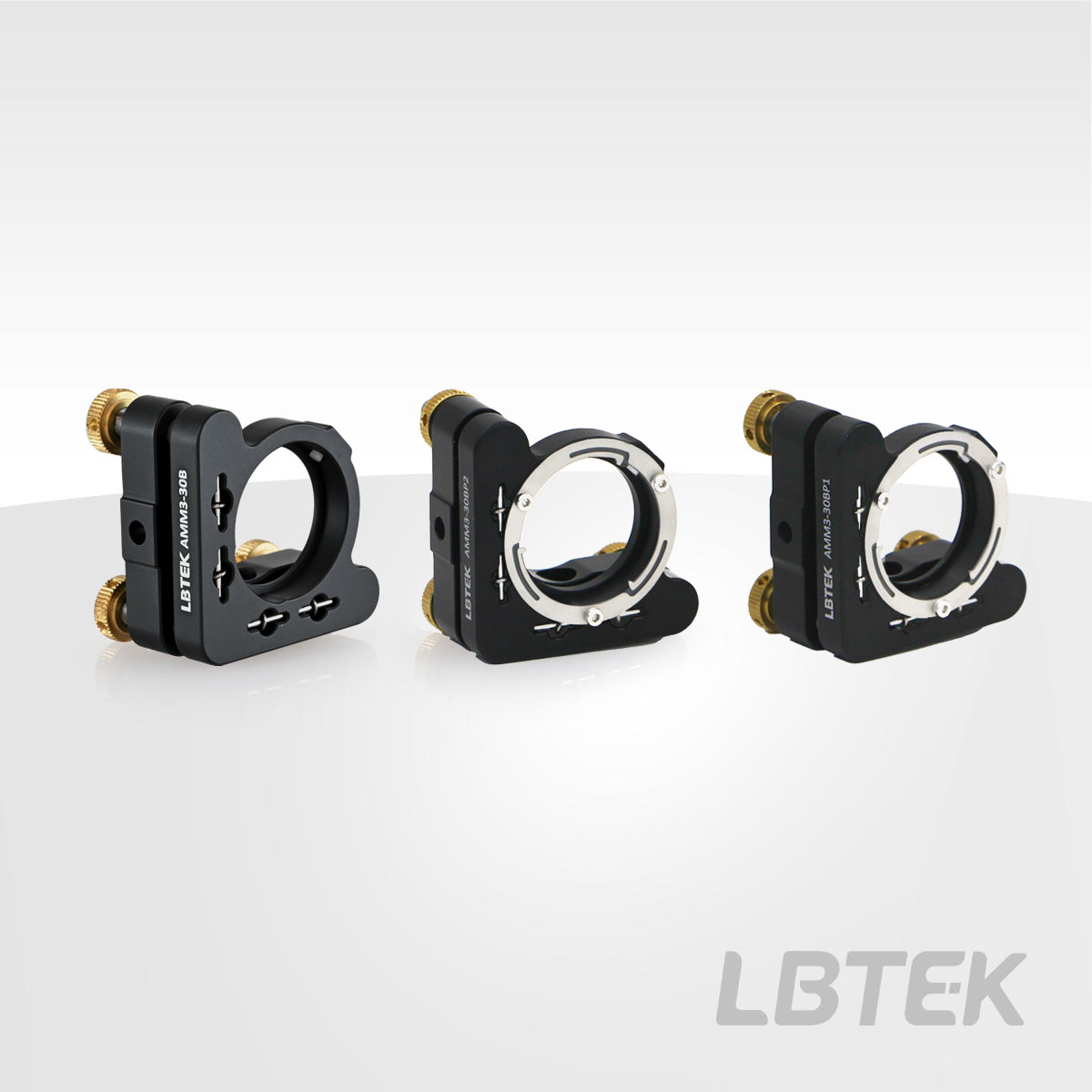

- Cost-effective industrial-grade mirror mounts

- 4 tension spring design for enhanced structural stability

- Adjusters with locknuts ensure long-term stability

- Applicable to optical component diameter: 30.0 mm

- Minimum thickness of applicable optical components: 3.0 mm

- Adjustable angle range ±4°, 0.4° per rotation

- Adjuster with locknut for locking

- Optical component secured by set screws or a dual clamping with set screws plus a elastic retaining ring

The LBTEK Standard 3-Axis O-Type Optical Mount is for optical components with a diameter of Ø30.0 mm and an optical axis height of 25.4 mm. The base of the mount features counterbore holes for M4 screws to connect mounting rods. The AMM3-30B model uses set screws to secure optical components, suitable for components with a diameter of 30.0 mm and a minimum thickness of 3.0 mm. The AMM3-30BP1 and AMM3-30BP2 models employ a dual clamping mechanism combining set screws with elastic retaining rings. The set screws can secure components with a minimum thickness of 3 mm, while the dual clamping rings accommodate thicknesses of 6.5 mm and 5.0 mm respectively. The mount is equipped with three M6×0.25 precision adjusters that can be locked with locknuts, providing pitch and yaw adjustment ranges of ±4° with 0.4° per revolution. The adjusters do not include knobs and can be operated using a 2.0 mm hex wrench or a knurled hex wrench (HWS-2). Purchasing LBTEK Standard 3-Axis O-Type Optical Mount includes one 2.0 mm hex wrench and two M4 socket head cap screws as complimentary accessories.

Ø12.7 mm Post Supporting the Mount

Product Model | Applicable optical element diameter | Optical component mounting method | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| AMM3-30BP2 | Ø30.0 mm | Set screw with elastic retaining ring for dual clamping | $50.34 | 4 weeks | Add Cart | ||

| AMM3-30BP1 | Ø30.0 mm | Set screw with elastic retaining ring for dual clamping | $50.34 | 4 weeks | Add Cart | ||

| AMM3-30B | Ø30.0 mm | M4 rubber-tipped set screw | $46.94 | today | Add Cart |

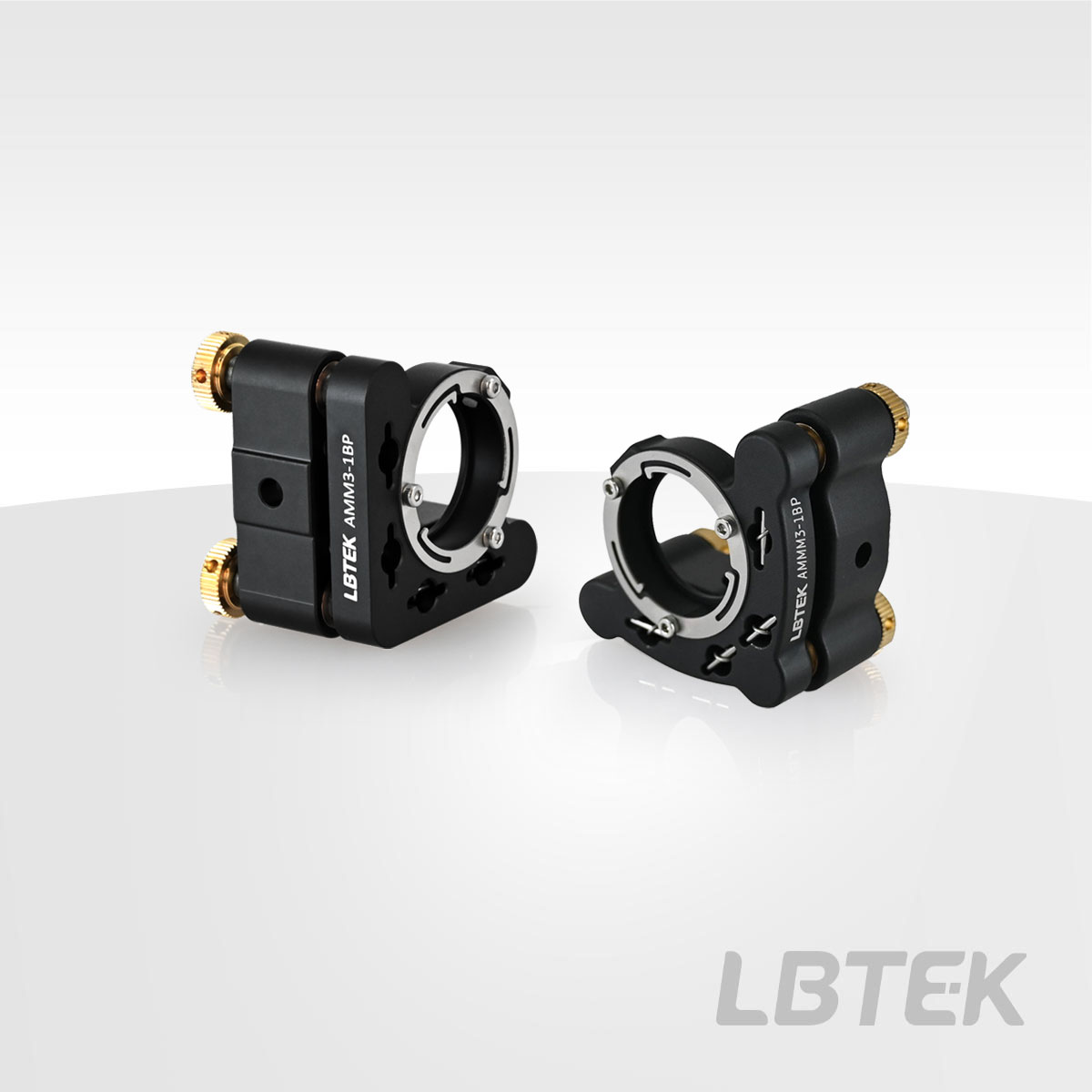

- Applicable to optical component diameter: 25.4 mm

- Minimum thickness of optical component: 3.0 mm

- Adjustable angle range ±4°, 0.41° per rotation

- Adjuster with locknuts for locking

- Optical component secured with set screws

The LBTEK Standard O-Type Optical Mount AMM3-1BP uses both set screws and an elastic retaining ring for dual clamping and securing of optical components, with an optical axis height of 25.4 mm. The base of the mount features counterbore holes for M4 screws, used for connecting mounting rods. The mount can accommodate optical components with a diameter of 25.4 mm and a minimum thickness of 3.0 mm. It is equipped with three M6×0.25 precision adjusters that can be locked with locknuts, providing adjustment ranges of ±4° in pitch and yaw, with 0.41° per rotation. The adjusters do not come with knobs but can be adjusted using the included knurled hex wrench HWS-2. Purchasing the LBTEK Standard O-Type Optical Mount includes one knurled hex wrench HWS-2 and two M4 socket head cap screws. The AMMM3-1BP has a short processing cycle, meeting the mass production and rapid delivery requirements. It employs two tension springs with wire diameters of 0.65 mm and two with 0.8 mm, ensuring better stability for the optical mount.

Ø12.7 mm Post Supporting the Mount

Product Model | Applicable optical element diameter | Minimum applicable thickness for optical components | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| AMM3-1BP | Ø25.4 mm | 3.0 mm | $47.20 | today | Add Cart | ||

| AMMM3-1BP | Ø25.4 mm | 3.0 mm | $45.37 | today | Add Cart |

- Applicable to optical component diameter: 25.4 mm

- Minimum thickness of applicable optical component: 3.0 mm

- Adjustable angle range ±4°, 0.4° per rotation

- Adjuster with locknuts for locking

- Optical component secured by set screws or a dual clamping with set screws plus a elastic retaining ring

The LBTEK Standard 2-Axis O-Type Optical Mount is for optical components with a diameter of Ø25.4 mm and an optical axis height of 25.4 mm. The base of the mount features counterbore holes for M4 screws for connection and installation. The AMM-1BL model uses set screws to secure optical components and can accommodate a minimum thickness of 3 mm. The AMM-1BP model employs a dual clamping mechanism with set screws and an elastic retaining ring to fix optical components. The set screws can secure components with a minimum thickness of 3 mm, while the dual clamping ring can hold components up to 6.5 mm thick. The mount is equipped with two M6×0.25 precision adjusters, which can be locked with locknuts, providing pitch and yaw adjustment ranges of ±4° with 0.4° per rotation. The adjusters do not come with knobs but can be adjusted using a 2.0 mm hex wrench or an HWS-2 hex wrench with a knob. Purchasing the LBTEK Standard O-Type Optical Mount includes one 2.0 mm hex wrench and two M4 cylindrical head hex screws. The AMMM-1BL and AMMM-1BP models have short processing cycles, meeting the mass production and rapid delivery requirements. They use two tension springs with wire diameters of 0.65 mm and 0.8 mm, respectively, ensuring better stability for the optical mount.

Ø12.7 mm Post Supporting AMM-1BP

Product Model | Applicable optical element diameter | Optical component mounting method | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|

| AMM-1BP | Ø25.4 mm | Set screw with elastic retaining ring for dual clamping | $46.41 | today | Add Cart | ||

| AMM-1BL | Ø25.4 mm | M4 rubber-tipped set screw | $45.89 | today | Add Cart | ||

| AMMM-1BL | Ø25.4 mm | M4 rubber-tipped set screw | $44.06 | today | Add Cart | ||

| AMMM-1BP | Ø25.4 mm | Set screw with elastic retaining ring for dual clamping | $44.58 | today | Add Cart |