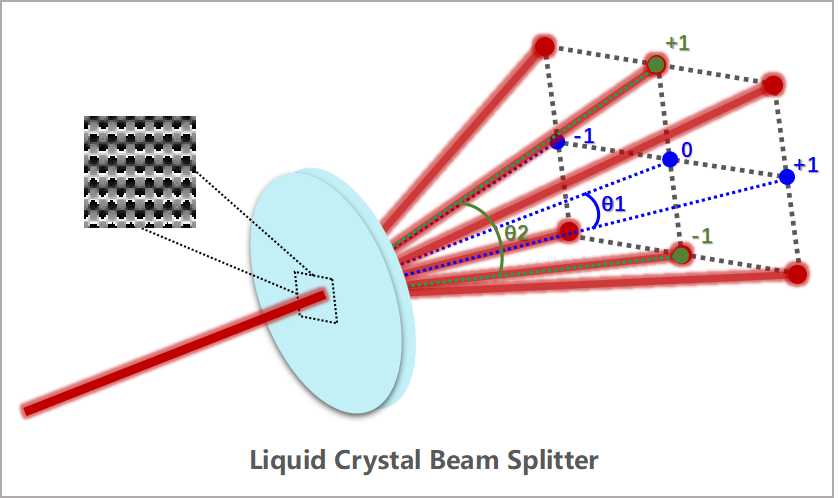

- Liquid crystal polymer/N-BK7 window or UVFS window, sandwich flat structure

- Liquid crystal molecular fast axis with different periodic arrangements depending on beam splitting design, λ/2 retardation

- One-dimensional or two-dimensional, odd or even uniform beam splitting available

- High diffraction efficiency, high beam splitting uniformity, high separation angle accuracy, low invalid diffraction order noise impact

- Operating wavelength: 532 nm, 1064 nm, beam splitting modes: 1×3, 1×9, 2×3

- Custom sizes with parameter specifications available

- Liquid Crystal Polymer/N-BK7 Window

- Clear Aperture: Ø21.5 mm

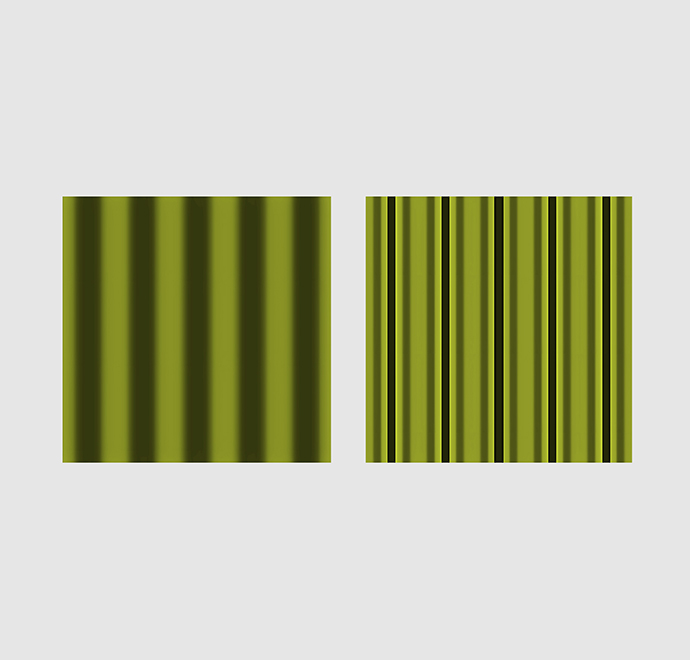

- 1×3 and 1×9 Uniform Beam Splitting Effects Available

The LBTEK one-dimensional polymer beamsplitter DOE is fabricated on a 1.6 mm thick N-BK7 window substrate, featuring a double-layer substrate with a single-layer liquid crystal polymer film structure. It maintains a uniform λ/2 retardation across the entire clear aperture. Standard products can achieve 1×3 and 1×9 one-dimensional beam-splitting effects. The product is supplied as a bare die without mechanical housing and can be used with 1-inch rotation mounts to adjust the geometric orientation of the split beams.

Product Model | Operating Wavelength | Beam splitting mode | Separation angle | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| LCBS25-532-0103-000050 | 532 nm | 1×3 | 0.5 ° | $1,040.18 | 4 weeks | Add Cart | ||

| LCBS25-532-0109-000015 | 532 nm | 1×9 | 0.15 ° | $1,040.18 | 5 weeks | Add Cart | ||

| LCBS25-1064-0103-000100 | 1064 nm | 1×3 | 1 ° | $1,040.18 | 4 weeks | Add Cart | ||

| LCBS25-1064-0109-000030 | 1064 nm | 1×9 | 0.3 ° | $1,040.18 | 5 weeks | Add Cart |

- Liquid Crystal Polymer/N-BK7 Window Plates

- Clear Aperture: Ø21.5 mm

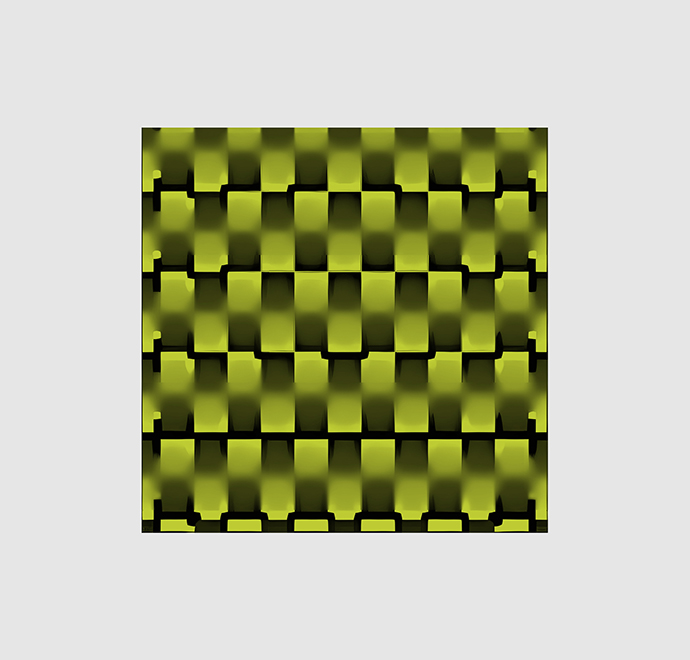

- 2×3 uniform Beam Splitting Effect Available

LBTEK 2D polymer beamsplitter DOE is fabricated on a 1.6 mm thick N-BK7 window substrate, featuring a double-layer substrate with a single-layer liquid crystal polymer film structure. It maintains uniform λ/2 retardation across the entire clear aperture, with standard products achieving a 2×3 2D beam-splitting effect. The product is supplied as a bare die without mechanical housing and can be used with 1-inch rotation mounts to adjust the geometric orientation of the split beams.

Product Model | Operating Wavelength | Beam splitting mode | Separation angle | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| LCBS25-532-0203-025015 | 532 nm | 2×3 | 0.25 °×0.15 ° | $1,300.22 | 5 weeks | Add Cart | ||

| LCBS25-1064-0203-050030 | 1064 nm | 2×3 | 0.5 °×0.3 ° | $1,300.22 | 5 weeks | Add Cart |

- LCP/UVFS Window Plates

- Clear Aperture: Ø21.5 mm

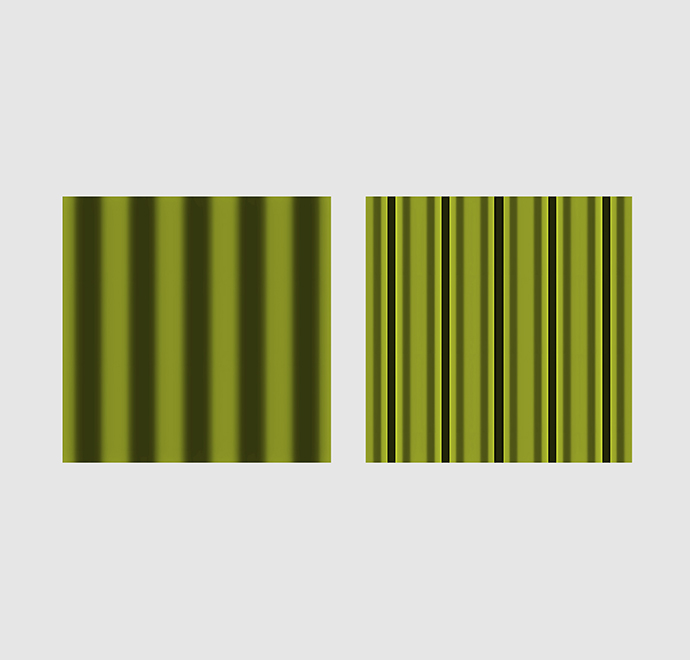

- 1×3 and 1×9 Uniform Beam Splitting Effects Available

The LBTEK one-dimensional polymer beamsplitter DOE is fabricated on a 3 mm thick fused silica window, featuring a double-layer substrate with a single-layer liquid crystal polymer film structure. It maintains a uniform λ/2 retardation across the entire clear aperture. Standard products can achieve 1×3 and 1×9 one-dimensional beam-splitting effects. The product is supplied as a bare chip without a mechanical housing and can be used with a 1-inch rotation mount to adjust the geometric orientation of the split beams.

Product Model | Operating Wavelength | Beam splitting mode | Separation angle | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| LCBS25H-532-0103-000050 | 532 nm | 1×3 | 0.5 ° | $1,248.19 | 4 weeks | Add Cart | ||

| LCBS25H-532-0109-000015 | 532 nm | 1×9 | 0.15 ° | $1,248.19 | 5 weeks | Add Cart | ||

| LCBS25H-1064-0103-000100 | 1064 nm | 1×3 | 1 ° | $1,248.19 | 4 weeks | Add Cart | ||

| LCBS25H-1064-0109-000030 | 1064 nm | 1×9 | 0.3 ° | $1,248.19 | 5 weeks | Add Cart |

- LCP/UVFS Window Plate

- Clear Aperture: Ø21.5 mm

- 2×3 Uniform Beam Splitting Effect Available

Product Model | Operating Wavelength | Beam splitting mode | Separation angle | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| LCBS25H-532-0203-025015 | 532 nm | 2×3 | 0.25 °×0.15 ° | $1,560.26 | 5 weeks | Add Cart | ||

| LCBS25H-1064-0203-050030 | 1064 nm | 2×3 | 0.5 °×0.3 ° | $1,560.26 | 5 weeks | Add Cart |