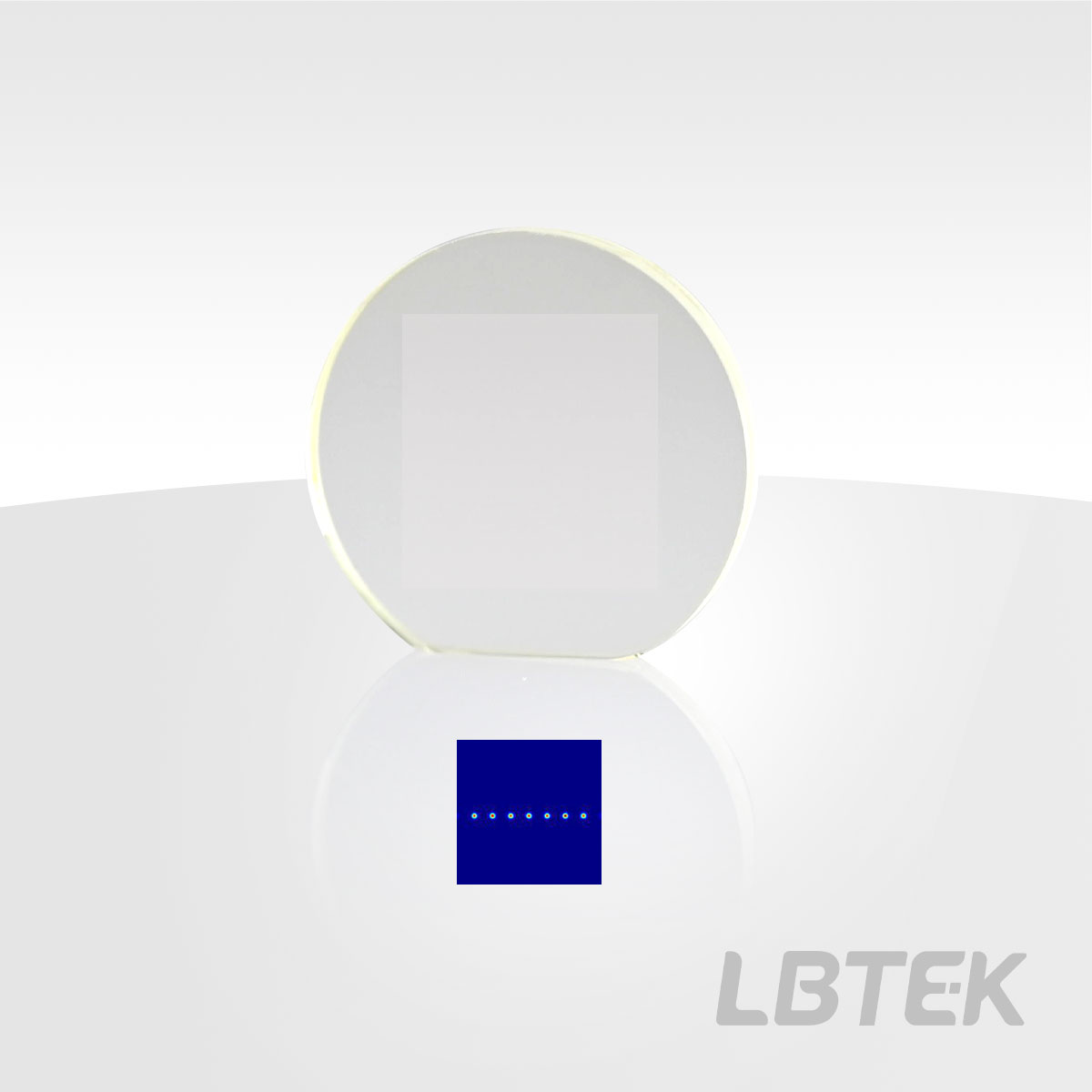

Component sizeØ25.4×3.2 mm, D-type 1.5 mm cutting edge

Delay accuracy±5 nm

Surface finish (scratches/pits)60/40

Delay Uniformity±5 nm

Operating Temperature-20~80 ℃

Beam splitting uniformity>85%

One-dimensional Dammann Gratings

- Linear Polarized Light Incidence, capable to achieve one-dimensional 1×7 uniform beam splitting

- Odd-number BeamSplitter, High Diffraction Efficiency, High Splitting Ratio

- Standard Wavelengths 532, 1064 nm Optional

The LBTEK 1×7 Dammann grating has a phase difference of π between adjacent strip regions, achieving a uniform 1×7 beam splitting effect. When the incident light is linearly polarized, the splitting uniformity is optimal, and the diffraction efficiency can reach the theoretical value. The standard product does not come with a mechanical housing and features a single-sided 1.5 mm cut edge, with the cutting direction parallel to the grating lines. The standard 1×7 Dammann grating has a period of 90 μm. To ensure uniform beam splitting spots, it is recommended that the incident beam diameter be greater than 0.3 mm.

1×7 Dammann Grating Polarized Microscope Structure

Product Model | Operating Wavelength | Beam splitting mode | Maximum Beam Splitting Angle (Full Angle) | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| DG25-1702-532 | 532 nm | 1×7 | 2 ° | $1,040.18 | 5 weeks | Add Cart | ||

| DG25-1704-1064 | 1064 nm | 1×7 | 4 ° | $1,040.18 | 5 weeks | Add Cart |