Specifications

Curve

Tutorial

Application

Customization

Feedback

Product Description

- Liquid crystal polymer/N-BK7 window plate/linear polarizing film material, three-piece flat plate structure, supplemented with mechanical housing

- High uniformity, long propagation distance, low polarization state limitation of incident light

- Optical attenuation principle, applicable to generate flat-top light with long-distance propagation

- Operating wavelengths: 532, 633 nm, incident beam diameter: 2, 4, 6 mm

- Flexible customization of parameter specifications available

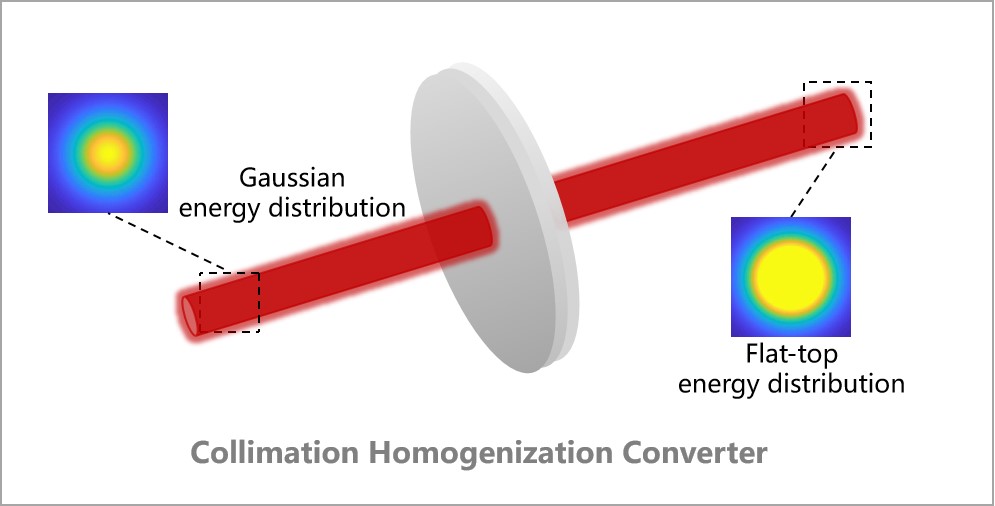

The LBTEK Collimation Homogenization Converter (CHC) achieves beam homogenization and shaping based on the principle of spatial local light attenuation. The product features a three-piece flat-plate structure and is installed in a standard SM1 lens tube. The collimation homogenization converter consists of a structured waveplate and two parallel linear polarizers arranged at a specific angle. Linearly polarized light passes through the structured waveplate to generate vector polarized light, which then undergoes partial intensity attenuation of the Gaussian beam via the rear polarizer, thereby achieving collimation and homogenization of the beam. Since the phase distribution of the structured waveplate is designed based on an ideal Gaussian beam, it requires high-quality incident light (single-mode, M² < 1.3). Compared to the LBTEK DOE homogenizer, the collimation homogenization converter can achieve flat-top beam shaping over long propagation distances, making it suitable for applications such as imaging, illumination, and long-distance laser processing. LBTEK offers standard collimation homogenization converters with working wavelengths of 532 nm and 633 nm, with optional incident beam diameters of 2 mm, 4 mm, and 6 mm. In addition to standard products, LBTEK also supports flexible customization of parameters. For specific customization requirements, please contact LBTEK Technical Support.

Diagram

Attributes

Component MaterialLiquid Crystal Polymer/N-BK7 Window Plate/Linear Polarizing Film

Incident beam qualitySingle mode, M2<1.3

Component sizeØ25.4×3.0 mm

Incident light eccentricity (XY displacement)±5% (× incident spot diameter)

Clear ApertureØ15 mm

Angle of incidence±5 °

Surface finish (scratches/pits)60/40

Uniformity of outgoing light spot>90 %(RMS)

Collimating Homogenizing Converters

- Liquid Crystal Polymer/N-BK7 Window Plate/Linear Polarizing Film

- Clear Aperture: Ø15 mm

- Capable of Generating Flat-top Light for Long-distance Propagation

The LBTEK collimating homogenizing converter consists of a structured waveplate and front/rear parallel linear polarizers, presenting a three-plate flat structure that utilizes the principle of spatial localized light intensity attenuation to achieve beam homogenization and shaping. The standard product is mounted in a standard SM1 lens tube, with engraved markings on the tube surface indicating the transmission axis of the polarizers. The tube also bears the product name and specification parameters for convenient adjustment and use in optical setups. Since both front and rear linear polarizers have parallel transmission axes, the collimating homogenizing converter has no requirements on the polarization state of incident light and can be used from either side. However, for maximum light energy utilization, it is recommended to use linearly polarized light with its polarization direction parallel to the polarizers' transmission axis.

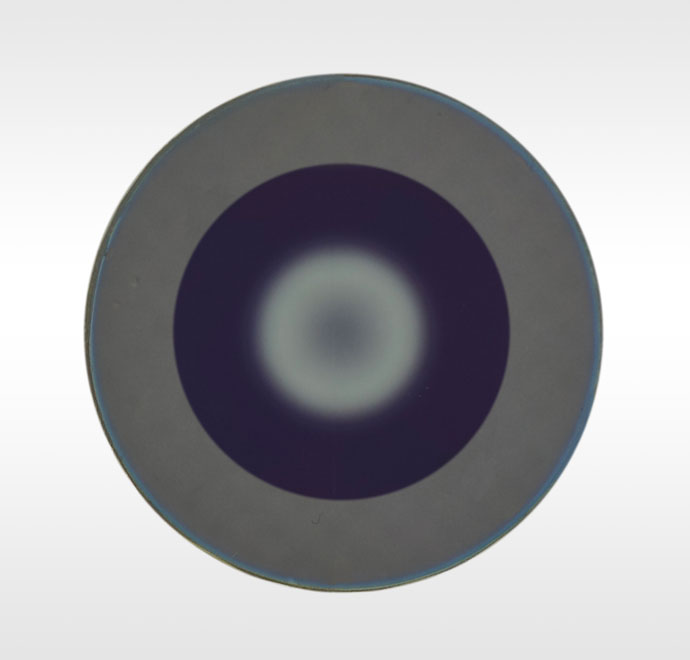

Collimating and Homogenizing Converter Waveplate Section Phase Structure

Product Model | Operating Wavelength | Incident spot diametera | Output beam diameterb | Unit Price | Compare | Lead Time | ||

|---|---|---|---|---|---|---|---|---|

| CHC25-532-2-FTC2 | 532 nm | Ø2 mm | Ø2 mm | $1,213.54 | 4 weeks | Add Cart | ||

| CHC25-532-4-FTC4 | 532 nm | Ø4 mm | Ø4 mm | $1,213.54 | 4 weeks | Add Cart | ||

| CHC25-532-6-FTC6 | 532 nm | Ø6 mm | Ø6 mm | $1,213.54 | 4 weeks | Add Cart | ||

| CHC25-633-2-FTC2 | 633 nm | Ø2 mm | Ø2 mm | $1,213.54 | 4 weeks | Add Cart | ||

| CHC25-633-4-FTC4 | 633 nm | Ø4 mm | Ø4 mm | $1,213.54 | 4 weeks | Add Cart | ||

| CHC25-633-6-FTC6 | 633 nm | Ø6 mm | Ø6 mm | $1,213.54 | 4 weeks | Add Cart |